Molten steel flow-speed measurement method and device based on electromagnetic tomography

A technology of electromagnetic tomography and flow velocity measurement, which is applied in the directions of measuring devices, fluid velocity measurement, velocity/acceleration/shock measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

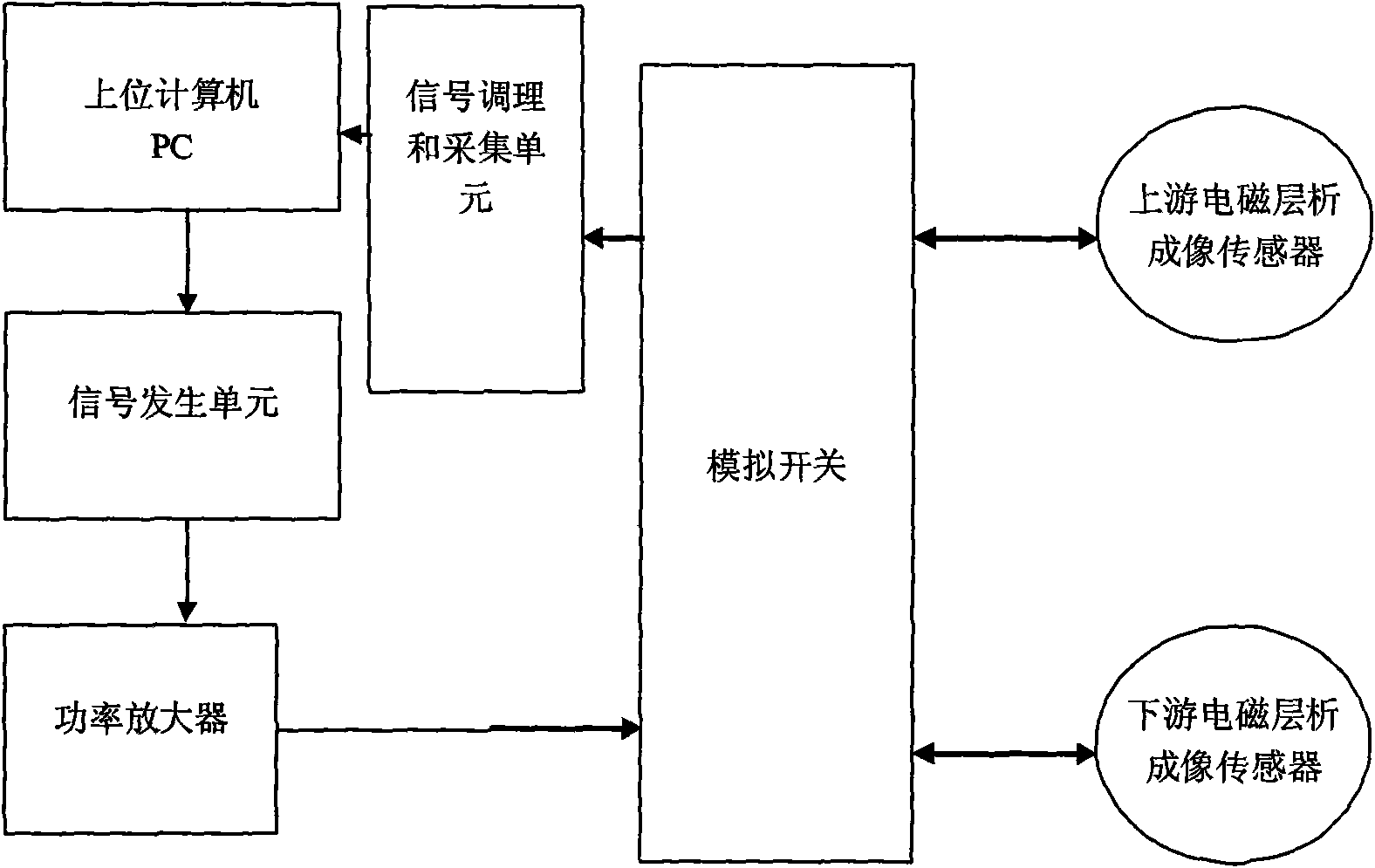

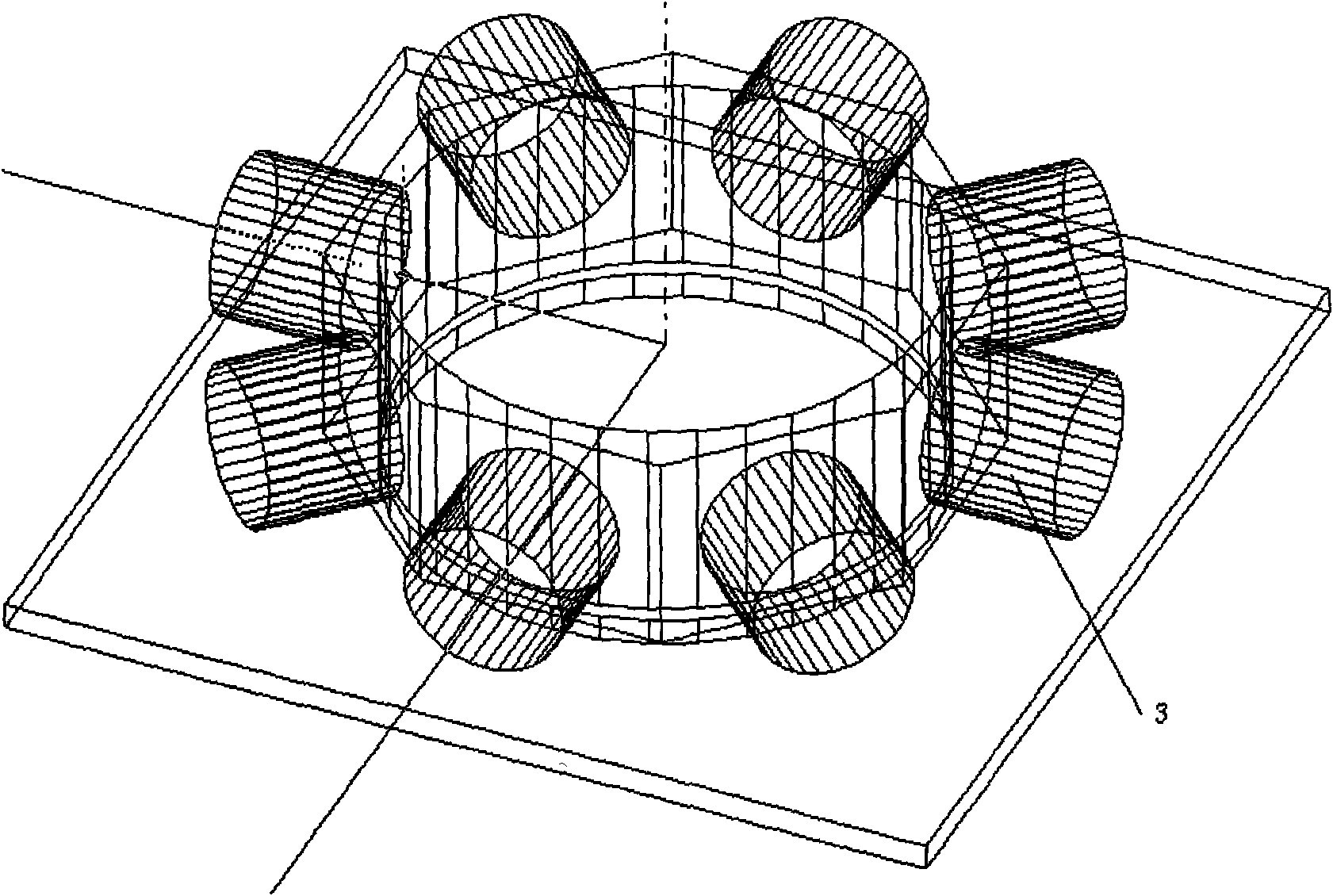

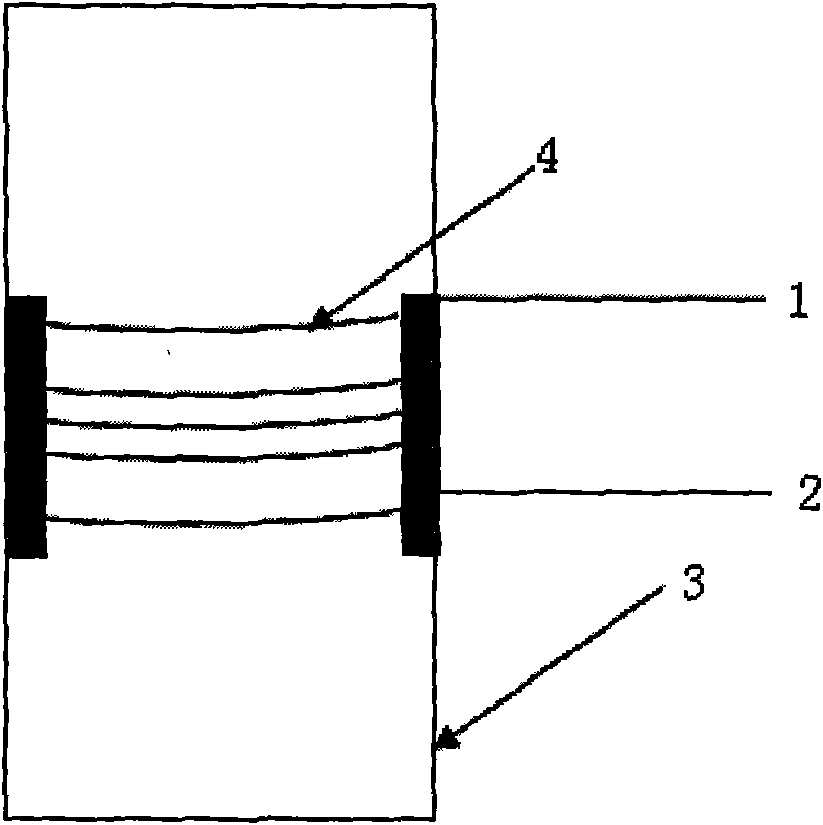

[0028] figure 1 There are a total of two electromagnetic tomography sensors installed upstream and downstream of the molten steel, and each sensor consists of a plurality of annular coil arrays evenly distributed on the same section. The signal generating unit adopts the direct digital synthesis (DDS) chip AD7008, which can generate sinusoidal excitation signals of different amplitudes and phases. The amplitude and phase of the excitation signal can be set by the computer, amplified by the power amplifier, and then installed on the excitation coil gated by the analog switch.

[0029] The computer controls the signal conditioning and acquisition unit to acquire the data sequence of the mutual inductance of the upstream and downstream sensors, wherein the sequence is controlled by the analog switch. Typically for the electromagnetic tomography...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com