Triangular flexible large pull rod device with hot air pipelines

A technology of hot air pipes and large tie rods, which is applied to blast furnace parts, furnaces, heating furnaces, etc., to achieve the effect of increasing rigidity and improving the stress-bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

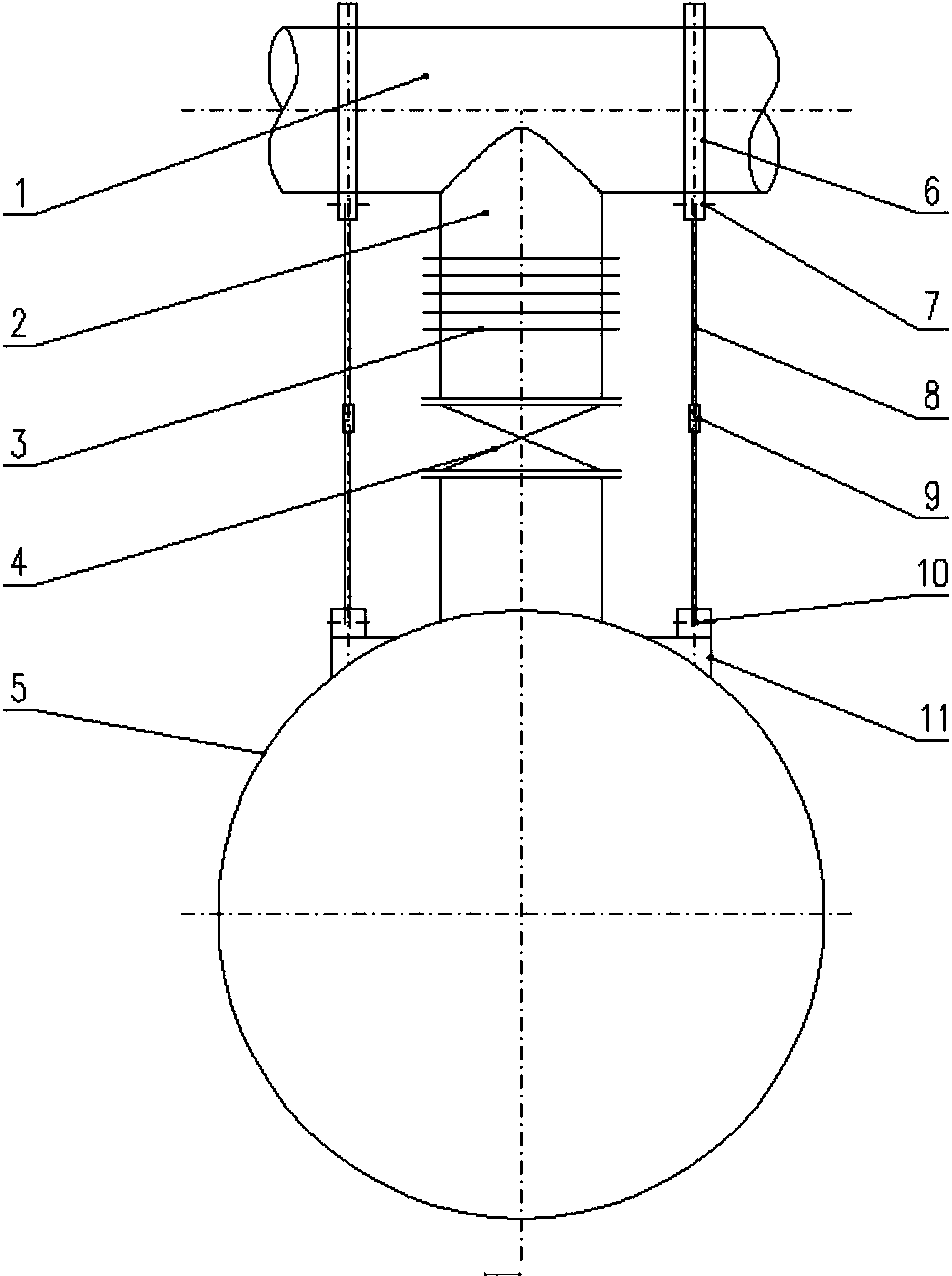

[0030] image 3 It is a specific embodiment of the present invention.

[0031] Depend on image 3 It can be seen that the present invention includes: hot blast main pipe 1, hot blast branch pipe 2, hot blast branch pipe compensator 3, hot blast valve 4, hot blast stove shell 5, hot blast pipe upper tie rod support 12, flexible large tie rod 13, connecting plate 14, hot blast stove Furnace shell reinforcement ring 15.

[0032] A large tie rod support 12 is arranged at the fork where the hot blast main pipe 1 is connected with the hot blast branch pipe 2 . A reinforcing ring 15 is set on the hot blast stove shell 5, and a connecting plate 14 is set on the reinforcing ring 15 for convenience of connection. The large flexible pull rod 13 is used to connect the pull rod support 12 and the connecting plate 14, and the reinforcing ring 15 is a complete 360° circular ring. Thereby, an integral tie rod combination device can be formed to ensure the safety and stability of the hot a...

Embodiment 2

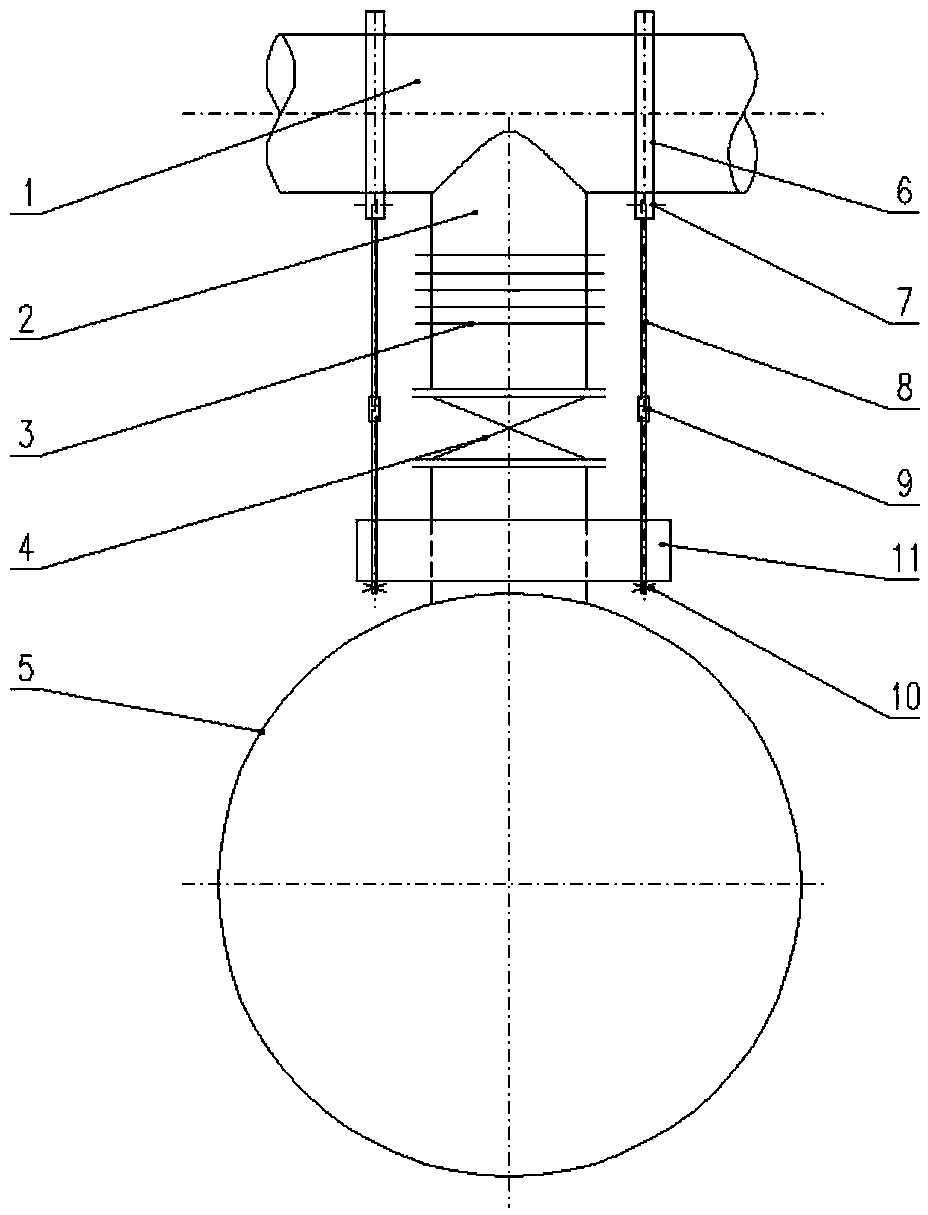

[0034] Figure 4 It is another specific embodiment of the present invention.

[0035] Depend on Figure 4 It can be seen that this embodiment includes: hot blast main pipe 1, hot blast branch pipe 2, hot blast branch pipe compensator 3, hot blast valve 4, hot blast furnace shell 5, hot blast pipe upper tie rod support 12, flexible large tie rod 13, connecting plate 14, hot blast Furnace shell reinforcement ring 15.

[0036] In this example, the method is the same as image 3 Similarly, the difference is that the tie rod supports 12 corresponding to the two groups of large tie rods can be combined into one set according to the actual arrangement.

[0037] A large tie rod support 12 is arranged at the fork where the hot blast main pipe 1 is connected with the hot blast branch pipe 2 . A reinforcing ring 15 is set on the hot blast stove shell, and a connecting plate 14 is set on the reinforcing ring 15 for convenience of connection. The large flexible pull rod 13 is used to ...

Embodiment 3

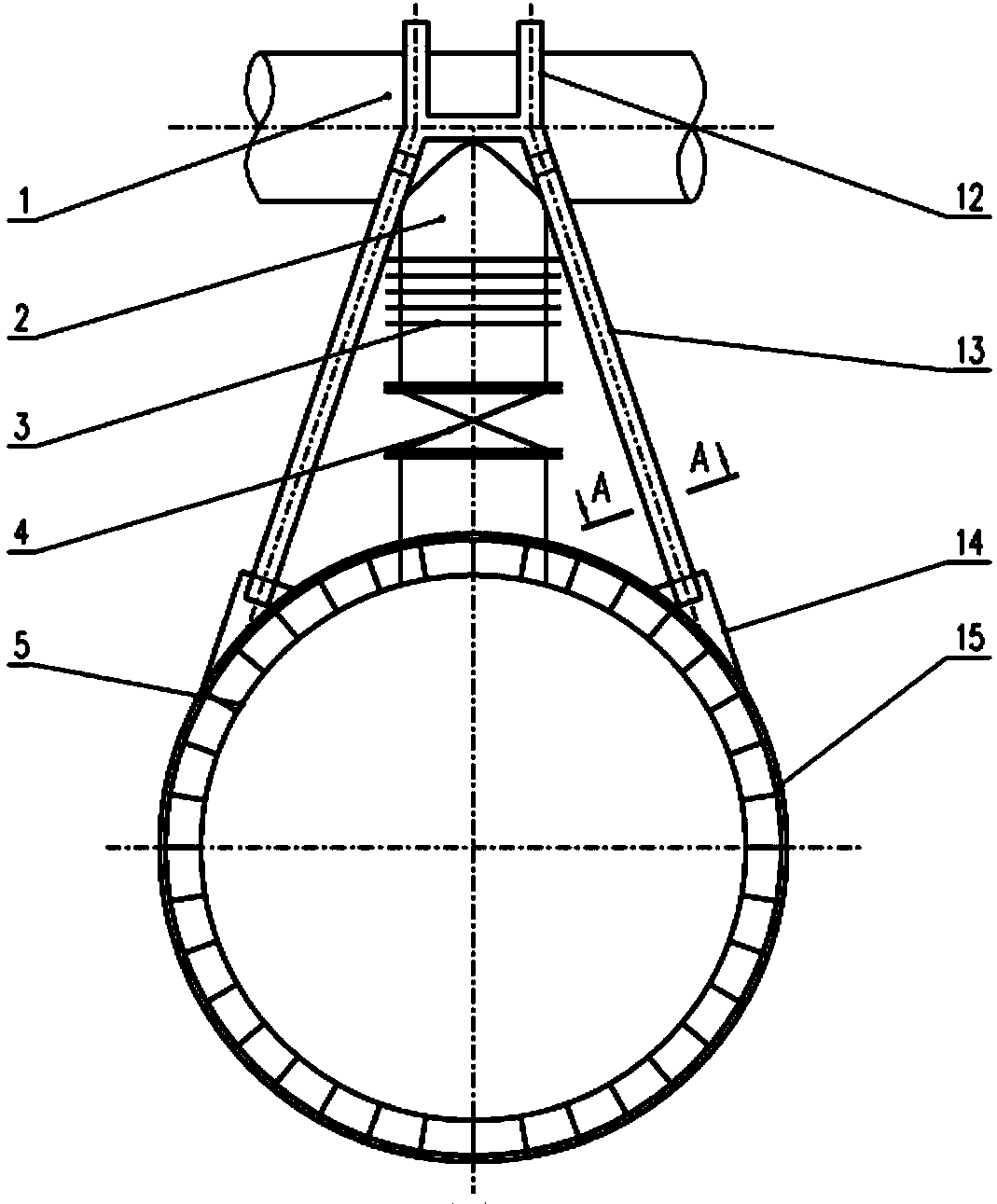

[0039] Figure 5 It is another specific embodiment of the present invention.

[0040] Depend on Figure 5 It can be seen that this embodiment includes: hot blast main pipe 1, hot blast branch pipe 2, hot blast branch pipe compensator 3, hot blast valve 4, hot blast stove shell 5, hot blast pipe upper tie rod support 12, flexible large tie rod 13, connecting plate, 14, Hot blast furnace shell reinforcement ring 15.

[0041] For some new construction or renovation projects, the height of the hot blast stove is limited, and the reinforcing ring 15 cannot be made into a 360 ° complete ring, which can be disconnected at the hot blast outlet.

[0042] This embodiment is similar to Embodiment 1, except that the reinforcement ring 15 of the shell of the hot blast stove is not a 360° full ring, but is disconnected at the outlet of the hot blast.

[0043] A large tie rod support 12 is arranged at the fork where the hot blast main pipe 1 is connected with the hot blast branch pipe 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com