Ultrasonic detecting method for electric power pylon steel angle

A technology of ultrasonic guided wave and power tower, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., which can solve the problems of power tower collapse accidents, economic losses, corrosion, etc. Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

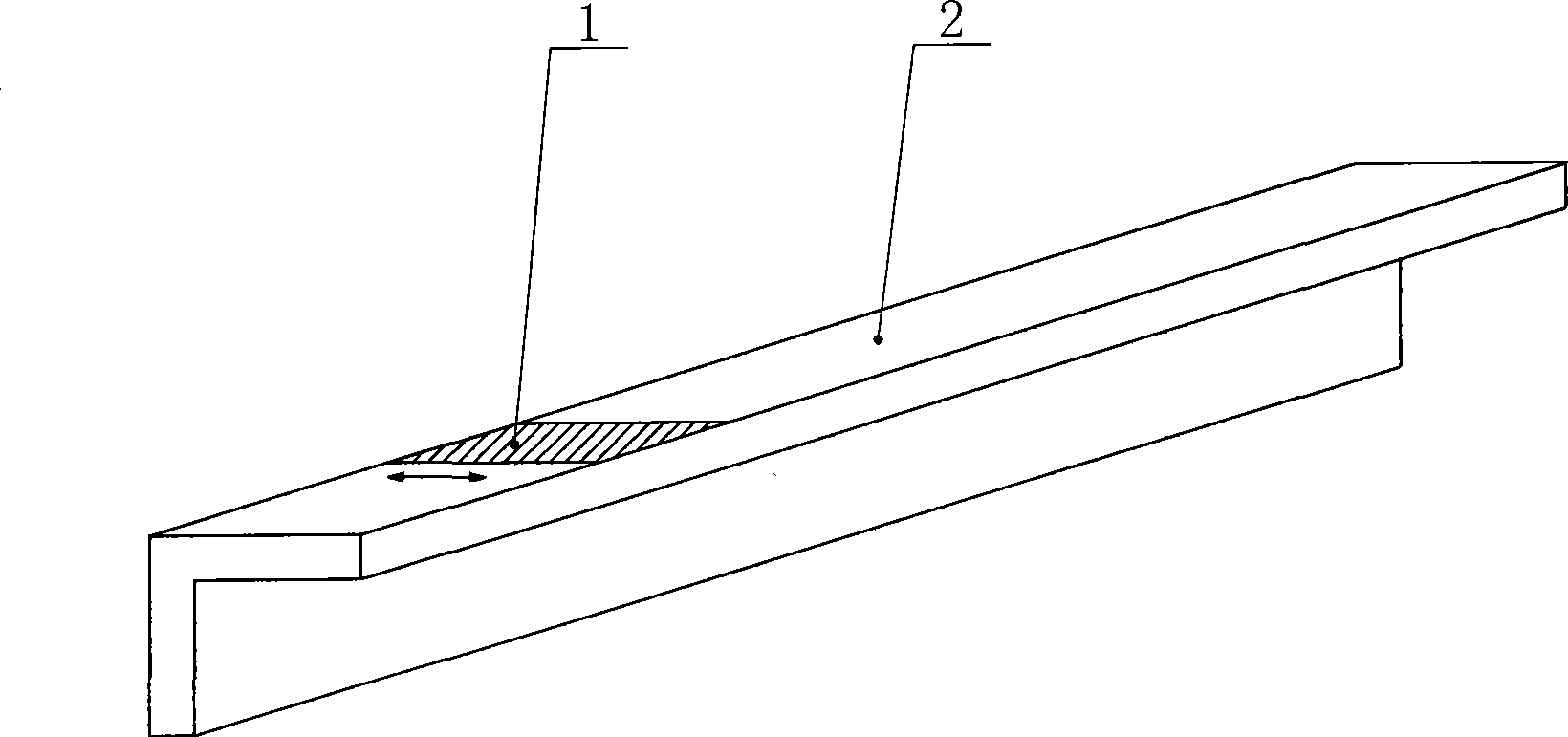

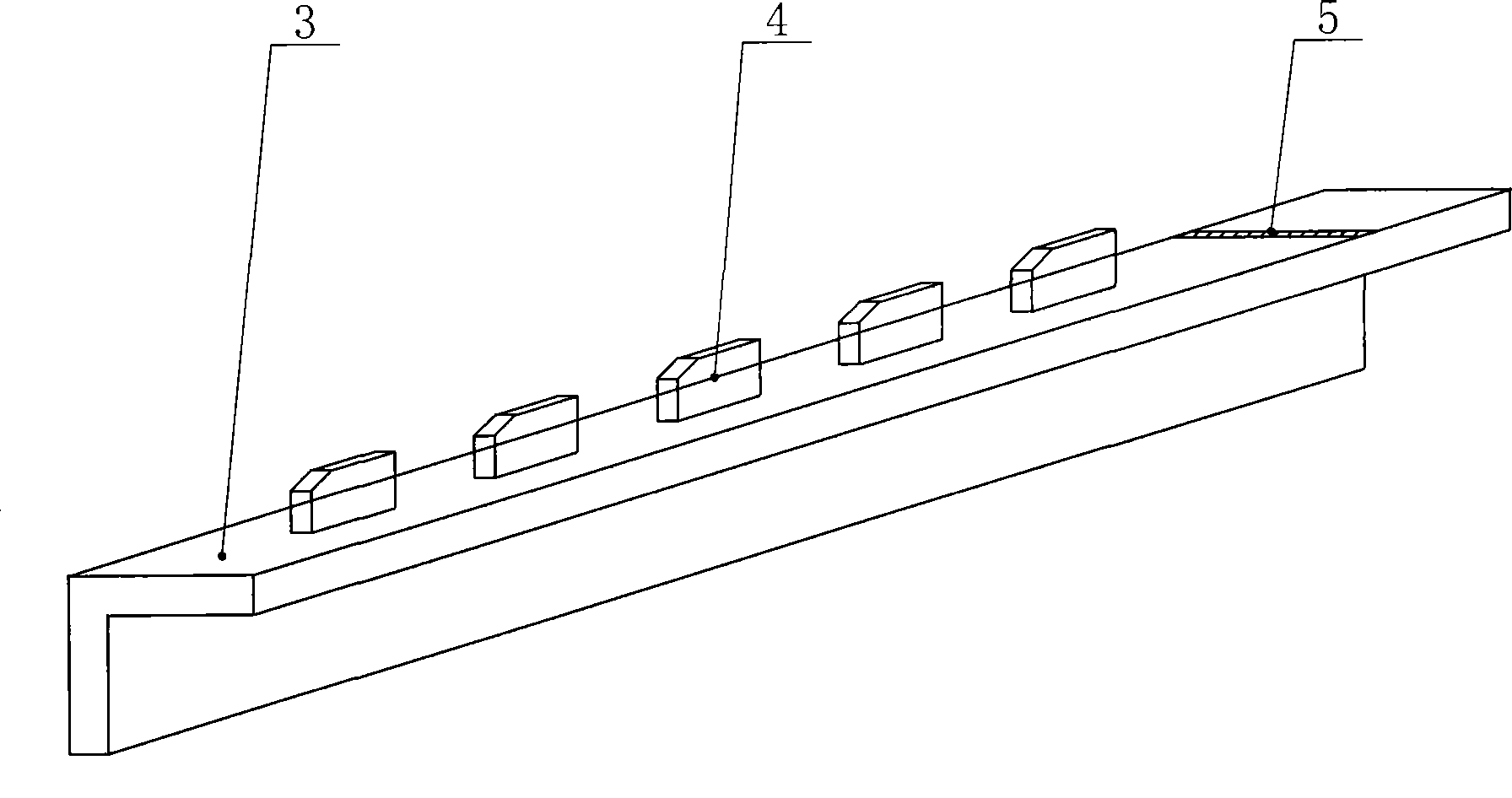

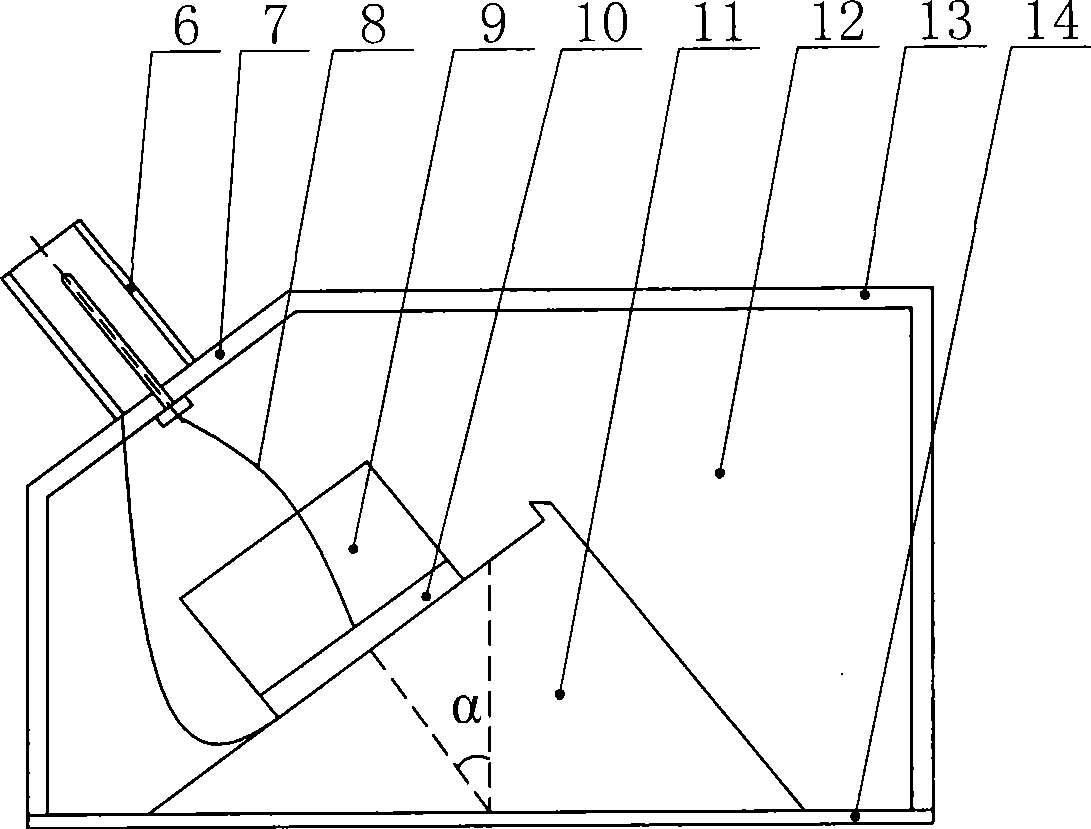

[0028] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] An ultrasonic guided wave detection method for the angle steel of a power tower mainly uses an ultrasonic flaw detector and an ultrasonic probe to detect the angle steel. The specific steps are as follows:

[0030] 1. Select an ultrasonic flaw detector: the excitation signal generated by it is a single-tone signal, preferably a wide-pulse narrow-band excitation signal, with a sensitivity margin ≥ 110dB, a sampling frequency ≥ 60MHz, a recordable waveform ≥ 100, and a display refresh frequency ≥ 60Hz , the sound velocity range is 1000-7000m / s; the ultrasonic flaw detector usually has a recordable function and a communication interface to exchange data and waveforms with the computer, and can also be connected to a printer to directly output the test results.

[0031] 2. Select the ultrasonic guided wave probe: the detection frequency is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com