Ultrasonic guided wave device and method for detecting defect at rail bottom of steel rail at long distance

An ultrasonic guided wave, long-distance technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, and the analysis of materials using sonic emission technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

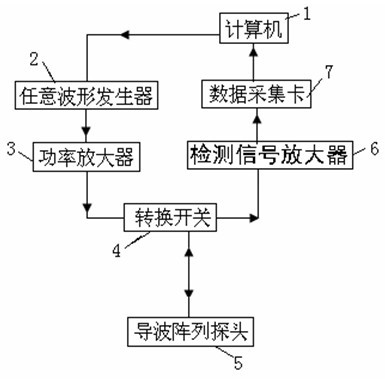

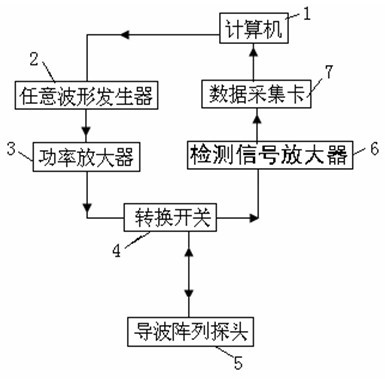

[0016] Such as figure 1 As shown, the present invention is realized in this way, the computer (1) is connected to the data acquisition card (7) and the arbitrary waveform generator (2), the data acquisition card (7) is connected to the detection signal amplifier (6), and the arbitrary waveform generator ( 2) Connect the power amplifier (3), the power amplifier (3) is connected to the transfer switch (4), and the transfer switch (4) is connected to the guided wave array probe (5) and the detection signal amplifier (6). The ultrasonic guided wave array probe (5) is composed of four low-frequency ultrasonic high-damping sub-probes. The low-frequency ultrasonic guided wave array probe (5) is placed vertically on the bottom side of the rail, and the center distance between the sub-probes is ,in is the guided wavelength. Each sub-probe is assembled in the probe box. The surface layer of the probe box is made of a steel plate with a certain thickness. When testing, hold the probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com