Intermittent feeding mechanism for bowl blanks

A technology of feeding mechanism and bowl blank, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low degree of automation, large damage of bowl blank, shortening production time of daily ceramics, etc., and achieve high degree of automation and versatility Good, high positioning efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

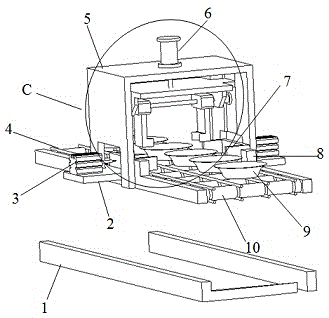

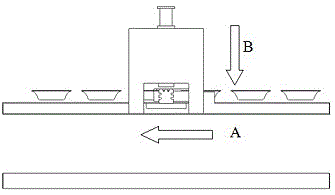

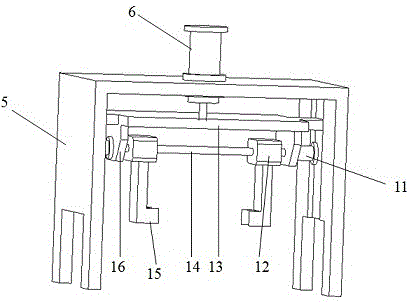

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] control figure 1 —3. Before the device works, the piston rod of the positioning cylinder 3 is retracted, the baffle plate 7 is located on both sides of the transmission bracket 1, and the retraction of the piston rod of the lifting cylinder 6 also makes the slide plate 13 at the upper end of the main bracket 5, and the screw motor 11 The screw rod 14 is driven to rotate, and the screw rod 14 drives the slide block 12 on it to move in reverse together with the clamping handle 15, and the device is in a ready state.

[0016] After the device is started, a bowl blank 9 flows into the conveyor belt 4 from the previous process of bowl blank 9 production, and the conveyor belt 4 moves the bowl blank 9 to the direction of the main support 5. When the bowl blank 9 moves below the main support 5, the position The sensor 8 detects the bowl blank 9, at this time the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com