Damage detection method based on instantaneous phase changing degree

An instantaneous phase and damage detection technology, which is applied in the processing of detection response signals, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem of inability to effectively eliminate noise, detection wave signal noise interference, and inability to correctly evaluate damage scattering Wave signal ToF and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

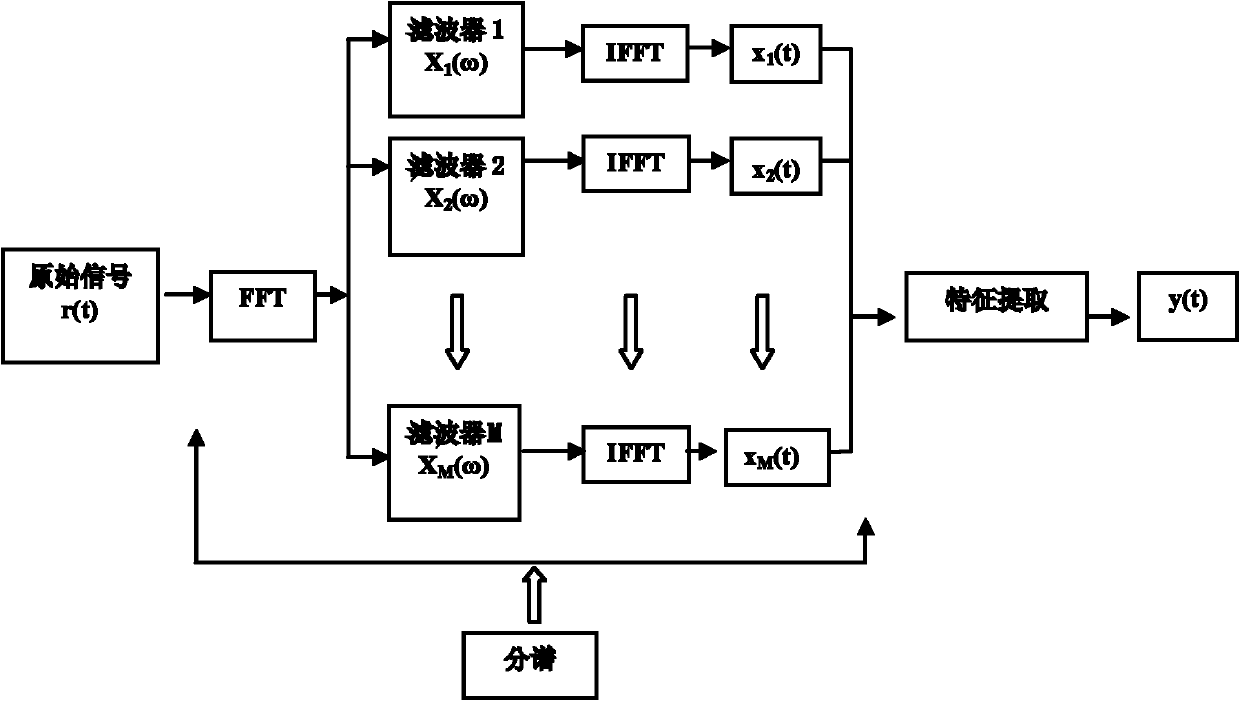

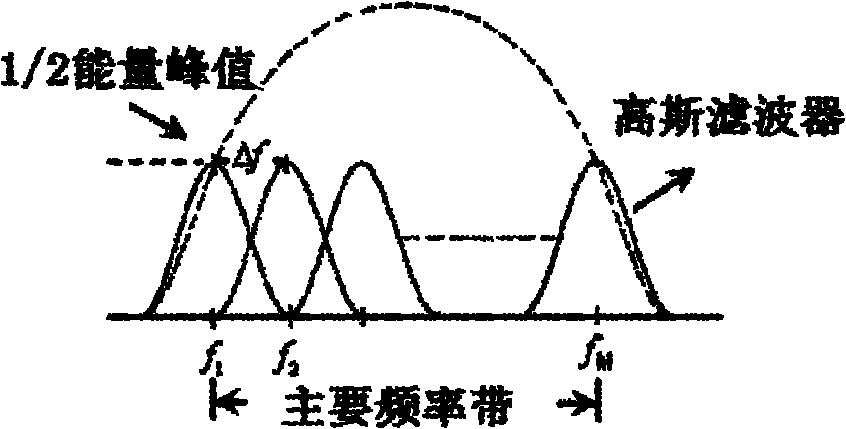

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

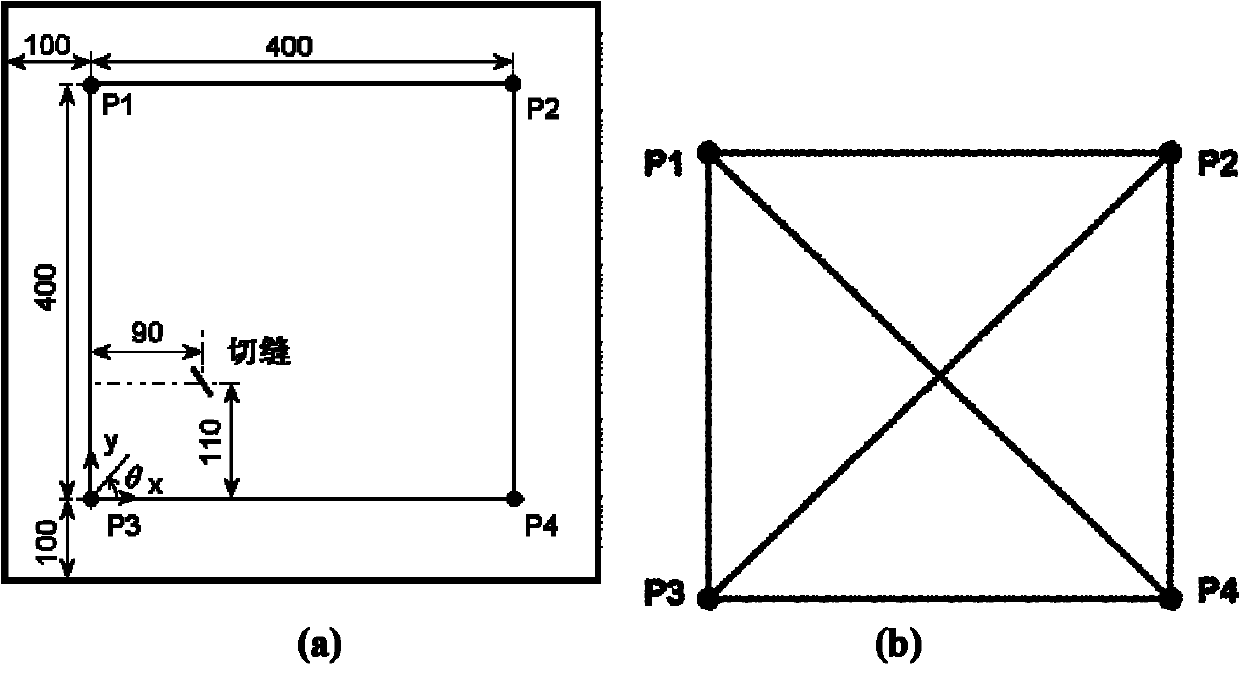

[0038] In the embodiment, a 5-cycle sinusoidal AM pulse modulated by a Hanning window with a center frequency of 300 kHz is used as an excitation signal to excite Lamb waves. The acquisition time of each signal was set to 200 μs. Four circular piezoelectric strain gauges are fixed on the surface of an aluminum plate (600mm×600mm×2.0mm), enclosing a detection area of 400mm×400mm, such as image 3 (a) shown. The selected sensing paths of the six excitation-induction wave signals adopt the working mode of "one sending and one receiving" to excite and collect Lamb wave signals, covering the detection area, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com