Ultrasonic guided wave detection technology for positioning defects of composite laminated plate

A technology of composite material layer and ultrasonic guided wave, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, positioning, radio wave measurement system, etc., to improve positioning reliability and reduce error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings.

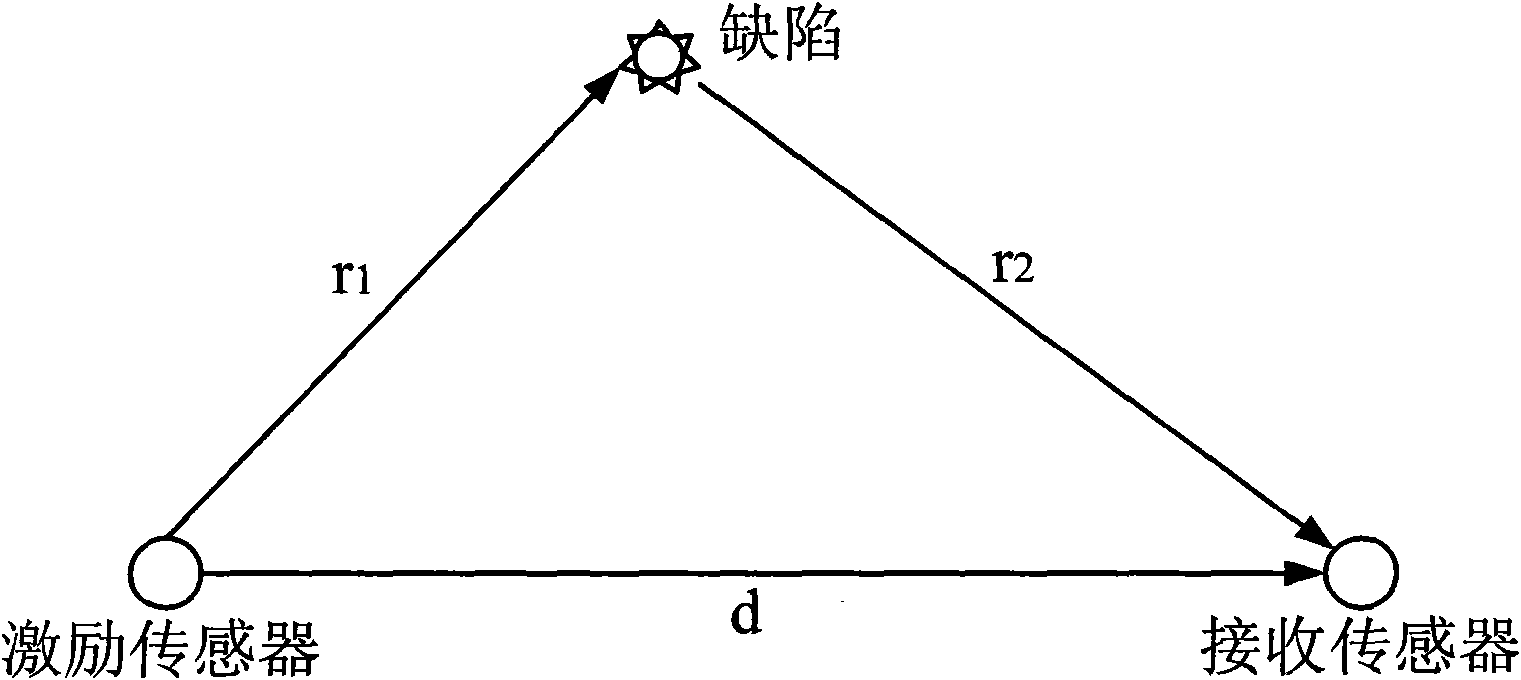

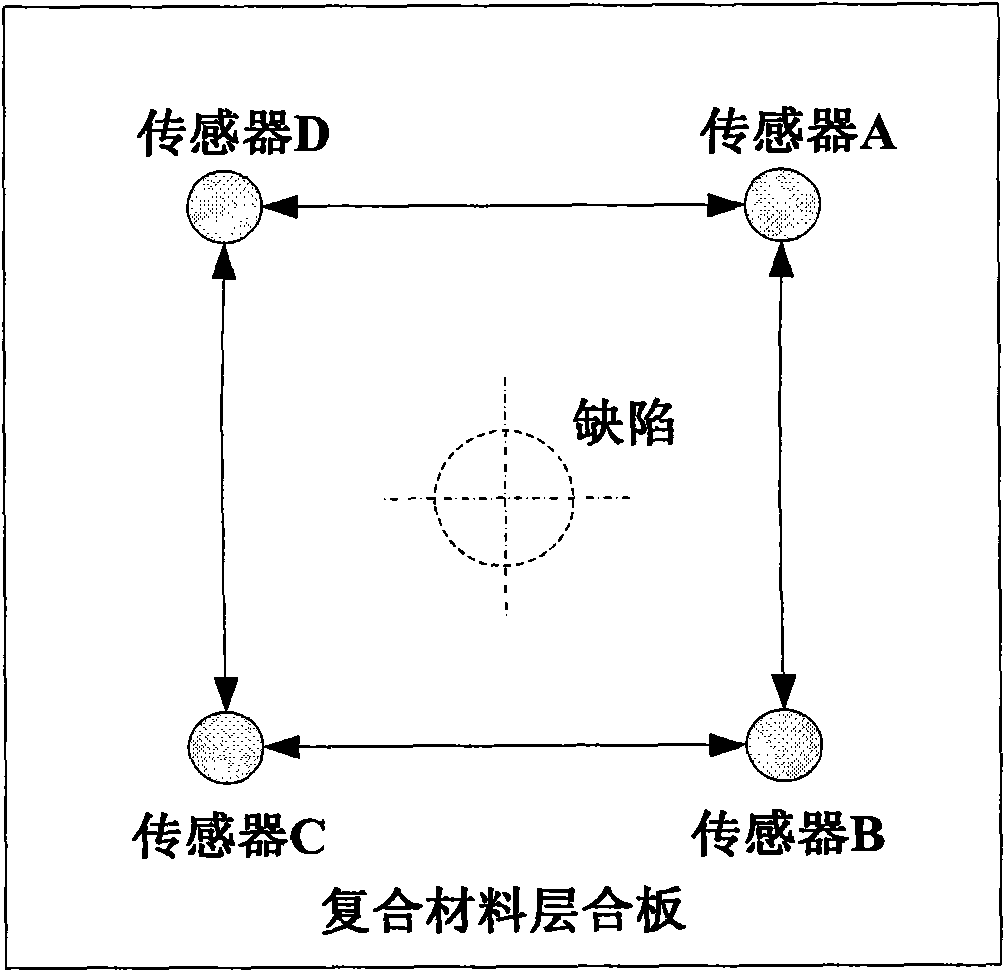

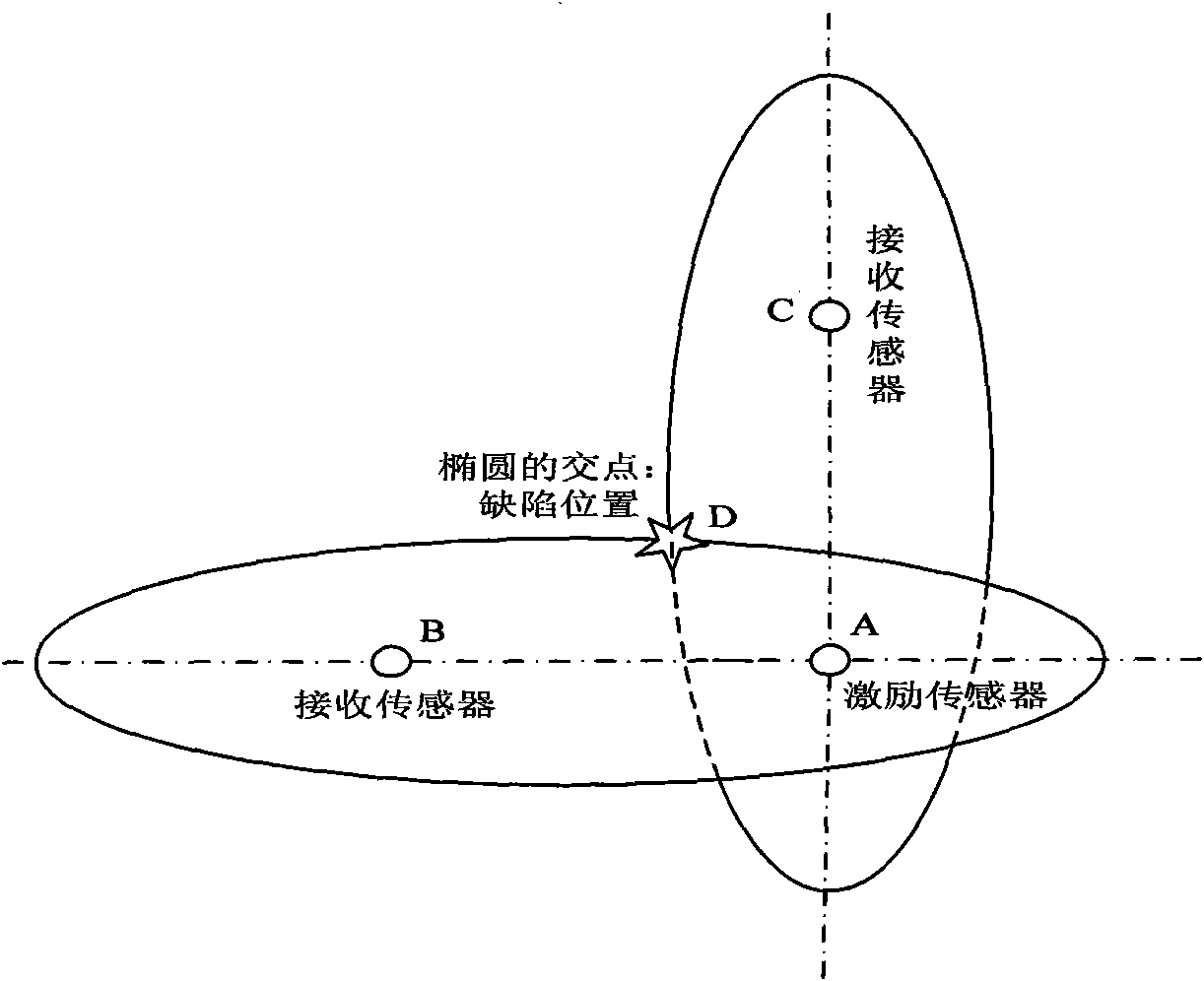

[0012] In order to accurately locate the two-dimensional defects in the structure, the propagation path of the guided wave must first be analyzed. The guided waves emitted by the excitation sensor propagate in the board, and all the guided waves can reach the receiving sensor through many different paths. Such as figure 1 It is shown that in the research of defect location, the signal that reaches the receiving sensor through defect reflection contains defect information, while the signal that does not reach the receiving sensor through defect reflection does not contain defect information and is useless for defect location, so it can be regarded as public. Information to be removed. The algebraic difference of the guided wave signals obtained before and after the defect in the structure can be used to obtain the difference signal. The difference sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com