Ultrasonic guided-wave detecting system for defect of composite insulator and detecting method of ultrasonic guided-wave detecting system

A technology of composite insulators and ultrasonic guided waves, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices. The effect of reducing the risk of missed inspection, high defect detection rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

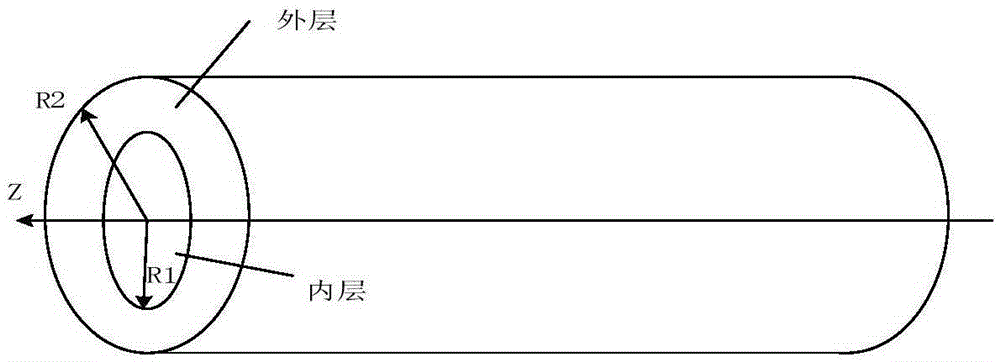

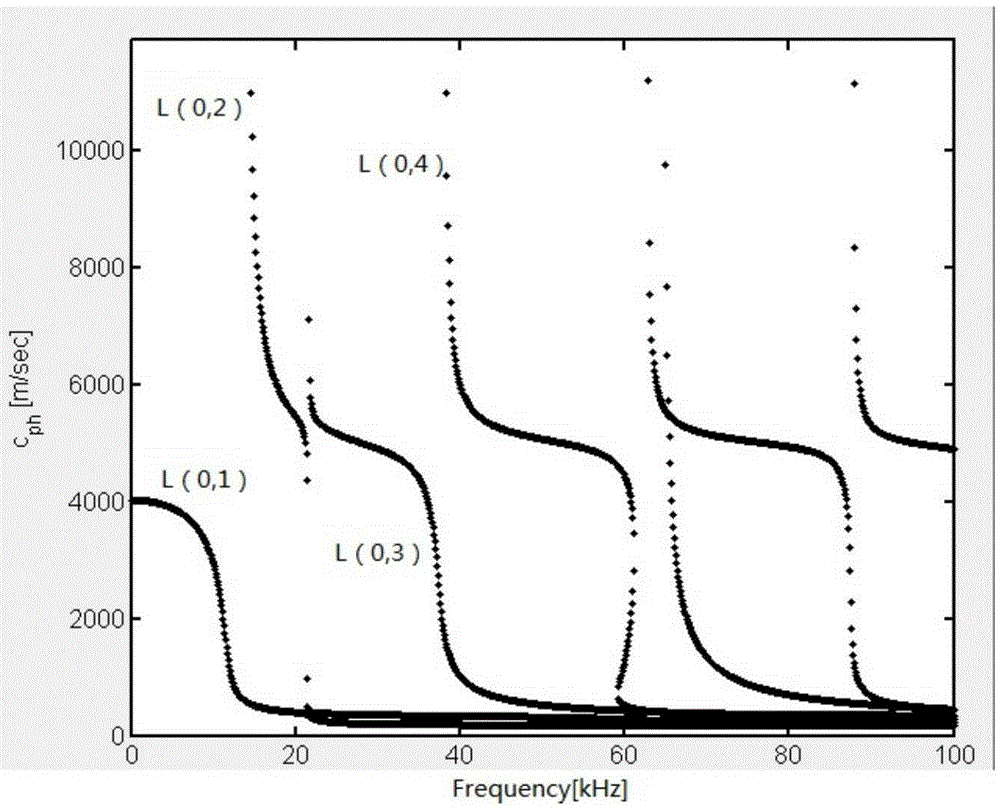

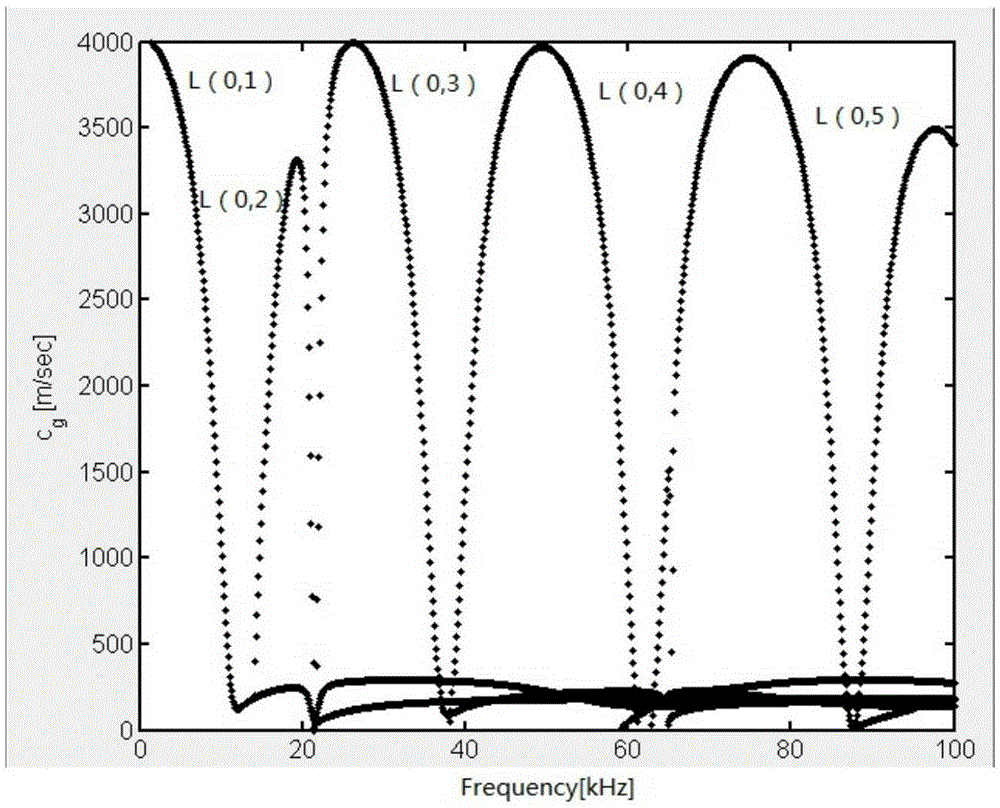

[0039] Such as figure 1Shown is a simplified double-layer rod model for theoretical analysis of composite insulators, where the coordinate axis z is the centerline of the cylinder, and R1 and R2 represent the radius at the interface and the outer radius of the outer layer, respectively. The experimental specimens in this example use the insulators produced by Guangzhou Microlean Electric Power Co., Ltd., the models are FXBW4-35 / 70, FXBW4-35 / 100 and FXBW4-110 / 100-A, obtained by measuring the data of the experimental specimens Relevant parameters, among which the technical parameters of the model FXBW4-110 / 100-A composite insulator are the length 1.06m (the length of the insulator is the length after cutting off the fittings at both ends), the radius of the glass core rod is 9mm, and the density is 2176.17kg / m 3 , Poisson's ratio 0.3, elastic modulus 57Gpa, outer silicone rubber coating thickness 4mm, density 1241.7kg / m 3 , Poisson's ratio 0.25, and elastic modulus 0.1245Gpa; u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com