Rack pipe detection robot based on ultrasonic guided wave technology

An ultrasonic guided wave and tube detection technology, which is applied in the direction of manipulators, motor vehicles, pipeline systems, etc., can solve the problems of dangerous detection personnel, low detection efficiency, complex structure, etc., and achieve simple construction and disassembly, simple and easy control, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

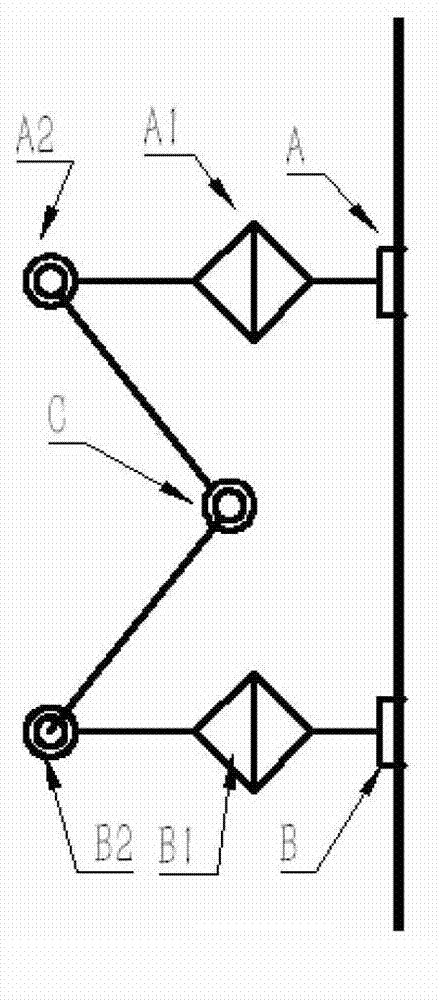

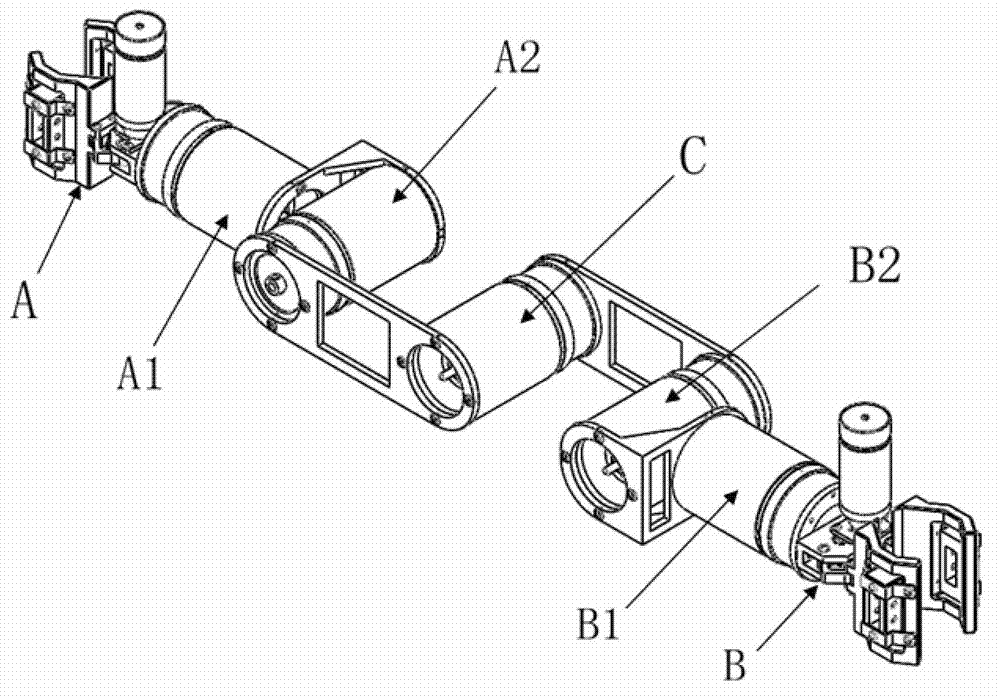

[0053] In terms of overall structural design, the present invention provides a modular two-hand claw climbing robot, such as figure 1 with figure 2 As shown, the robot adopts a modular structure. The pipe inspection robot adopts five rotational degrees of freedom and two grippers. There are two types of seven modules in total. Each module is connected in series, and the order is as follows: the first gripper A -First Rotation Module A1-Second Rotation Module A2-Third Rotation Module C-Fourth Rotation Module B2-Fifth Rotation Module B1-Second Holder B, detection probes can be installed on the two holders, the first One holder A coincides with the axis of the first rotation module A1, the second holder B coincides with the axis of the fifth rotation module B1, and the axis of the second rotation module A2, the third rotation module C, and the fourth rotation module B2 In parallel, the axes of the first rotating module A1 and the fifth rotating module B1 are perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com