Gas pipeline crack electromagnetical ultrasonic oblique wave guide detecting method

A natural gas pipeline, electromagnetic ultrasonic technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problem of not considering the influence of magnetostrictive effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

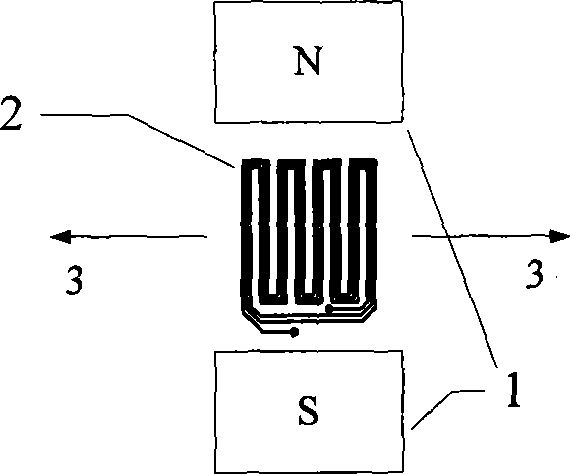

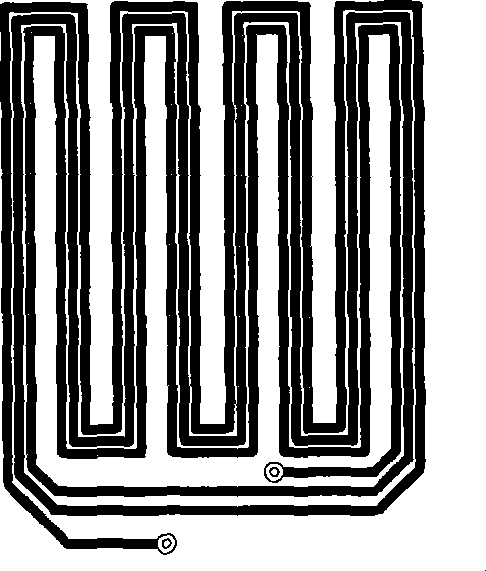

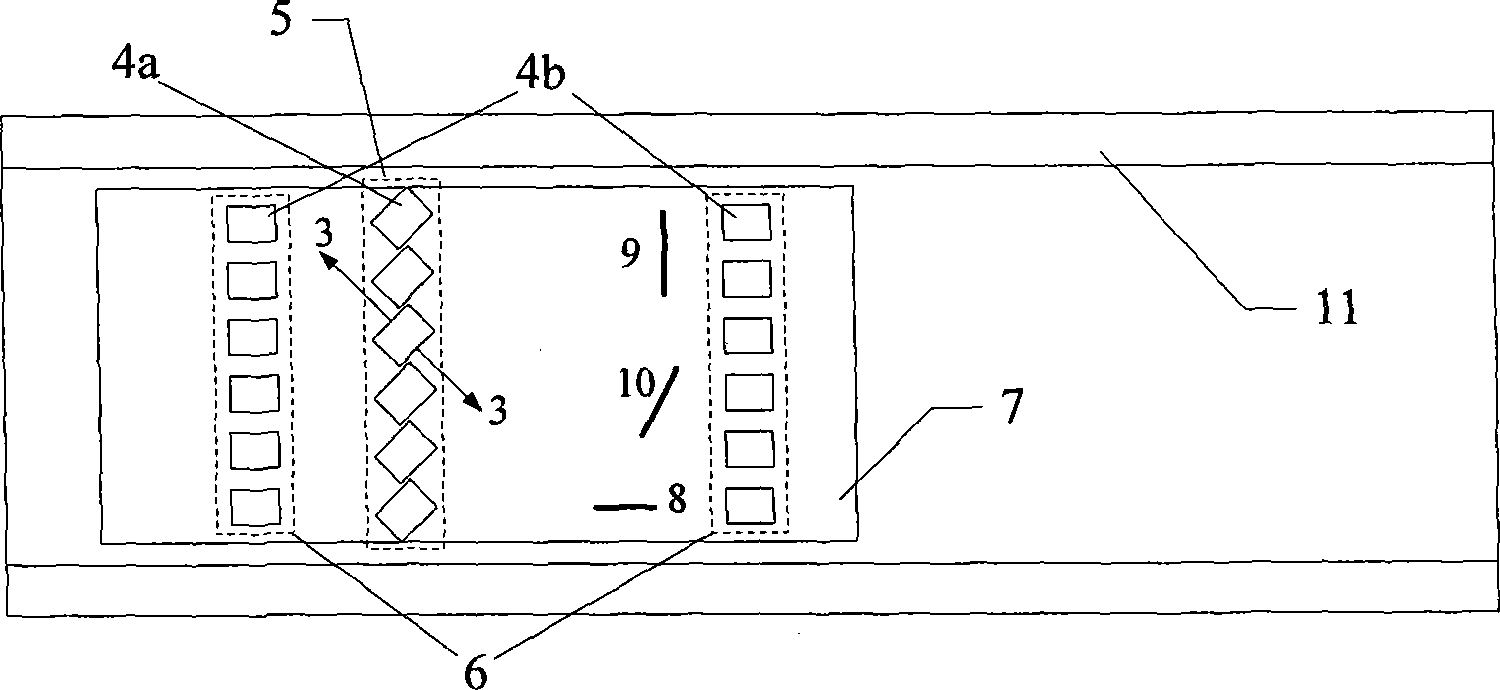

[0026] In the present invention, a printed circuit board-based three-split zigzag coil and an NdFeB permanent magnet block are used to form the attached figure 1 For the electromagnetic ultrasonic transducer unit shown, the cycle number of the three-split broken-line coil is 2 to 5. For the attached figure 2 In the specific form, the period number of the coil is 3.5. The constant bias magnetic field provided by the permanent magnet is in the range of 1~1.5T, the typical value is 1T. Its direction is parallel to the wire direction of the broken line coil and is located inside the pipe wall. This configuration determines the bias magnetic field and The alternating eddy currents induced by the coil are parallel, so there is no Lorentz force effect, that is, no ultrasonic waves will be generated in non-ferromagnetic conductive materials. For the natural gas pipeline wall constructed of ferromagnetic steel material, this arrangement will generate shear ultrasonic waves under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com