Rotary microporous aeration circular coil system for treating sewage

A microporous aeration and sewage treatment technology, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problem of uneven horizontal and vertical distribution of dissolved oxygen, high density of microporous aeration tube arrangement, and turbulent diffusion of air bubbles Weak effect and other problems, to achieve uniform distribution of dissolved oxygen in water, strengthen the turbulent diffusion of air bubbles, and quickly distribute uniformly in the lateral direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

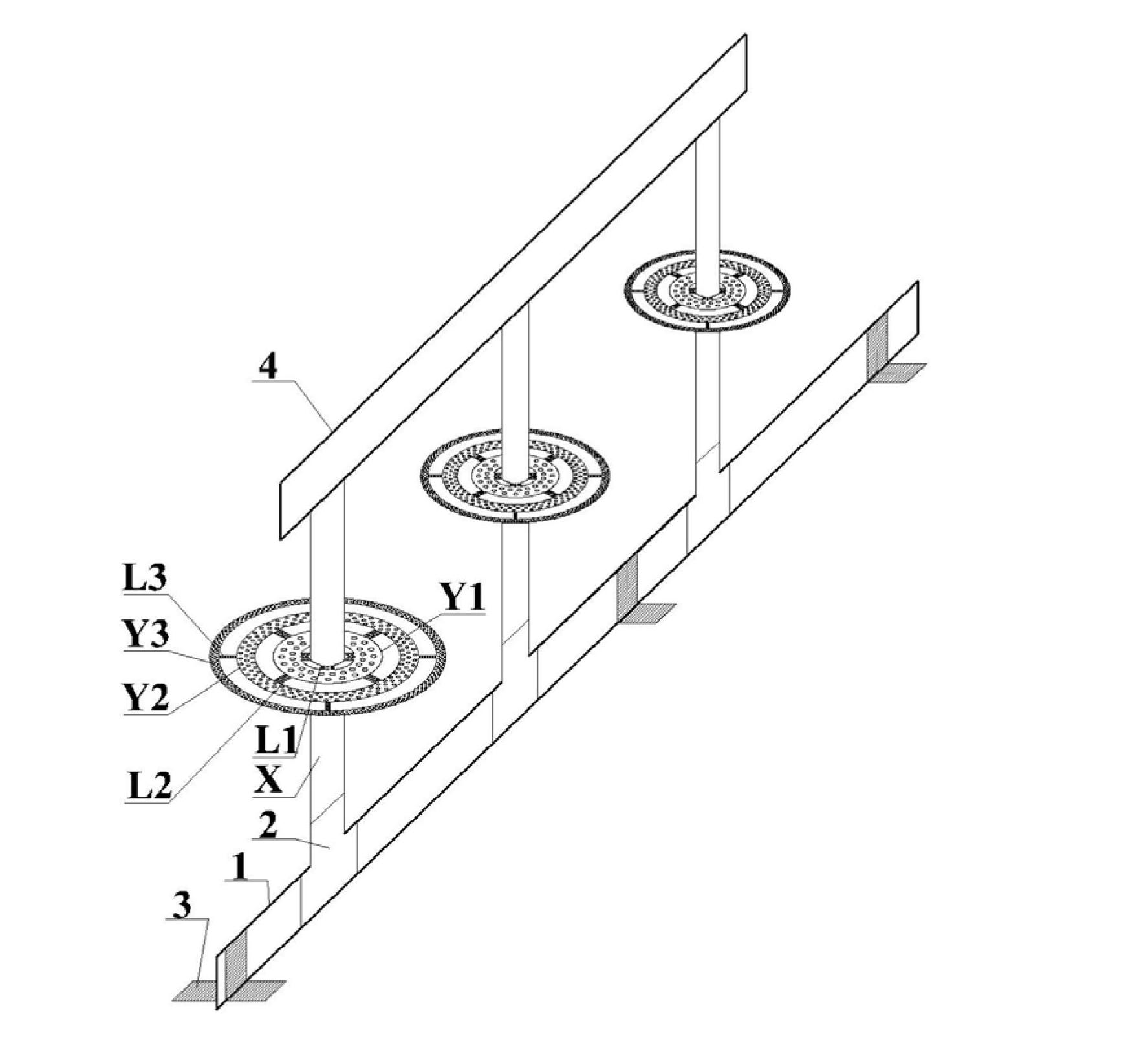

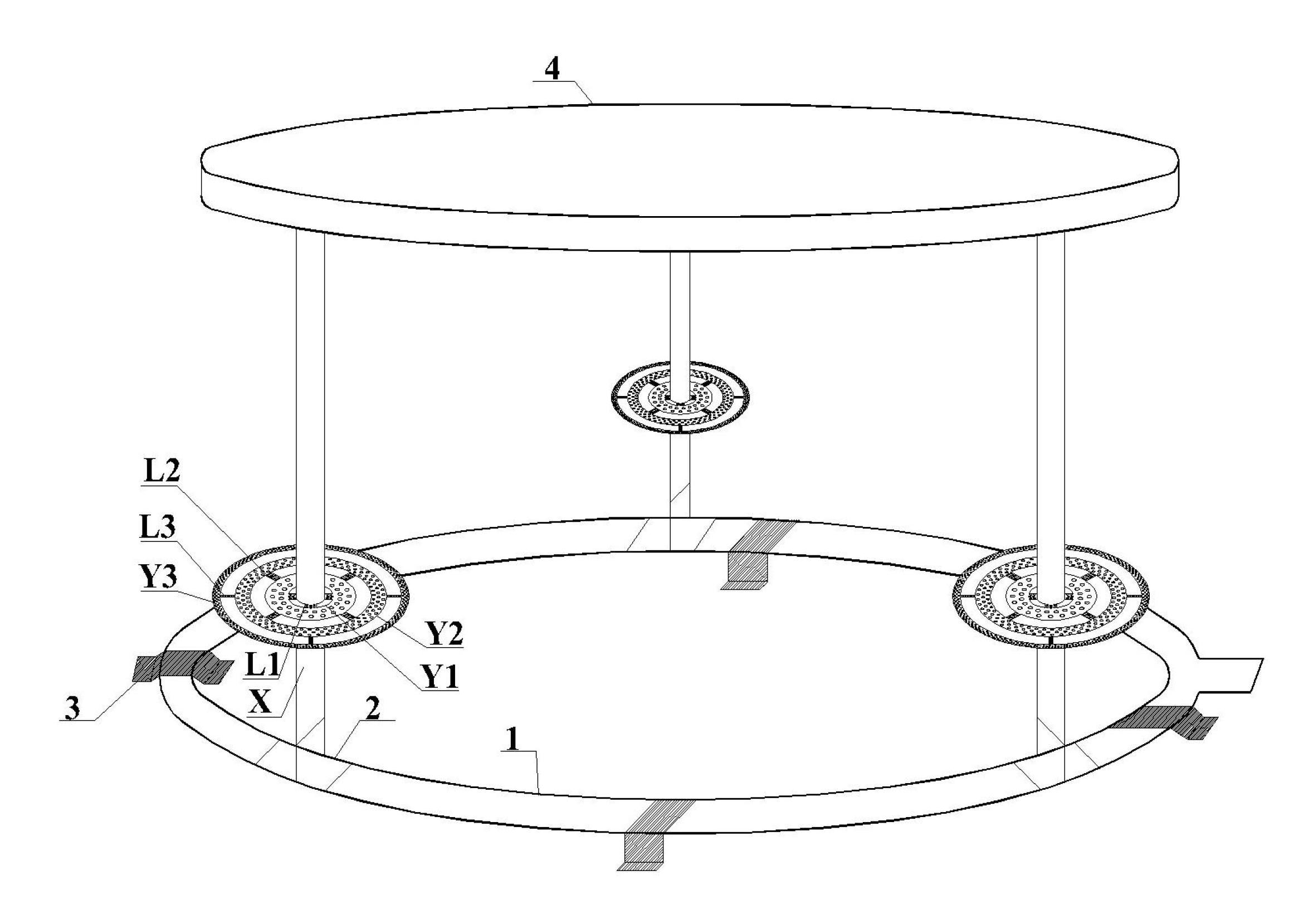

[0015] Now take three microporous circular tubes and twelve microporous communicating tubes connected into one coil and connected with the vertical rotating main tube to form a microporous concentric circular coil group as an example, and further illustrate how the present invention is implemented in conjunction with the accompanying drawings of:

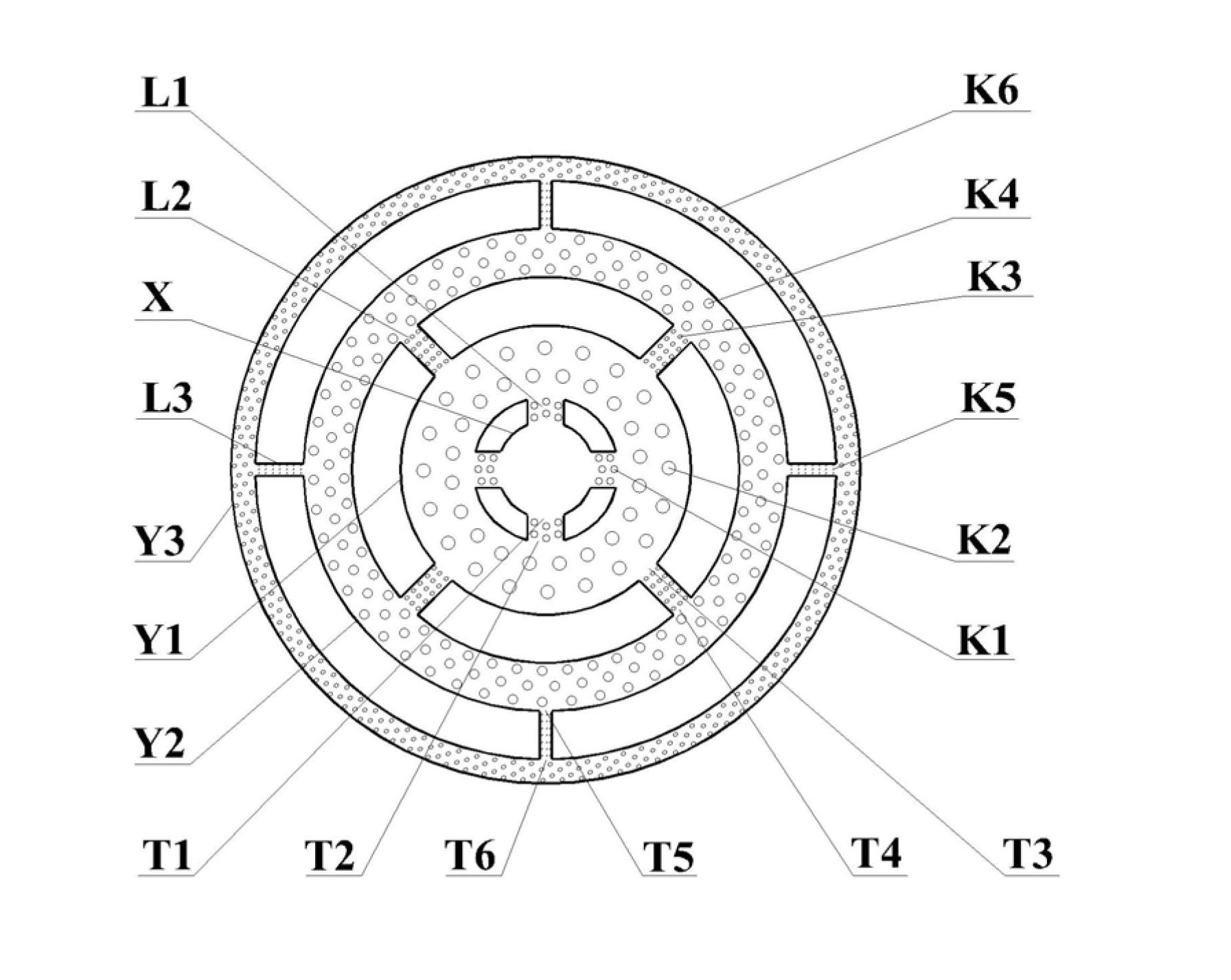

[0016] The microporous concentric ring coil group is composed of horizontal microporous concentric circular tubes Y1, Y2, Y3, vertically rotating main tube X, microporous connecting tubes L1, L2, L3, and microporous connecting tubes L1, L2, L3 each four The roots are vertically and symmetrically connected in pairs between X and Y1, Y1 and Y2, Y2 and Y3, and the tubes of L1, L2 and L3 are evenly spaced. The microporous connecting pipe L1, the vertically rotating main pipe X, and the microporous circular pipe Y1 have communicating holes T1 and T2 respectively; the microporous connecting pipe L2 and the microporous concentric circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com