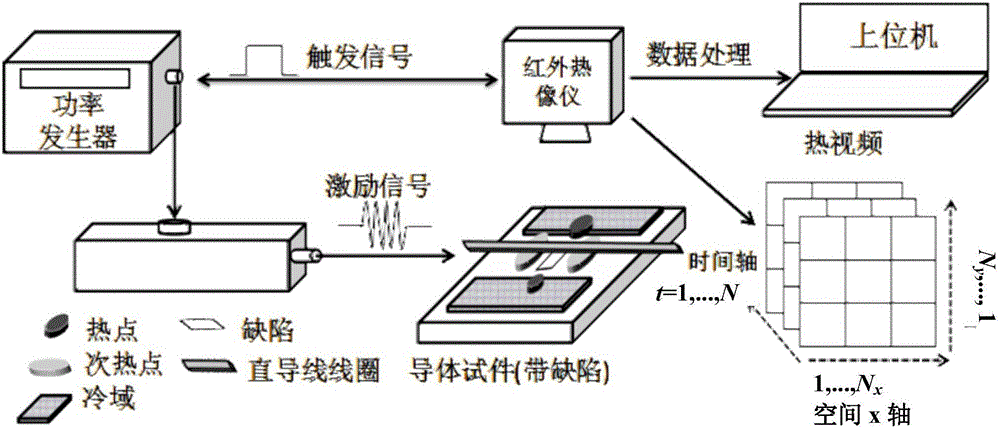

Inductive thermal image nondestructive testing device based on commensal type magnet yoke coil

A yoke coil and non-destructive testing technology, which is applied in the field of induction thermal imaging non-destructive testing devices, can solve the problems of small magnetic induction intensity, small detectable area, low defect detection efficiency, etc., so as to improve temperature contrast and improve defect detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

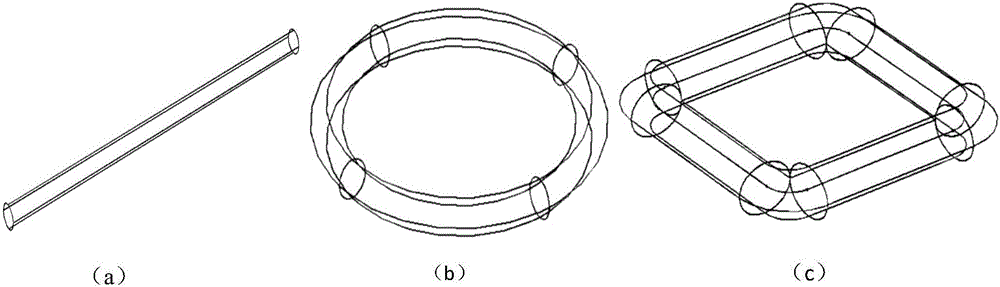

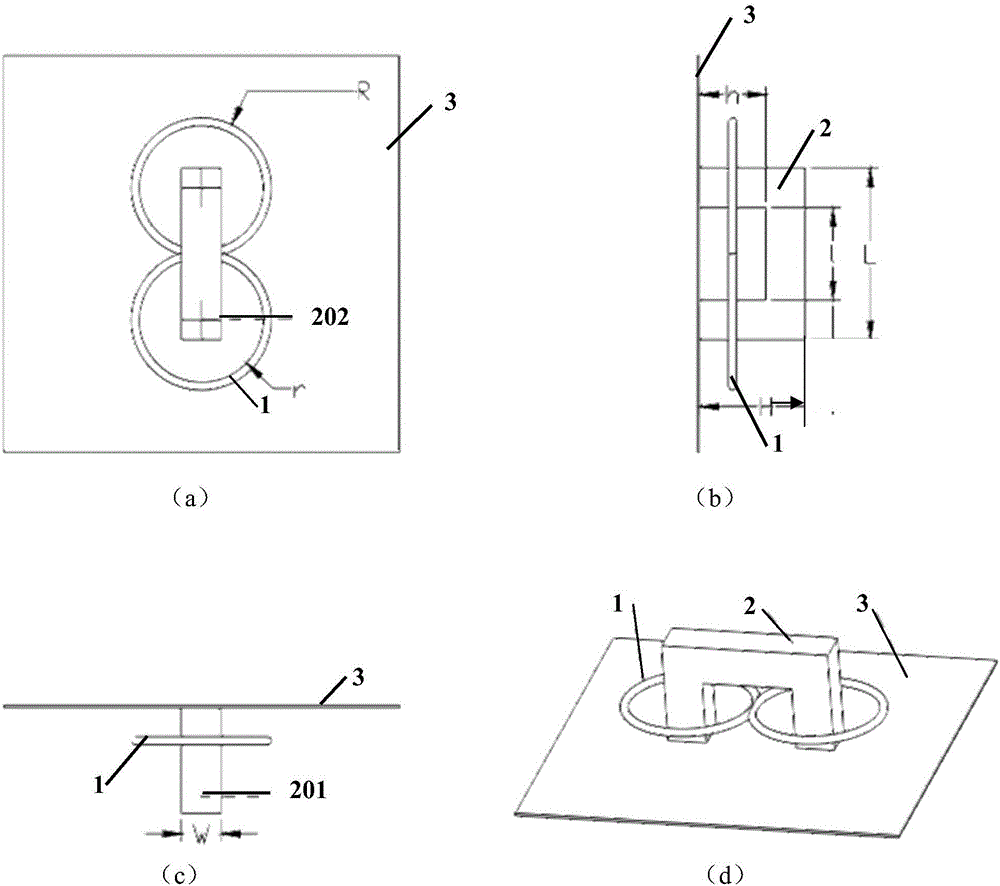

[0026] image 3 It is a structural diagram of a specific embodiment of the novel symbiotic yoke coil adopted in the present invention. In this example, if image 3 As shown, the symbiotic yoke coil in the present invention includes a "冂" shaped yoke 2 and an excitation coil 1 .

[0027] The excitation coil 1 is composed of two equivalent toroidal coils, and the two equivalent toroidal coils are cross-connected in a figure of eight, and the winding direction is type, and the magnetic fields generated by the two equivalent toroidal coils strengthen each other, which is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com