Combustion equipment and burner combustion method

a combustion method and combustion equipment technology, applied in combustion types, combustion methods, combustion using lumps and pulverulent fuels, etc., can solve the problems of limit to reducing nox emissions and unstable flames, and achieve the effect of reducing nox emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

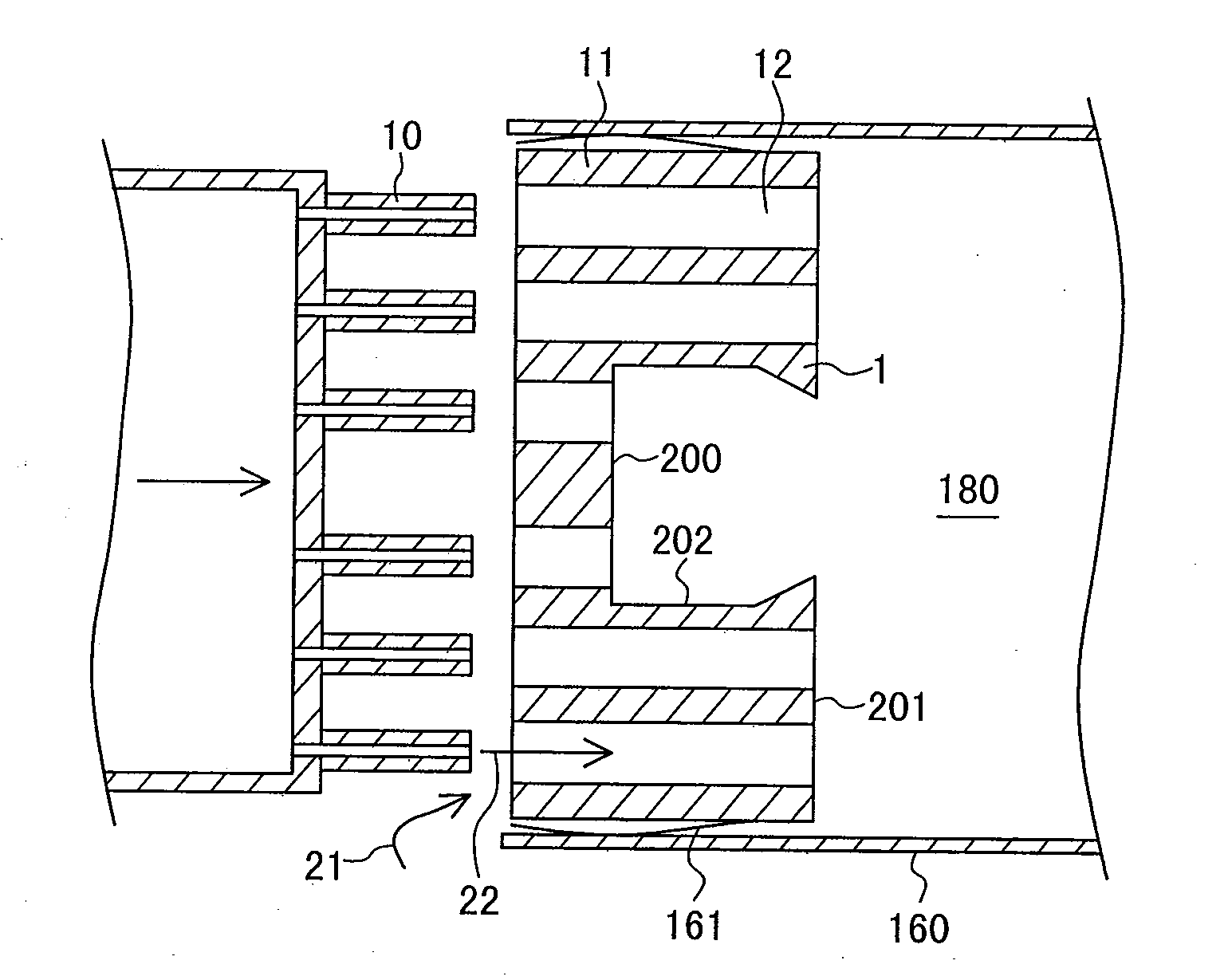

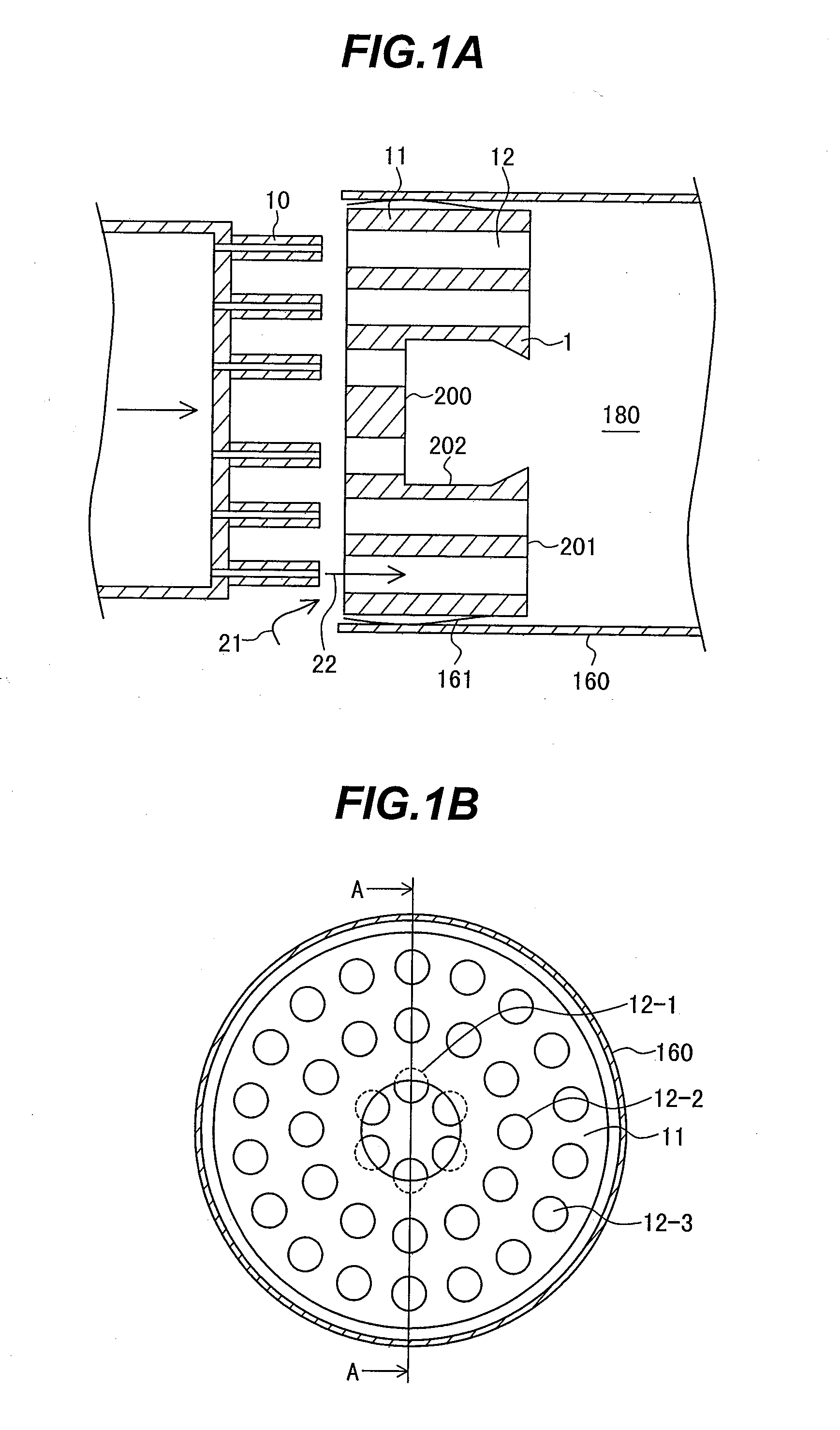

[0058]FIG. 1B is a front view of a burner plate 11 as viewed from a combustion chamber 180. FIG. 1A is an enlarged schematic cross-sectional view taken along line A-A of FIG. 1B, illustrating fuel nozzles 10, air holes 12 and their peripheral portions in the entire gas turbine schematically shown in FIG. 11.

[0059]A burner of the first embodiment includes the fuel nozzles 10; the burner plate 11 having the air holes 12; a protrusion 1 formed on the burner plate 11; and a liner 160 defining the combustion chamber 180. A spring seal 161 is provided between the burner plate 11 and the liner 160.

[0060]Fuel flow 22 is jetted from the fuel nozzle 10 toward the inlet portion of the air hole 12. Air flow 21 enters the inlet portion of the air hole 12 from the outer circumferential side of the fuel nozzle 10. The air flow 21 having entered the air holes 12 passes through the inside of the air hole 12 so as to encircle the fuel flow 22 from the outer circumferential side thereof, and jet out f...

embodiment 2

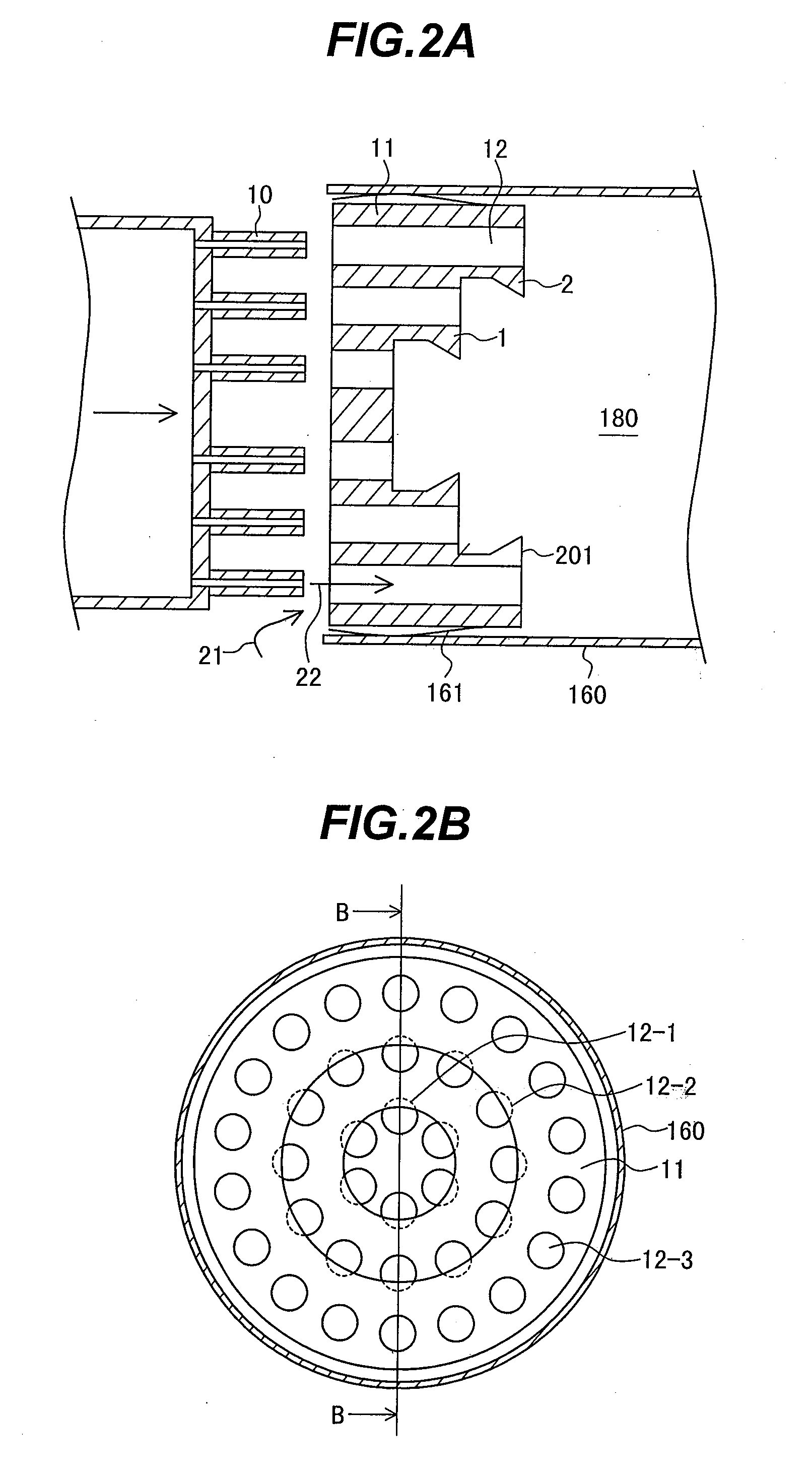

[0078]FIG. 2B is a front view illustrating a burner plate 11 as viewed from a combustion chamber 180. FIG. 2A is an enlarged schematic cross-sectional view illustrating fuel nozzles 10, air holes 12 and their peripheral portions in the entire gas turbine of FIG. 11, taken along line B-B of FIG. 2B.

[0079]In the first embodiment, the flames formed by the first circular row air holes 12-1 are stabilized to thereby improve the stability of the flames formed by the second and third circular row air holes 12-2, 12-3. In contrast to this, in a second embodiment, a protrusion 2 is provided for also the second circular row air holes 12-2 to improve the stability of the flames formed by the second circular row air holes 12-2. Consequently, the flame stability of the entire burner can be further enhanced.

[0080]The basic mechanism of the flame stability improvement is similar to the contents described with FIG. 7. Specifically, high-temperature recirculation flow is formed not only on the burne...

embodiment 3

[0084]FIG. 3B is a front view illustrating a burner plate 11 as viewed from a combustion chamber 180. FIG. 3A is an enlarged schematic cross-sectional view illustrating fuel nozzles 10, air holes 12 and their peripheral portions in the entire gas turbine, taken along line C-C of FIG. 3B. FIG. 12 illustrates a shape of the air hole 12.

[0085]The burner plate 11 in a third embodiment is shaped such that a circular cone is hollowed out. In other words, a plane of the burner plate 11 at which an outlet portion 301 of the air hole 12 is located is shaped to open toward the combustion chamber as shown in FIG. 12. Specifically, the plane formed by the outlet portion 301 of the air hole 12 is inclined with respect to the central axis of the burner.

[0086]An obstacle is provided on the downstream side of the outlet portion 301 of the air hole 12 so as to disturb fuel flow and air flow. This obstacle corresponds to the protrusion 1, which is formed annular and provided for each circular row air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com