Blind hole measurement method for value and distribution of residual stress of thick-wall and large-diameter welded steel pipe

A technology of welding steel pipes and residual stress, applied in the direction of measuring force, measuring devices, instruments, etc., can solve problems such as inability to reflect, and achieve the effect of scientific residual stress level and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The purpose of the present invention is achieved through the following technical requirements and measures:

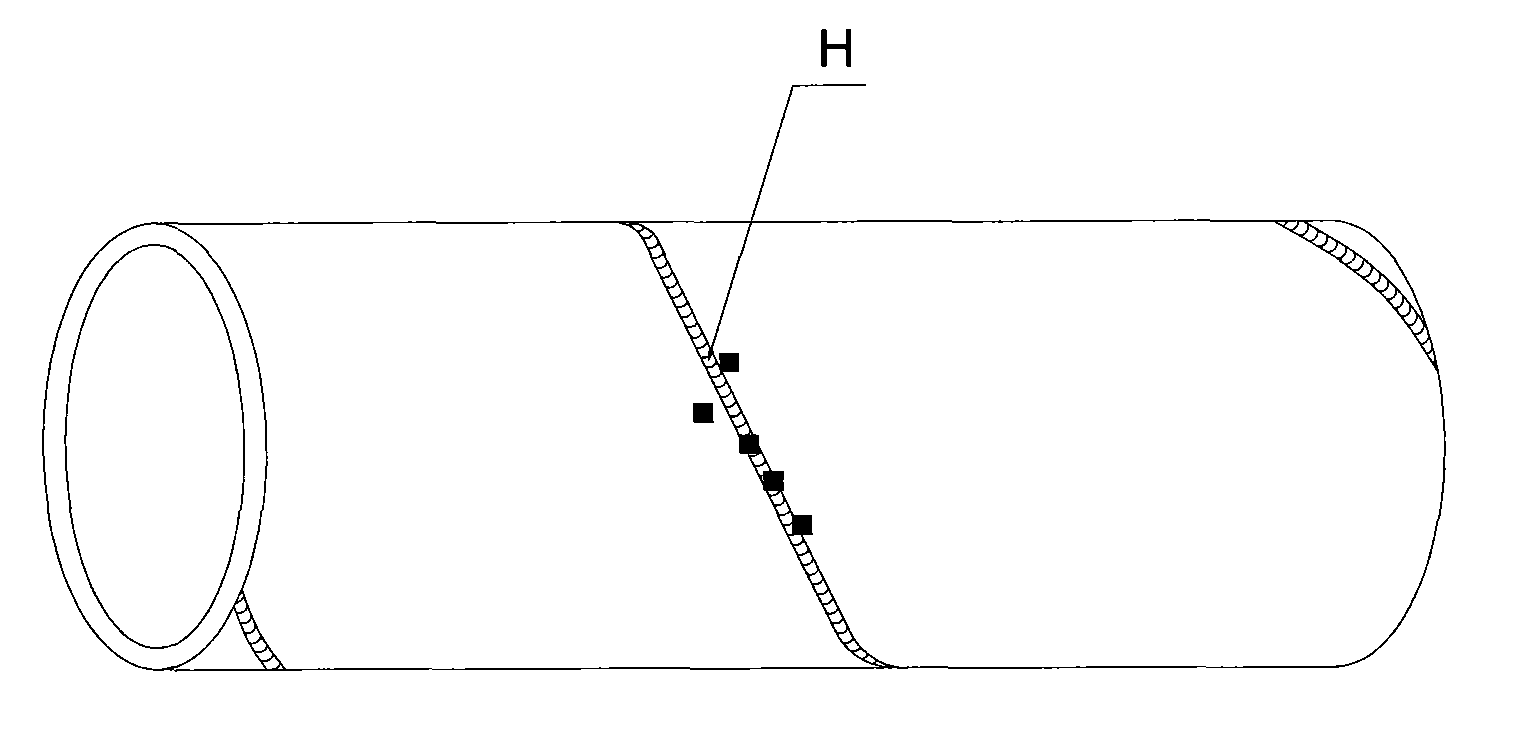

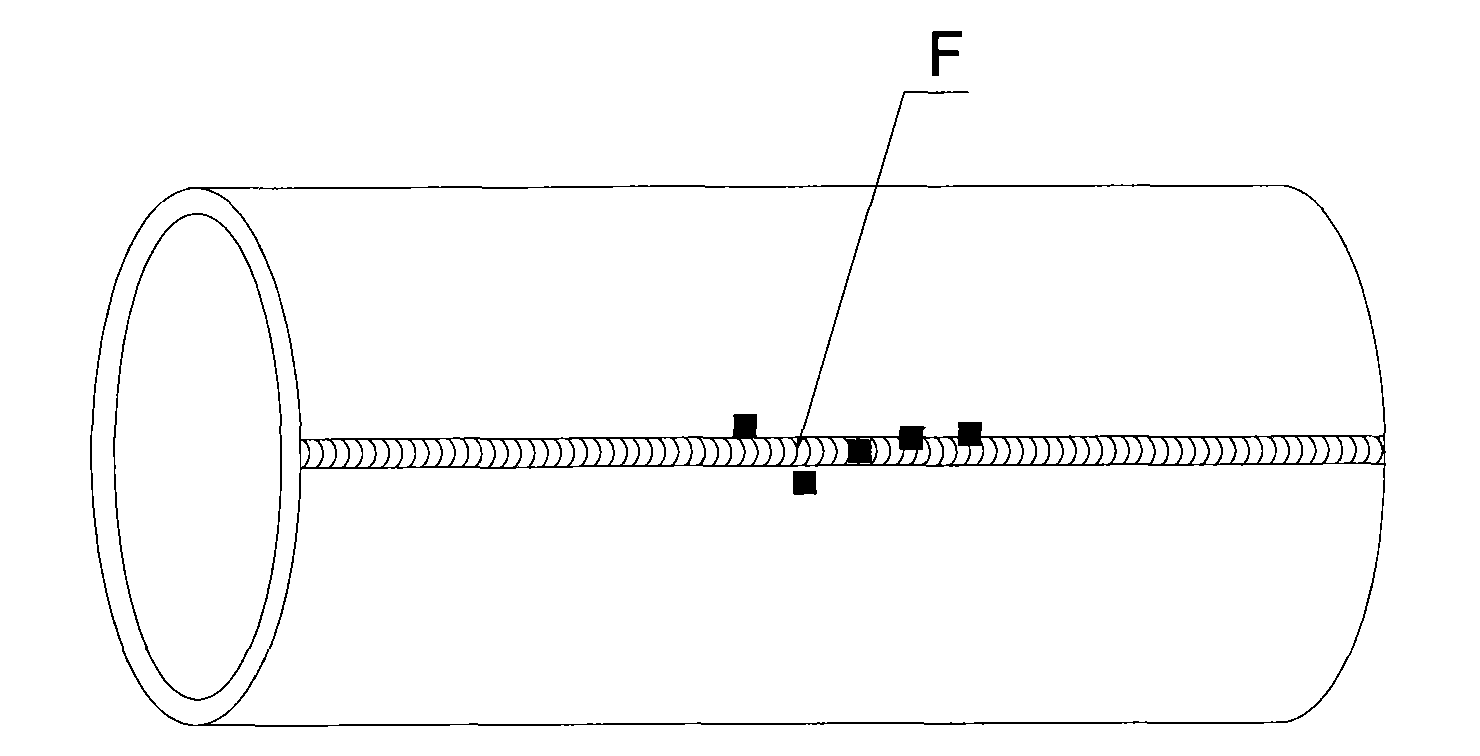

[0025] (1) Applicable pipe type: spiral submerged arc welded steel pipe; UOE formed welded steel pipe and JCOE formed welded steel pipe. (referred to as spiral tube, UOE tube, JCOE tube, the same below)

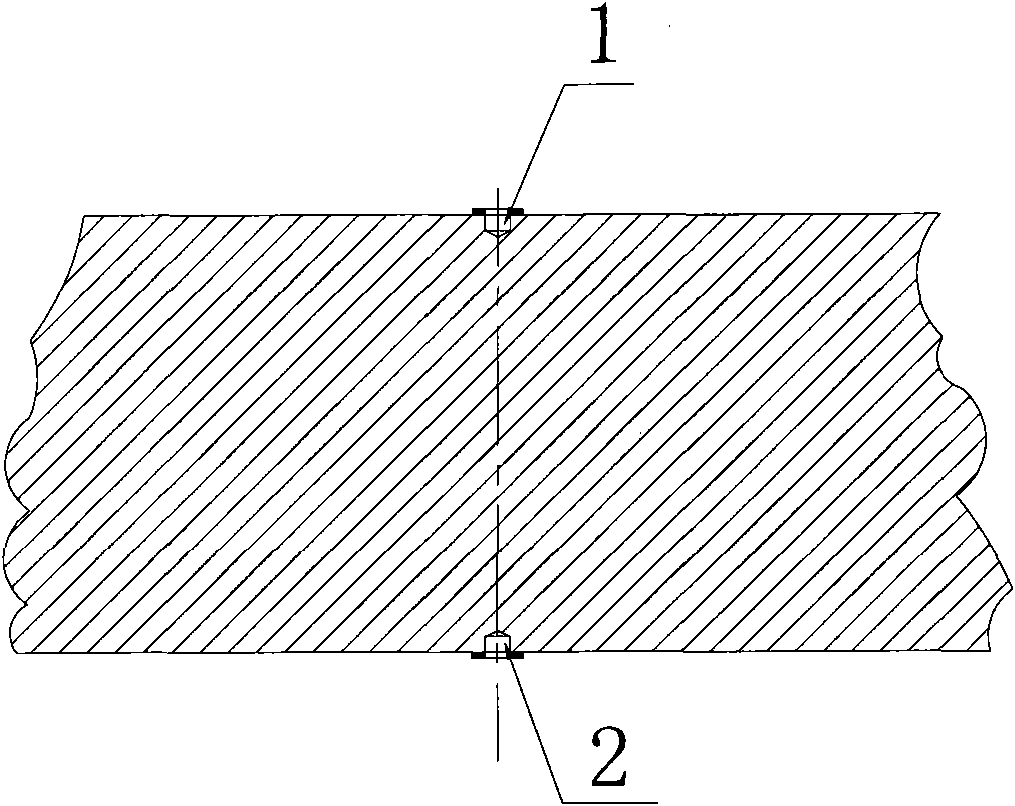

[0026] (2) Applicable pipe body size specifications: diameter ≥ 600mm, wall thickness ≥ 12mm. The diameter dimension is used to ensure the space for operating and arranging measuring points in the pipe; the wall thickness dimension ensures that the measured values of the inner and outer wall measuring points are not interfered and affected by each other.

[0027] (3) Measuring the interception length of the pipe body: the length of the measuring pipe section of UOE and JCOE formed welded steel pipe is 2.5 times the diameter of the pipe body; the length of the measuring pipe section of the spiral submerged arc welded steel pipe is 2 complete spiral weld pitch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com