Automatic control system for changing combustion rhythm of hot blast furnace along with blast temperature of high furnace

A hot blast stove and blast temperature technology, which is applied to blast furnace details, blast furnaces, blast furnace parts, etc., can solve problems such as automatic combustion of hot blast stoves, dynamic control of hot blast stove combustion rhythm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

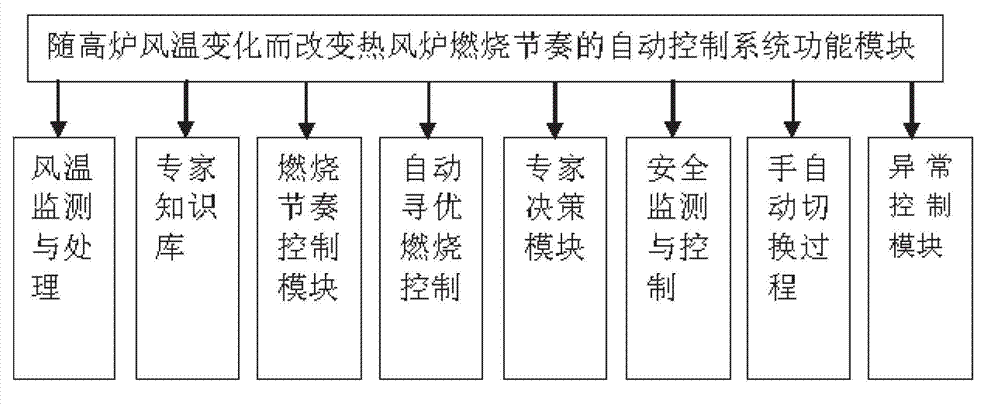

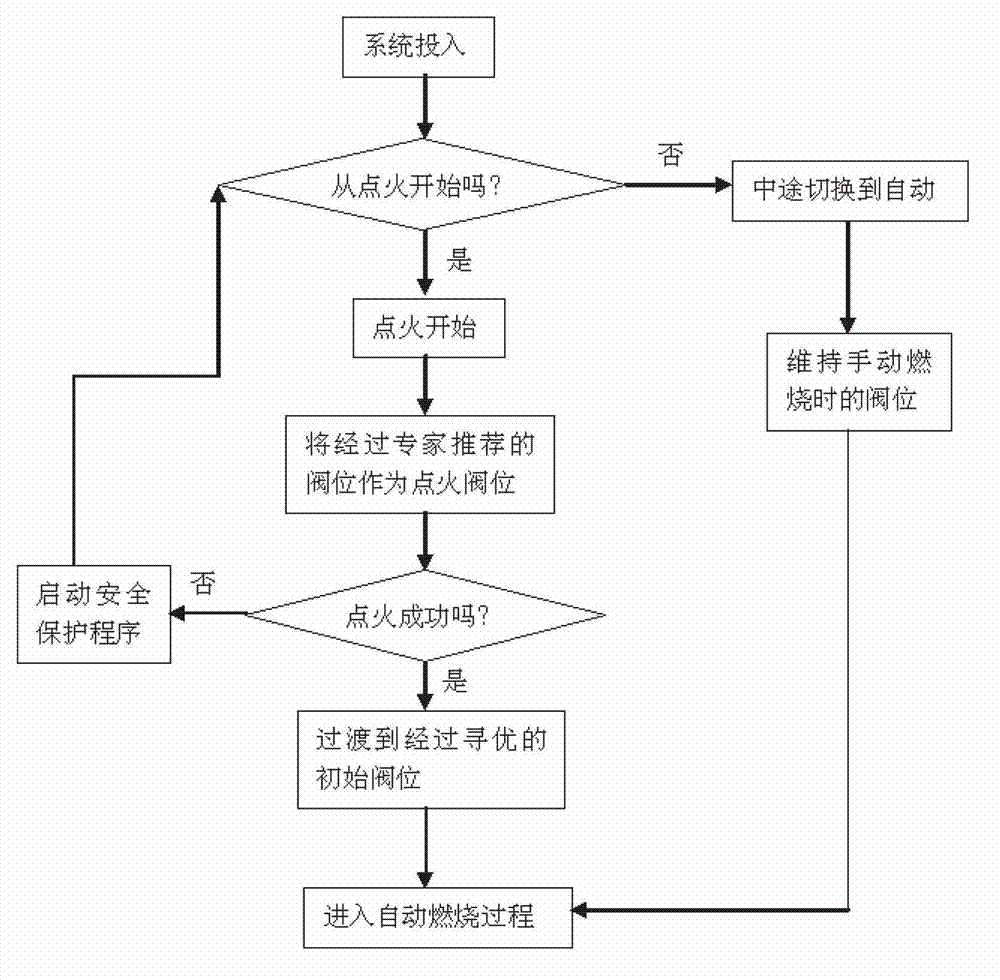

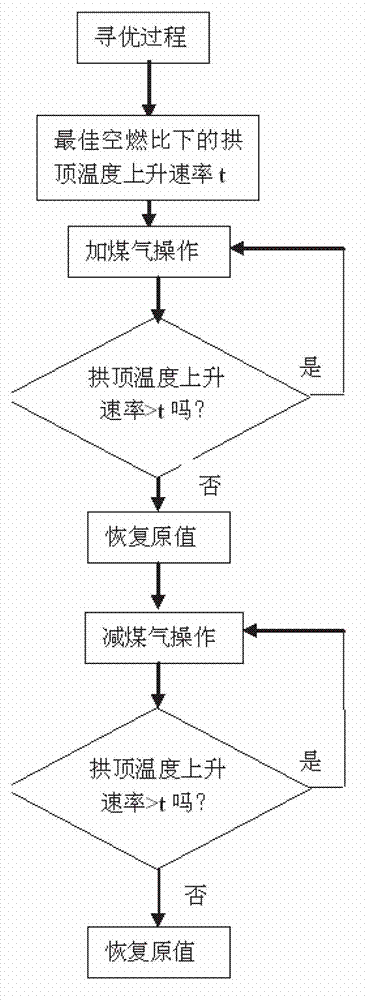

[0043] The present invention proposes a control system for changing the combustion rhythm of a hot blast stove based on the operation change of the blast furnace air temperature, which applies an expert system and fuzzy control theory. The detailed description is as follows in conjunction with drawings and examples:

[0044] The main parameters of the blast furnace hot blast stove selected in this embodiment are:

[0045] Blast furnace volume: 5500m 3

[0046] Number of hot blast stove: 4

[0047] Combustion system: two burns and two free

[0048] Hot blast stove type: top combustion type

[0049] Fuel type: blast furnace gas

[0050] Burning cycle: 120 min

[0051] The highest value of exhaust gas temperature: 450℃

[0052] The system can be divided into two stages: the determination stage of the optimal combustion parameters before combustion and the control stage of the normal combustion process. The flow chart of the overall control is as figure 1 Shown.

[0053] (1) Blast furnace air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com