Fixture for zinc-spraying of circular coil

A technology for toroidal coils, fixtures, used in injection devices, coil manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

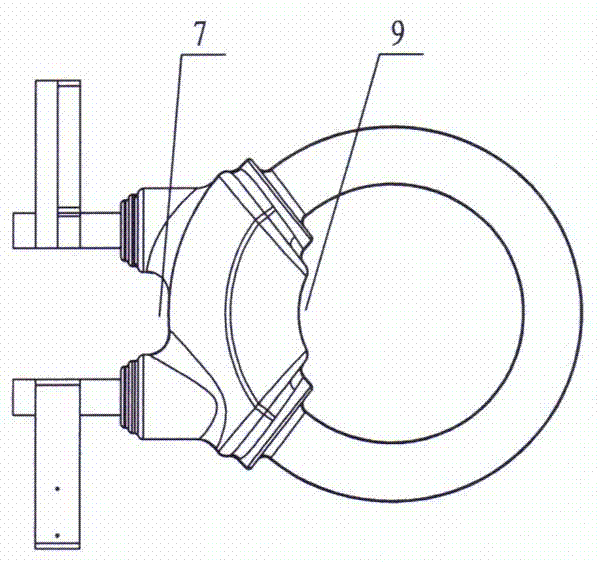

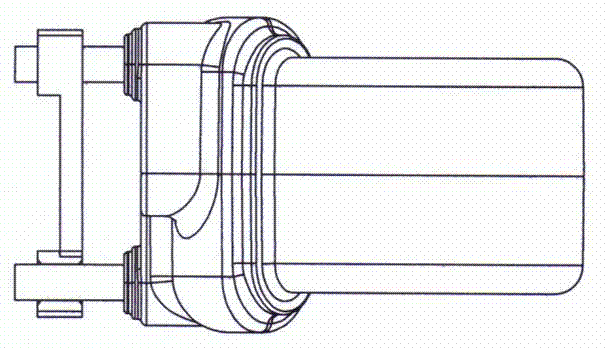

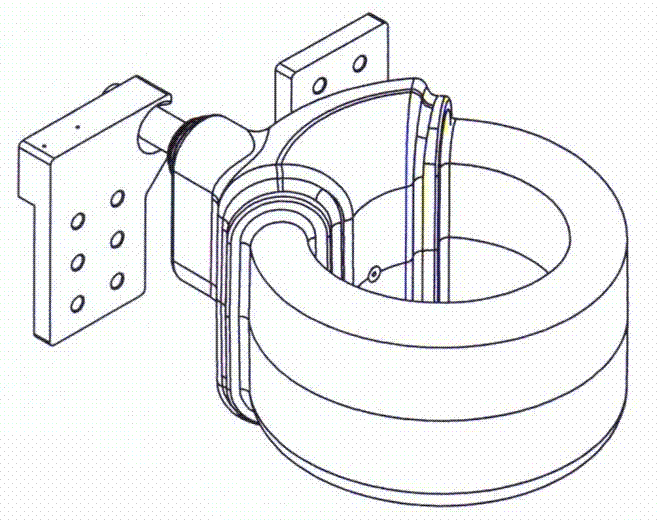

[0025] Figure 4 , Figure 5 It is a schematic diagram of the structure of the fixing device for zinc spraying of the ring coil. As can be seen from the figure, it includes a circular turntable 1, and the middle of the turntable 1 is provided with a square hole 2 that can put the non-galvanized part of the coil. The hole 2 behind the turntable 1 is fixed with a square connecting frame 3 with an open end. The open end of the connecting frame 3 is fixed to the turntable 1. Two fork-shaped connecting plates 4 protrude from the upper and lower sides of the hole 2. The coil 5 is placed on the On the connection plate 4, the rear end of the connection plate 4 is fixed with an upright support plate 6 such as Figure 6 shown. When the coil 5 is installed, the concave back 7 of the coil 5 is against the supporting plate 6, and the front end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com