High-strength high-ductility X70 thick-wall seamless pipeline steel and manufacturing method

A seamless pipeline steel, high-strength and high-toughness technology, used in manufacturing tools, furnace types, furnaces, etc., can solve the problems of poor impact performance, inconsistent performance, limited cooling capacity, etc., and achieve good low-temperature impact performance and overall pipe body. The effect of uniform organization and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

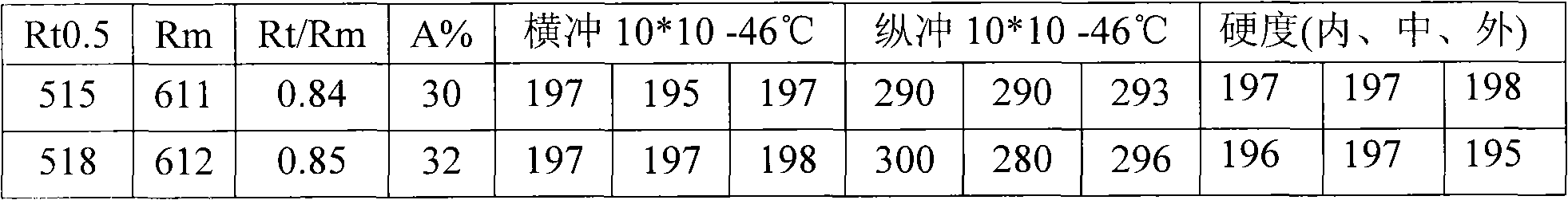

Examples

Embodiment Construction

[0008] The high-strength and high-toughness X70 thick-wall seamless pipeline steel and the manufacturing method of the present invention will be described in combination with examples.

[0009] In the high-strength and high-toughness X70 thick-walled seamless pipeline steel of the present invention, the weight ratio of steel constituent elements is C: 0.04-0.12%, Si: 0.17-0.35%, Mn: 1.20-1.60%, P≤0.015%, S ≤0.010%, Mo: 0.10~0.30%, Al: 0.005~0.045%, Nb: 0.02~0.06%, V: 0.02~0.10%, Cu: 0.10~0.25%, Ni: 0.10~0.30%, Ti: 0.010~ 0.030%, Cr: ≤ 0.20%), CE ≤ 0.43, Pcm ≤ 0.22, the rest is iron, traces of impurity elements.

[0010] The reasons for selecting the main components are as follows:

[0011] Carbon: It is a traditional strengthening element, which has the advantages of low cost and good regulation sensitivity. However, high content also has the disadvantage of negatively affecting the welding performance, mechanical properties and hydrogen-induced cracking (HIC) resistance of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com