Underwater pipe polishing device

An underwater pipeline and pipeline technology, which is applied in the directions of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that the operation efficiency cannot meet the operation requirements, the operation environment is dangerous, and the skill requirements are high, and the adaptability of a certain pipe diameter can be achieved. , High cleaning efficiency, the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] The preferred embodiment of the underwater pipeline grinding device of the present invention is:

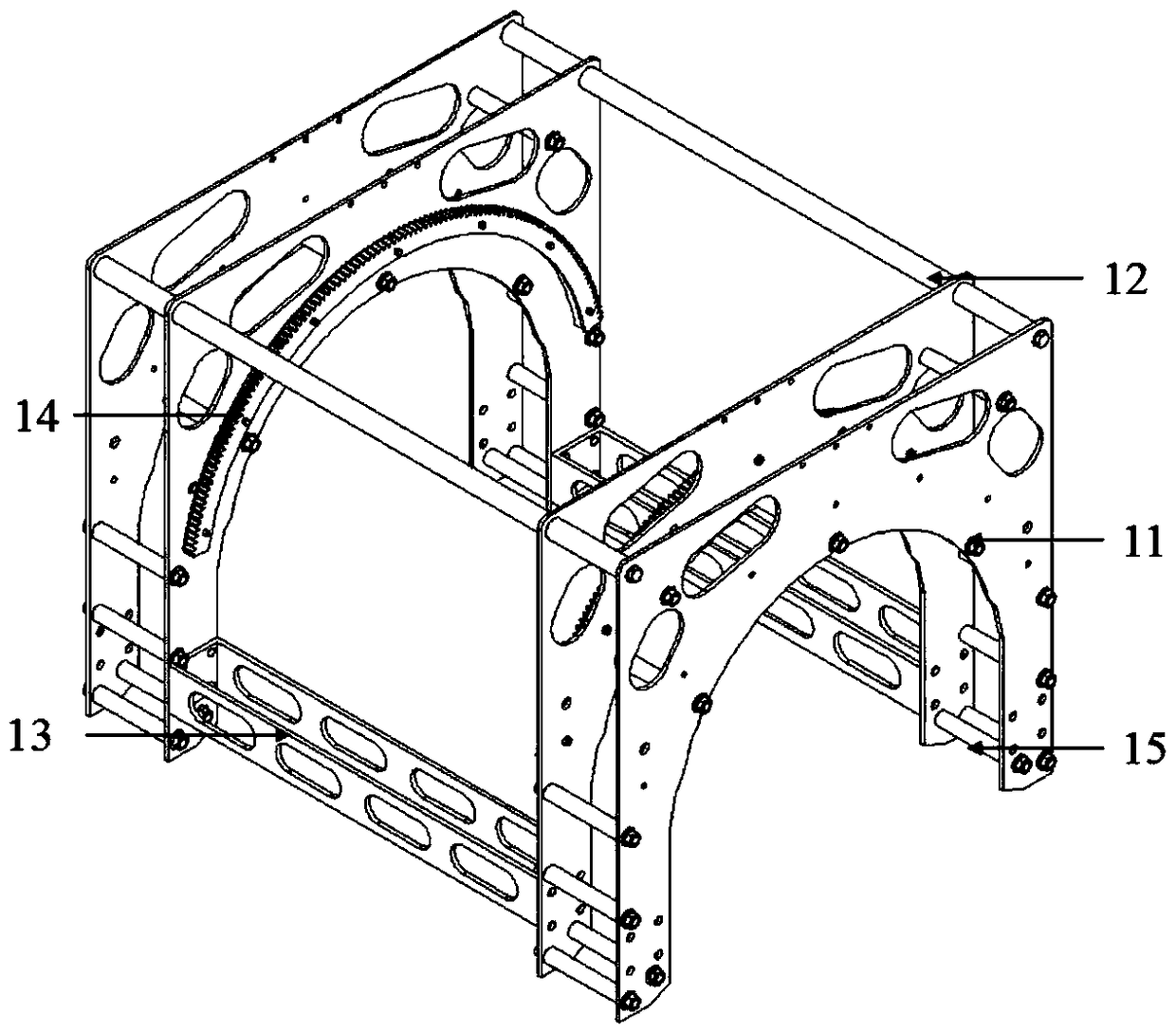

[0015] Including the equipment frame structure, the equipment frame structure includes a rack shell, the rack shell includes four aluminum alloy plates, the middle two aluminum alloy plates are connected by frame connecting rods and transverse connecting plates, and the two ends of the two The aluminum alloy plates are connected by frame mounting bolts, and the inner surfaces of the two aluminum alloy plates in the middle are provided with ring gears;

[0016] A pipe clamping mechanism is provided between the two aluminum alloy plates at both ends, and a walking brushing mechanism is provided between the two aluminum alloy plates in the middle.

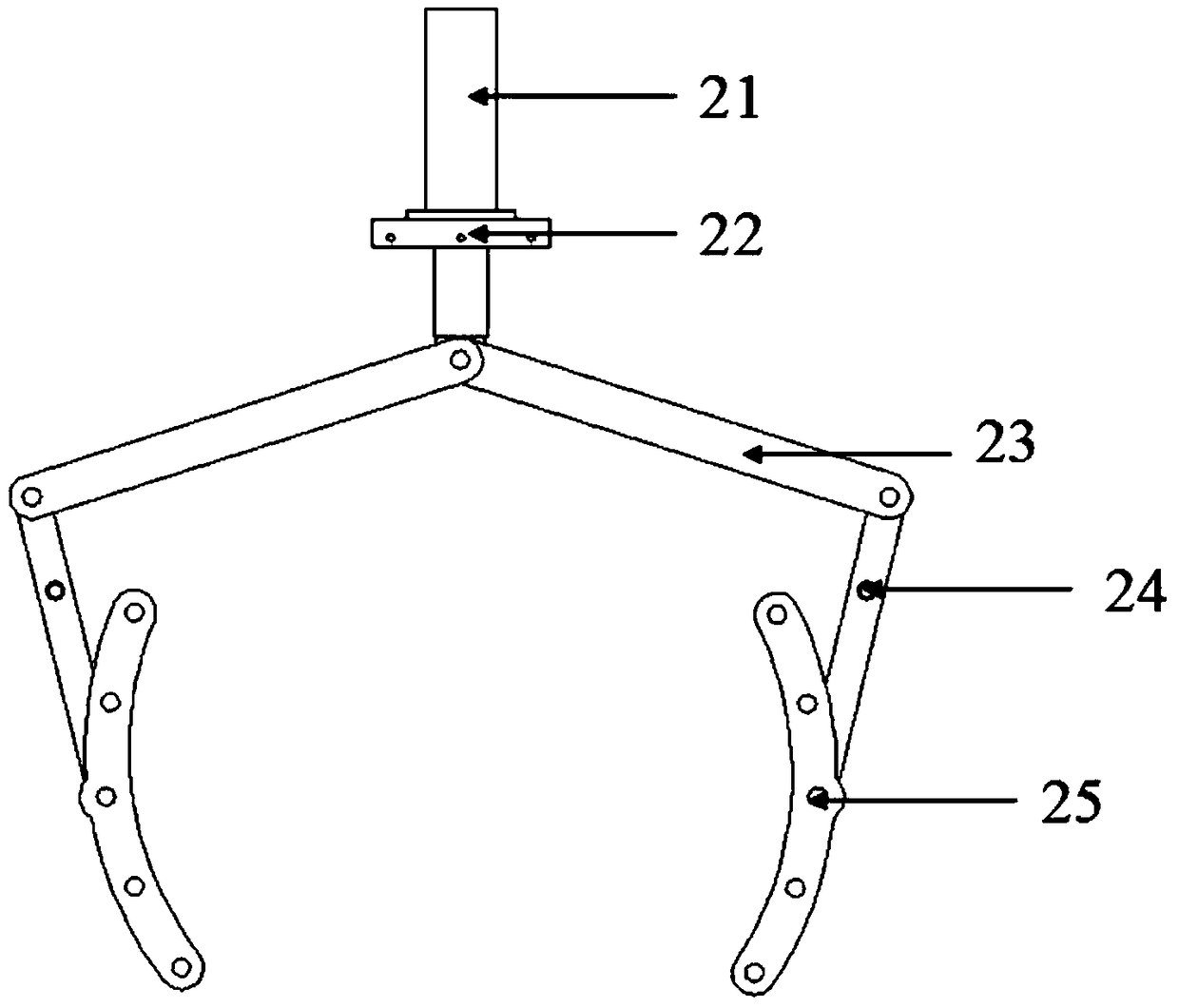

[0017] The pipeline clamping mechanism includes a clamping hydraulic cylinder and a clamping hydraulic cylinder mounting frame, the cylinder rod of the clamping hydraulic cylinder is connected with a pair of connecting rod clampin...

specific Embodiment

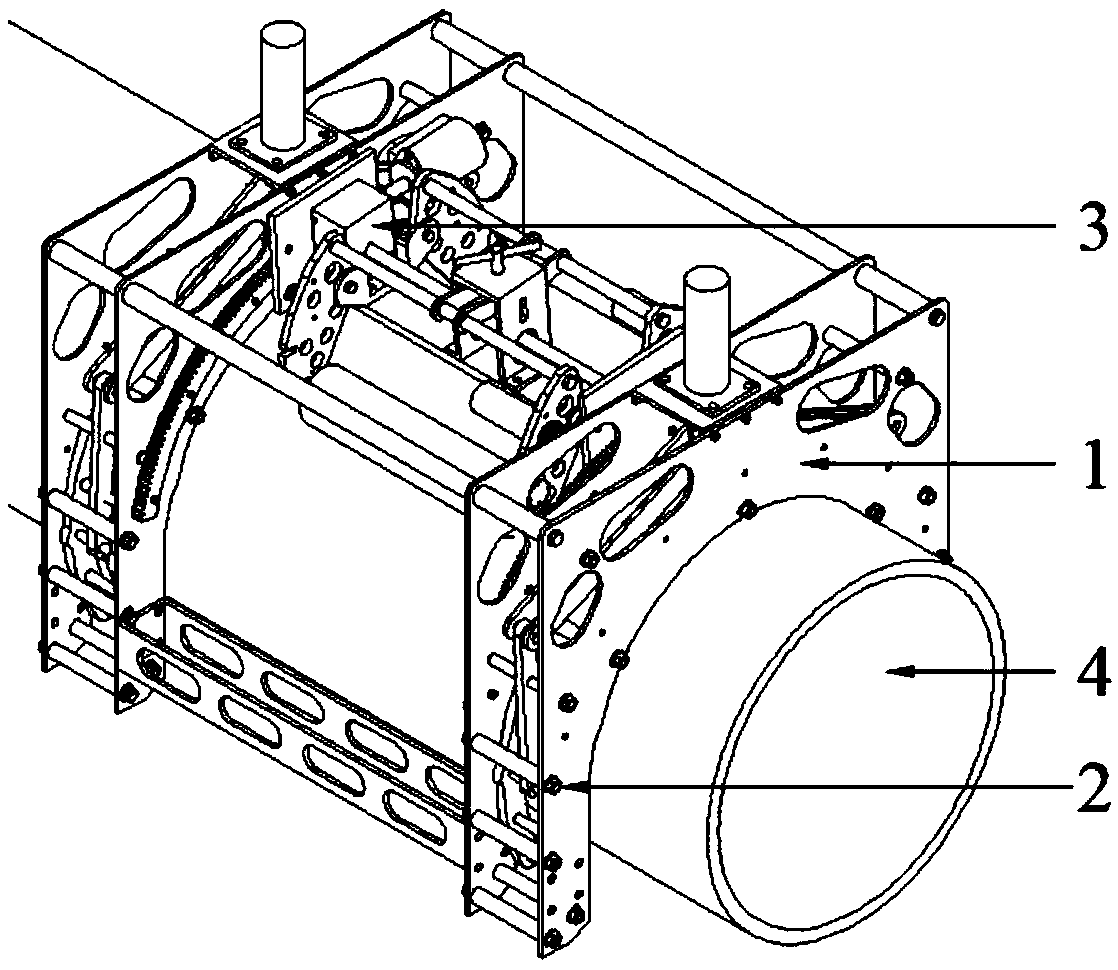

[0024] Such as Figure 1 to Figure 4 As shown, it includes an equipment frame structure 1, a pipe clamping mechanism 2 is provided in the middle of the frame shells 11 on both sides of the equipment frame structure 1, and a walking brushing mechanism 3 is provided at the inner end of the equipment frame structure 1.

[0025] The equipment frame structure mainly includes a frame shell 11 , frame connecting rods 12 , transverse connecting plates 13 , ring gear 14 , and frame mounting bolts 15 .

[0026] The pipeline clamping mechanism mainly includes a clamping hydraulic cylinder 21, a clamping hydraulic cylinder mounting frame 22, an upper rod member 23 of a linkage mechanism, a connecting rod rotating shaft support 24, and a clamping wheel support 25.

[0027] The brush tube mechanism mainly includes a wire brush hydraulic motor 37, a steel brush bracket 315, a steel brush fixing plate 36, a structural support frame 31, a traveling hydraulic motor 312, a reducer 313, a traveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com