Superconducting coil

A technology of superconducting coils and superconducting wires, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve problems such as degradation of superconducting characteristics, and achieve the effect of improving stability and preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

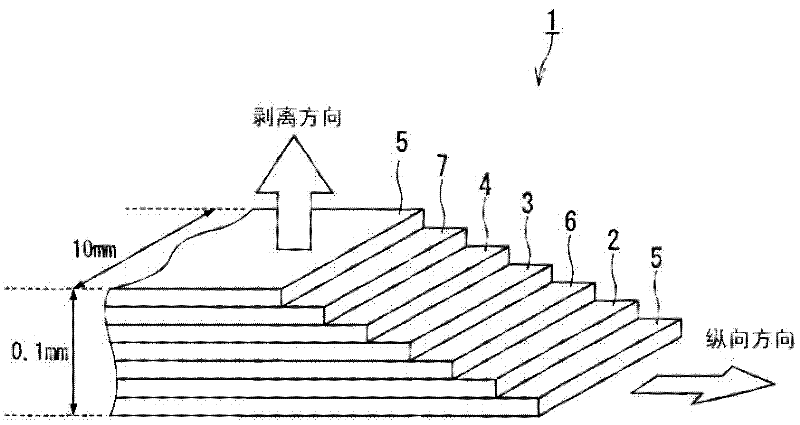

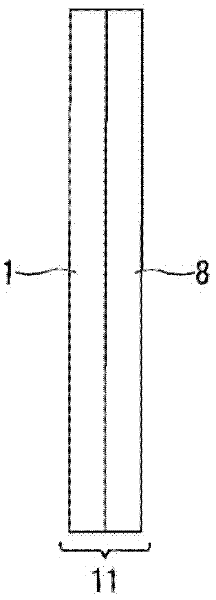

[0056] The following will refer to Figure 6 ( Figure 6A and 6B ) describes a superconducting coil according to a first embodiment of the present invention.

[0057] Referring to FIG. 6 , superconducting coil 10 is formed by, for example, disposing superconducting coil portion 14 on the outer surface of FRP core 19 . The superconducting coil portion 14 has an outer (outermost) diameter of 400 mm and an inner (innermost) diameter of 100 mm. The FRP core 19 has an outer diameter of 100 mm and an inner diameter of 90 mm, and includes a linear portion with a length of 150 mm. Figure 6A and 6B An illustrated example is a case where the width dimension of the superconducting coil 10 is an oval shape. In the case of oval shapes, the length dimensions can be compared with each other.

[0058] The superconducting coil portion 14 includes concentric three-coil layer portions (areas) which are coplanar with each other or arranged in a flat plate form. The three-coil layer part is ...

no. 2 example

[0069] Below, will refer to Figure 7 A superconducting coil according to a second embodiment of the present invention is described, wherein the same configurations (parts or elements) as in the first embodiment are denoted by the same reference numerals and explanations thereof are omitted.

[0070] exist Figure 7 In this example of Figure 6A and 6B 750 turns of the composite tape 11 were wound as in the superconducting coil 10 of the second embodiment to form the superconducting coil 20 of the second embodiment. Except that the FRP tape 23 is inserted between the outer surface of the composite tape 11 at the 125th turn of the superconducting coil part 14 and the inner surface of the composite tape 11 at the 126th turn and between the outer surface of the composite tape 11 at the 375th turn and the inner surface of the composite tape 11 at the 375th turn. Outside between the inner surfaces of the composite tape 11 at the 376th turn, Figure 7 The superconducting coil 20...

no. 3 example

[0076] The following will refer to Figure 8 A superconducting coil according to a third embodiment of the present invention is described, wherein the same configurations as those in the first and second embodiments are denoted by the same reference numerals and explanations thereof are omitted.

[0077] In this example, the superconducting coil 30 of the third embodiment was formed by winding the composite tape 11 for 750 turns as in the superconducting coil 10 in FIG. 6 . Except that the cooling / insulating tape 33 is inserted between the outer surface of the composite tape 11 at the 125th turn of the superconducting coil portion 14 and the inner surface of the composite tape 11 at the 126th turn and outside the composite tape 11 at the 375th turn. surface and the inner surface of the composite tape 11 at the 376th turn, Figure 8 The superconducting coil 30 is the same as the superconducting coil 10 of the first embodiment.

[0078] Such as Figure 9 As shown in , the coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com