Repatching method for top liner of blast furnace hot-wind pipeline

A technology of hot air pipes and pipes, which is applied to blast furnace parts, blast furnaces, and details of blast furnaces to achieve the effects of restoring production, shortening repair time, and improving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

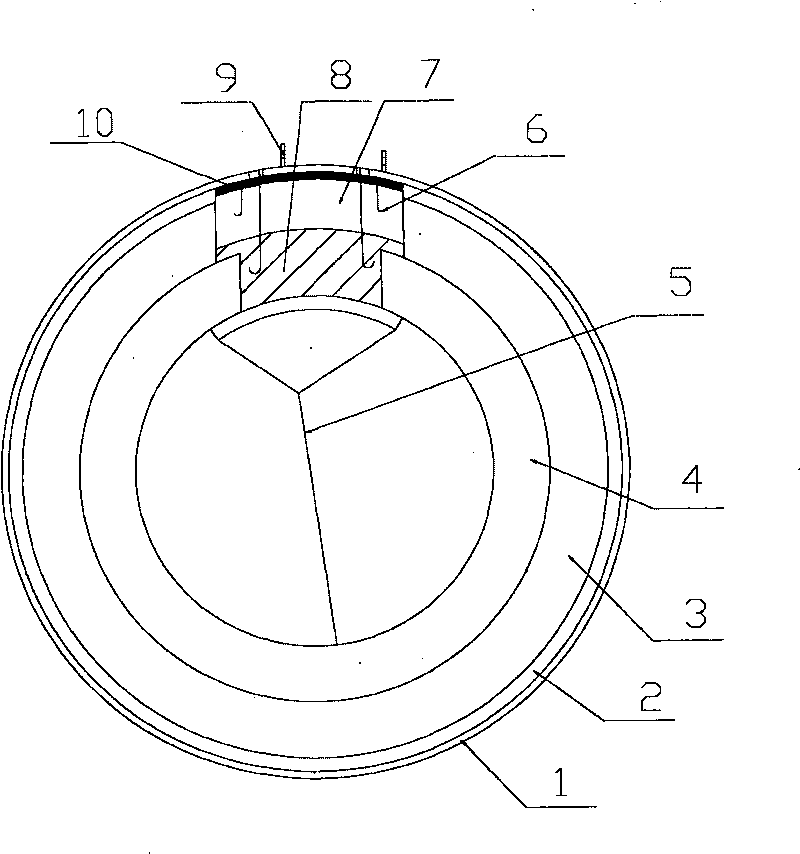

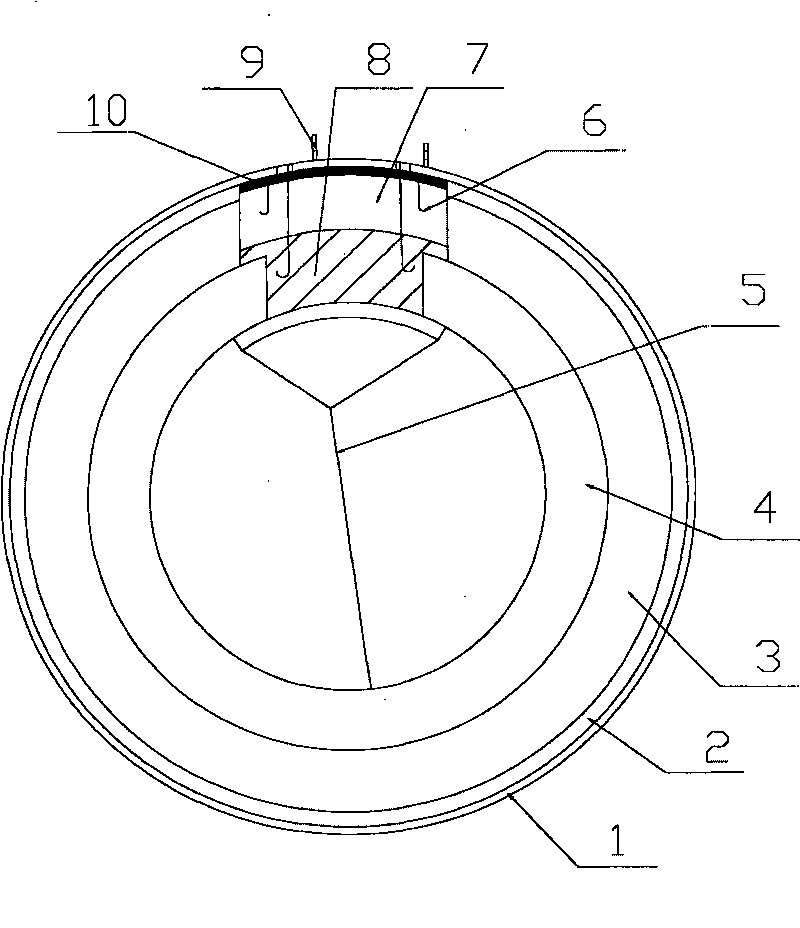

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] exist figure 1 In the process, first determine the damage of the low-creep andalusite brick 4 of the working layer on the top of the hot air duct and the high-alumina lightweight brick and clay lightweight brick 3 of the insulation layer. For the serious damage of the hot air duct, generally choose to cool the hot air duct first , and then go inside to check for damage.

[0024] The second step is to open a hole in the steel shell 1 of the hot air duct according to the damage of the lining. The size of the hole should be 80mm or 100mm smaller than the size of the intact working layer brick 4 on each side. The clay spray paint 2 around the hole should be cleaned to facilitate welding. Stainless steel hooks; when cleaning the damaged inner lining on the top, it is necessary to determine whether to provide necessary fixed support for the adja...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com