Air Handling Unit That Eliminates Corner Singularities and Eddies for High Energy Efficiency and Its Evaporator Heat Exchanger Coil Arrangements

a technology of evaporator heat exchanger and air handling unit, which is applied in the direction of lighting and heating apparatus, liquid fuel engines, heating types, etc., can solve the problems of weak concentric flow recirculation or eddies, energy dissipation in form of heat within the chamber, and decrease in so as to improve the efficiency and improve the performance. , the effect of reducing the efficiency of the air conditioning system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]All illustrations of the drawings are for the purpose of describing selected versions of the present invention and are not intended to limit the scope of the present invention. The present invention is to be described in detail and is provided in a manner that establishes a thorough understanding of the present invention. There may be aspects of the present invention that may be practiced without the implementation of some features as they are described. It should be understood that some details have not been described in detail in order to not unnecessarily obscure focus of the invention.

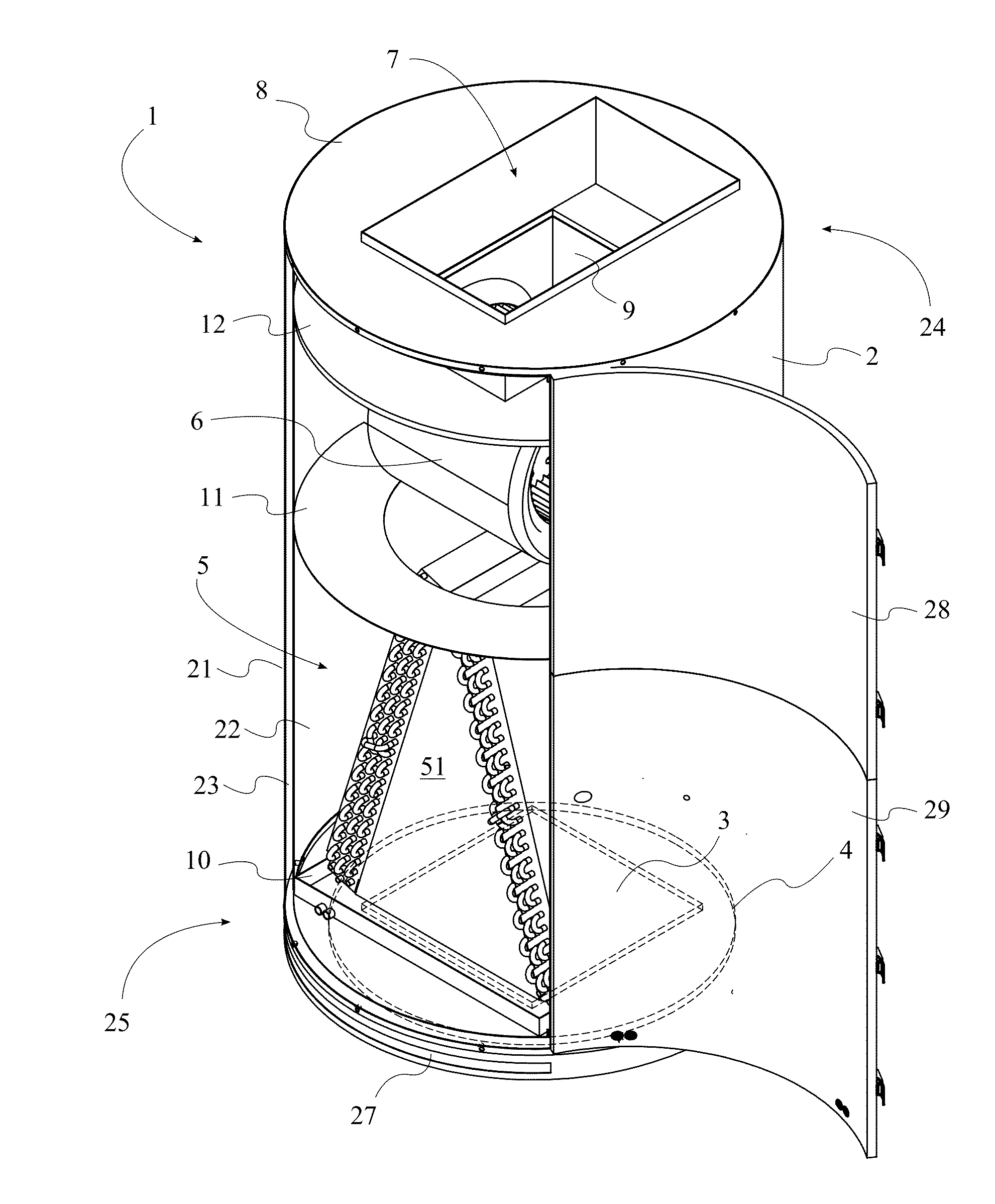

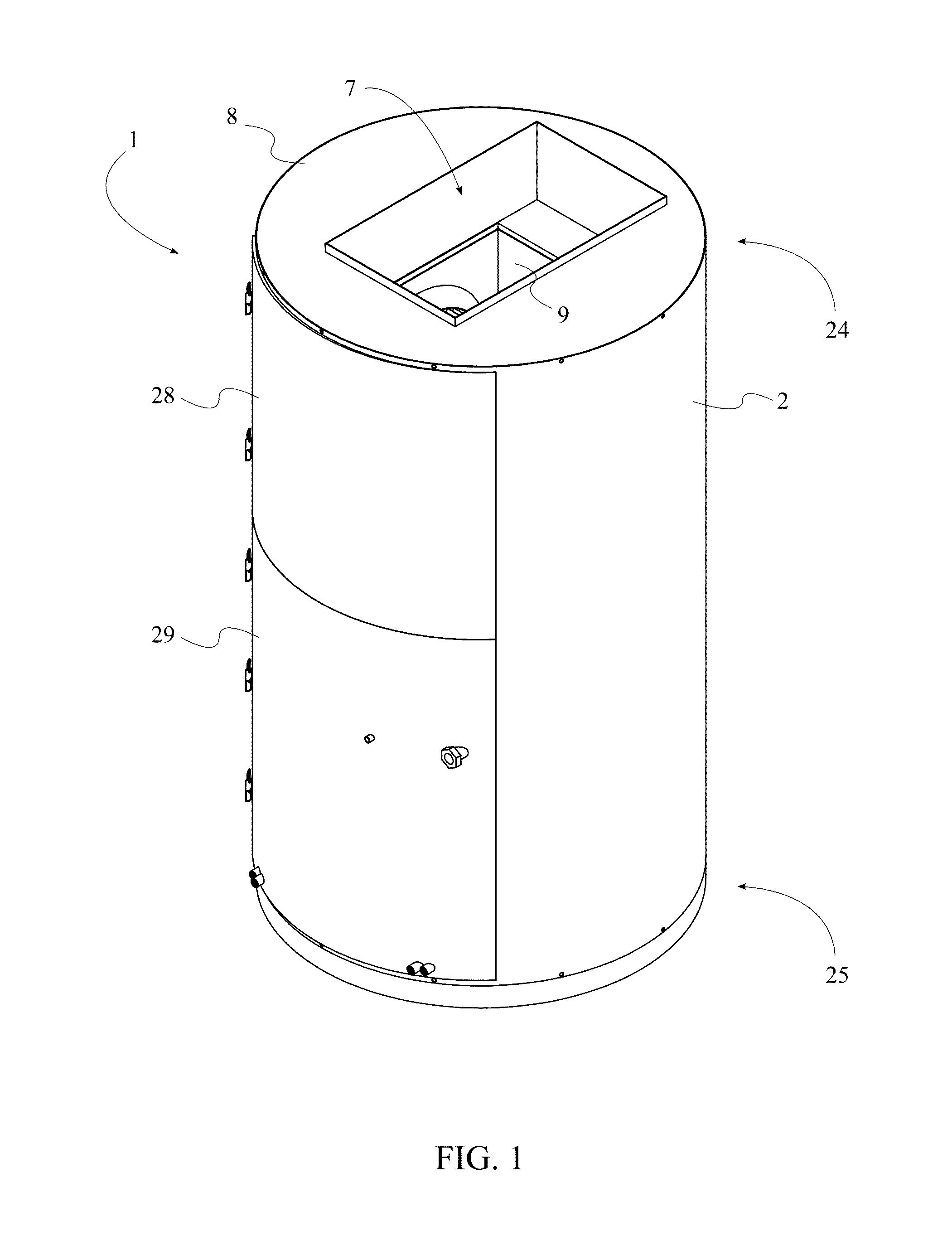

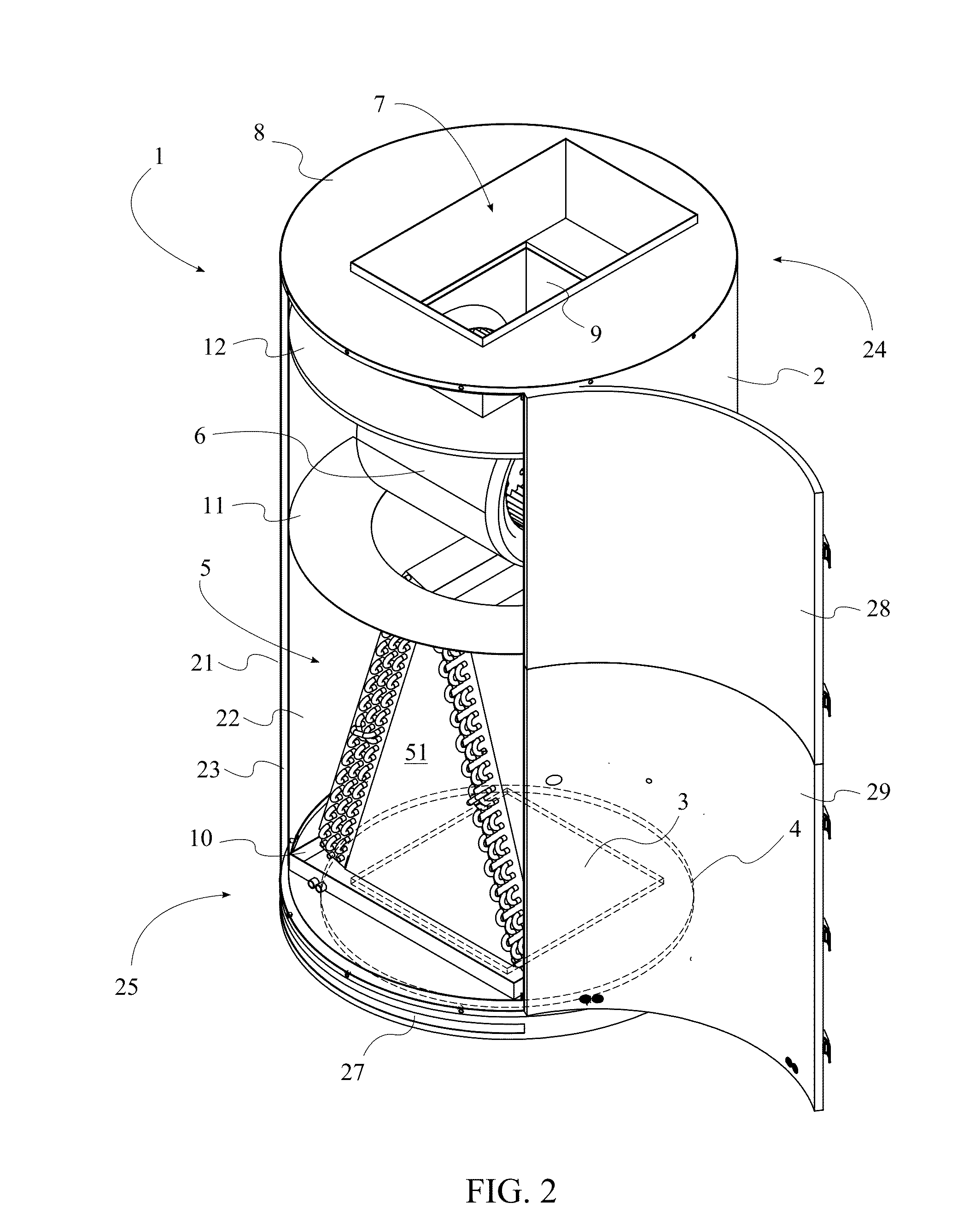

[0035]The present invention is an air handling unit 1, which is a major component of a split system central air conditioning or heat pump, and its functions include generating, controlling and circulating conditioned air through a transport and distribution system to the building or structure where the unit operates in conjunction with an outdoor condensing unit. The air handling unit 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com