A robot clamping module

A technology of robots and grippers, which is applied in the field of robot gripping modules, can solve the problems of difficult installation and disassembly, bulkiness, and insufficient realization of robot configuration flexibility and quickness, so as to reduce damage to motors and build And the effect of simple disassembly and assembly, easy to expand and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

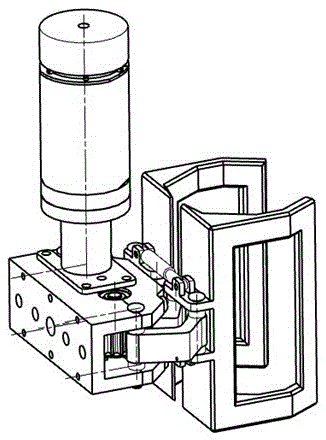

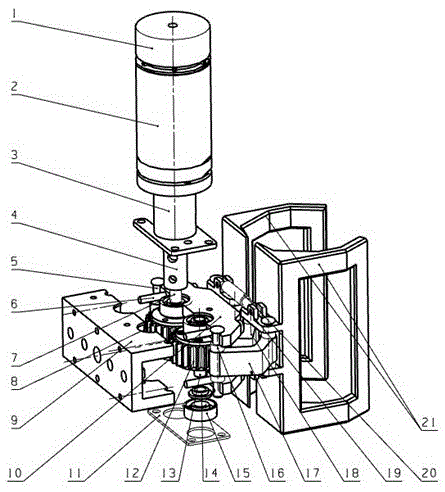

[0021] In the present invention, a robot clamping module is provided. In order to meet the requirements of simple and compact structure, convenient module function expansion, self-clamping and self-locking, multi-module loading and application requirements, the robot clamping module uses a disc motor, The planetary gear reducer, the gripper transmission assembly, the jaw assembly and the locking mechanism realize the movement and gripping functions. The gripper module is driven by a disc motor, and the torque is transmitted to the gear after passing through the planetary reducer. Through the meshing of the two gears, the inner connecting rod fixed on the gear is driven to rotate. The disassembled platform and the gripper form a parallelogram mechanism to realize the clamping and releasing functions of the gripper, and the locking mechanism realizes automatic locking in the gripping state when the gripper is opened or closed.

[0022] In the present invention, the appearance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com