Ultrasonic guided wave combined type nondestructive testing method and ultrasonic guided wave combined type nondestructive testing device

An ultrasonic guided wave, non-destructive testing technology, applied in the direction of material analysis using sonic emission technology, can solve problems such as unsatisfactory excitation effect, low detection sensitivity of reflected echo, and large ultrasonic guided wave attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

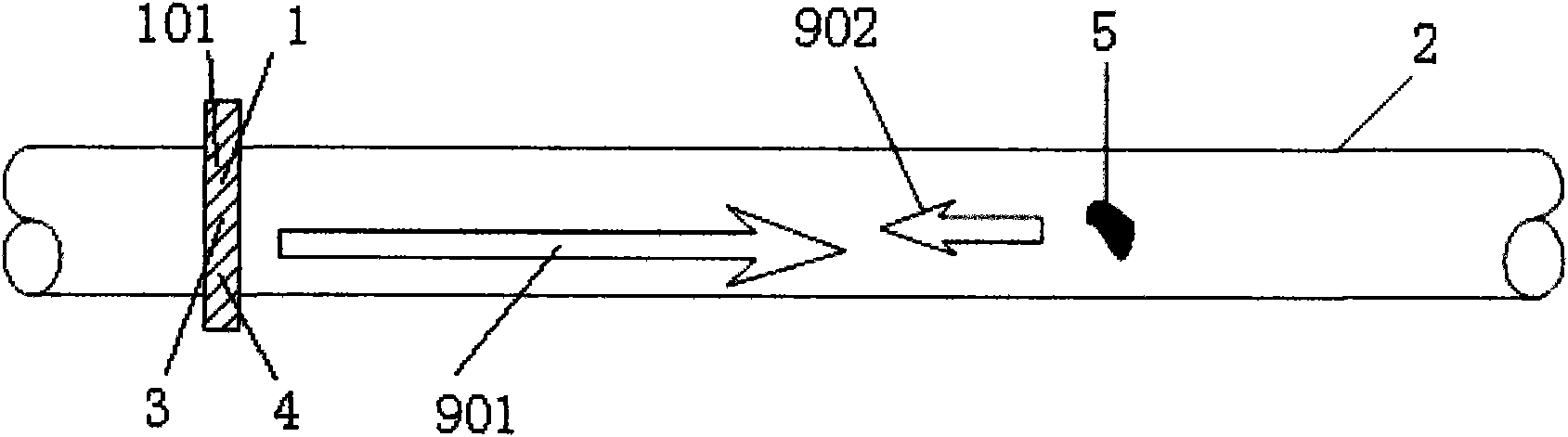

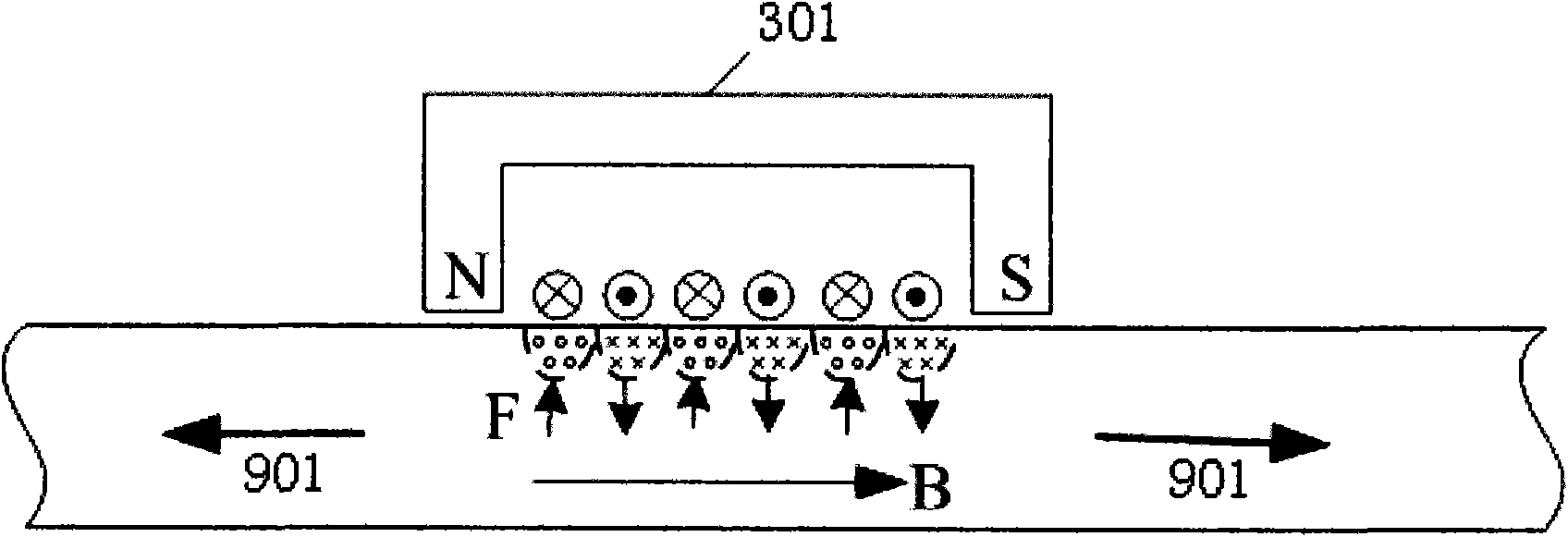

[0049] Embodiment 1 (with reference to Figure 1~6 )

[0050] An ultrasonic guided wave composite non-destructive testing method, which uses ultrasonic guided waves to propagate in the object to be tested, and detects the object to be tested by detecting reflected echoes 902; the points that need to be emphasized are:

[0051] The method used to excite and generate ultrasonic guided waves is an electromagnetic excitation method; the electromagnetic excitation method used to excite ultrasonic guided waves is specifically a composite excitation of magnetostrictive excitation and electromagnetic ultrasonic excitation; it receives reflection The method of the echo 902 is specifically a method of detection using a piezoelectric device.

[0052] In the ultrasonic guided wave composite nondestructive testing method, the components used to excite the ultrasonic guided wave and the piezoelectric device used to receive the reflected echo 902 are separately arranged separately (such as ...

Embodiment 2

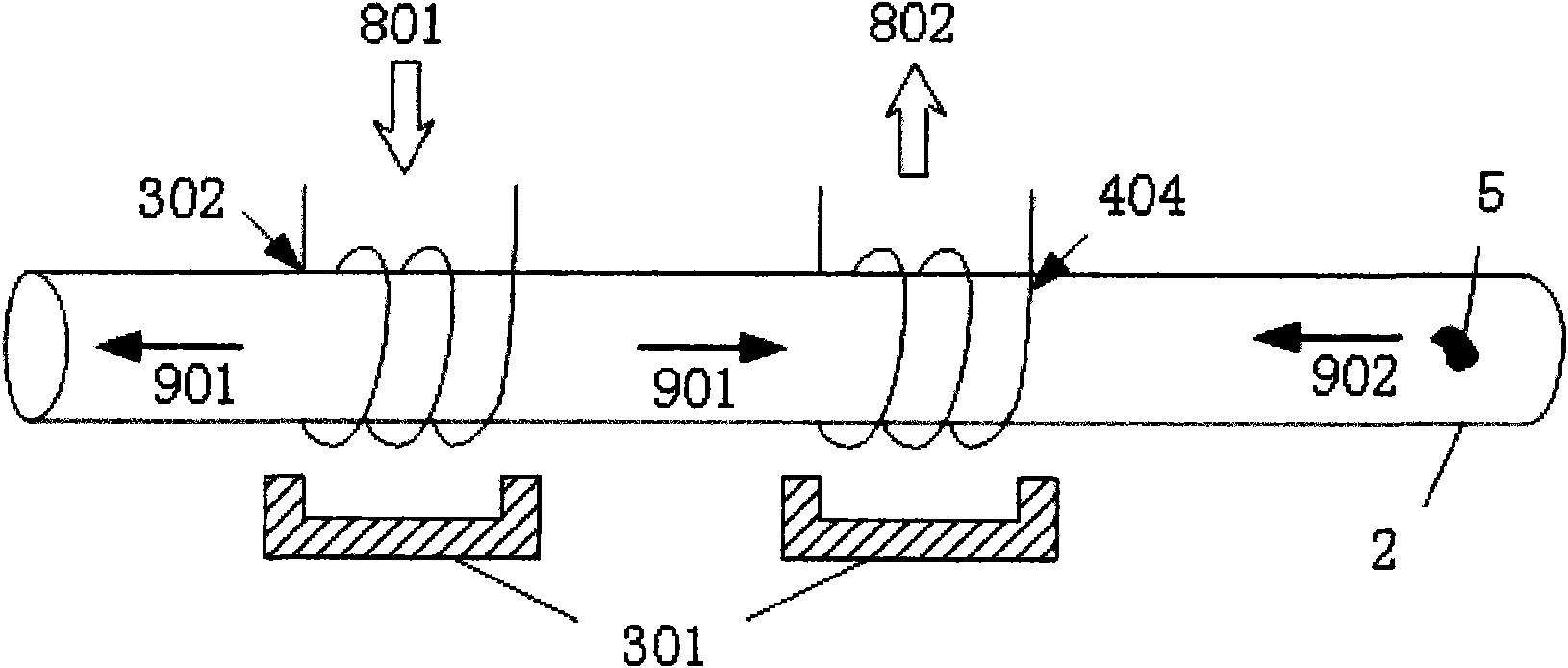

[0076] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0077] 1) The electromagnetic excitation method for exciting the ultrasonic guided wave is specifically one of the following two types: magnetostrictive excitation, electromagnetic ultrasonic (EMAT) excitation;

[0078] 2) In the ultrasonic guided wave composite non-destructive testing method, the components used to excite the ultrasonic guided wave and the piezoelectric device used to receive the reflected echo 902 are fixed together to form a As a whole, the whole is referred to as a detection probe ring 1 . The quality of the ultrasonic guided wave generated by electromagnetic excitation is high, and the piezoelectric device is used to detect the high sensitivity of vibration; the combination of these two characteristics can obtain better technical results.

[0079] 3) The electromagnetic excitation method can specifically use a single electromagnetic e...

Embodiment 3

[0087] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0088] 1) In the ultrasonic guided wave composite non-destructive testing method, the piezoelectric sensor receiving array 7 used includes 512 piezoelectric receiving units; these piezoelectric receiving units can be made into various specific array forms to facilitate more Good reception of reflected echo 902 signal.

[0089] 2) The detected component is a large-diameter oil and gas pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com