Harmonization control method for blast furnace hot blast stove system

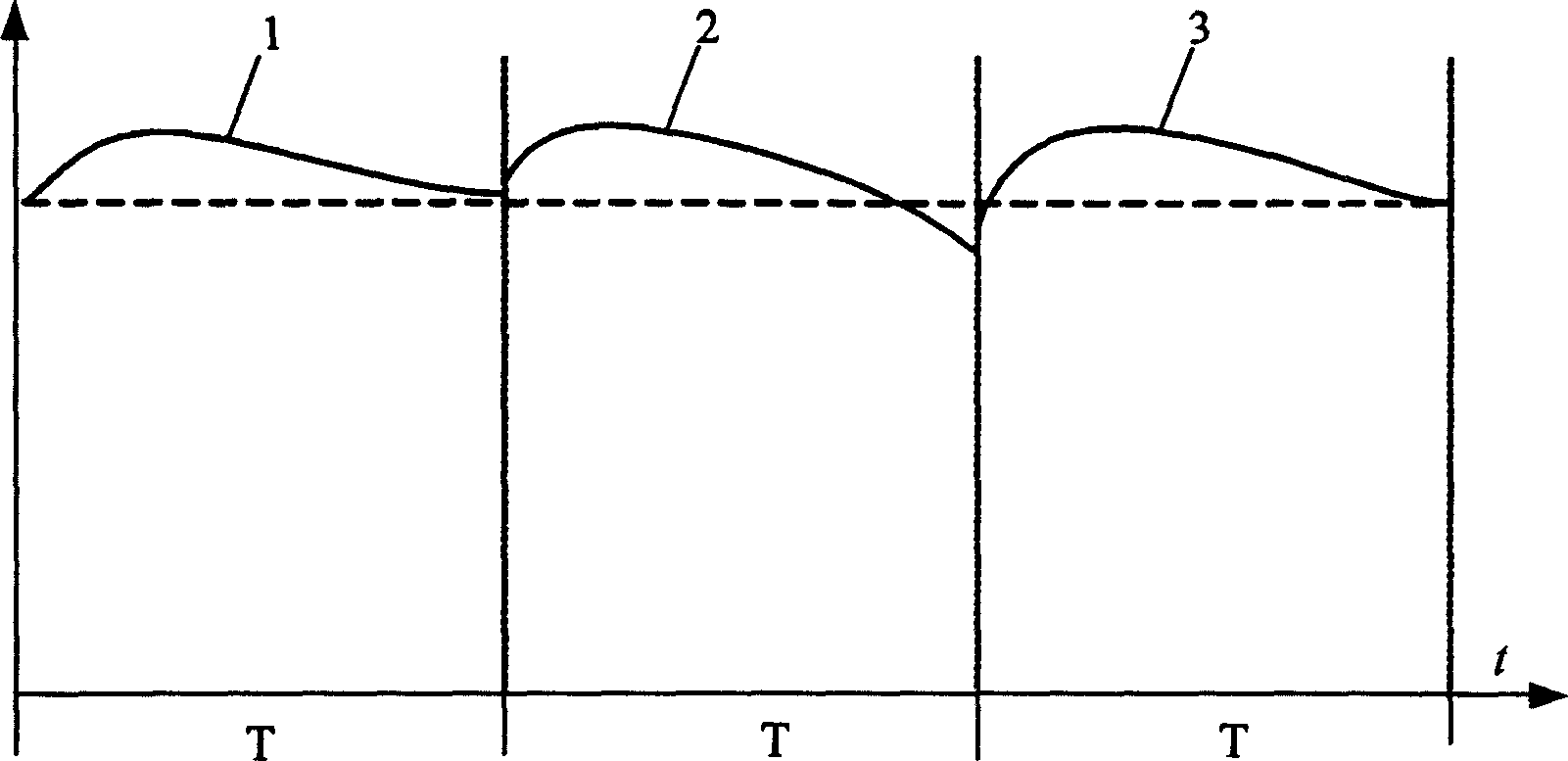

A technology of coordinated control and hot blast stove, applied in blast furnace, temperature control, blast furnace details, etc., can solve problems such as large gas consumption, energy waste, neglect, etc., and achieve the effect of increasing supply air temperature and reducing supply air temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

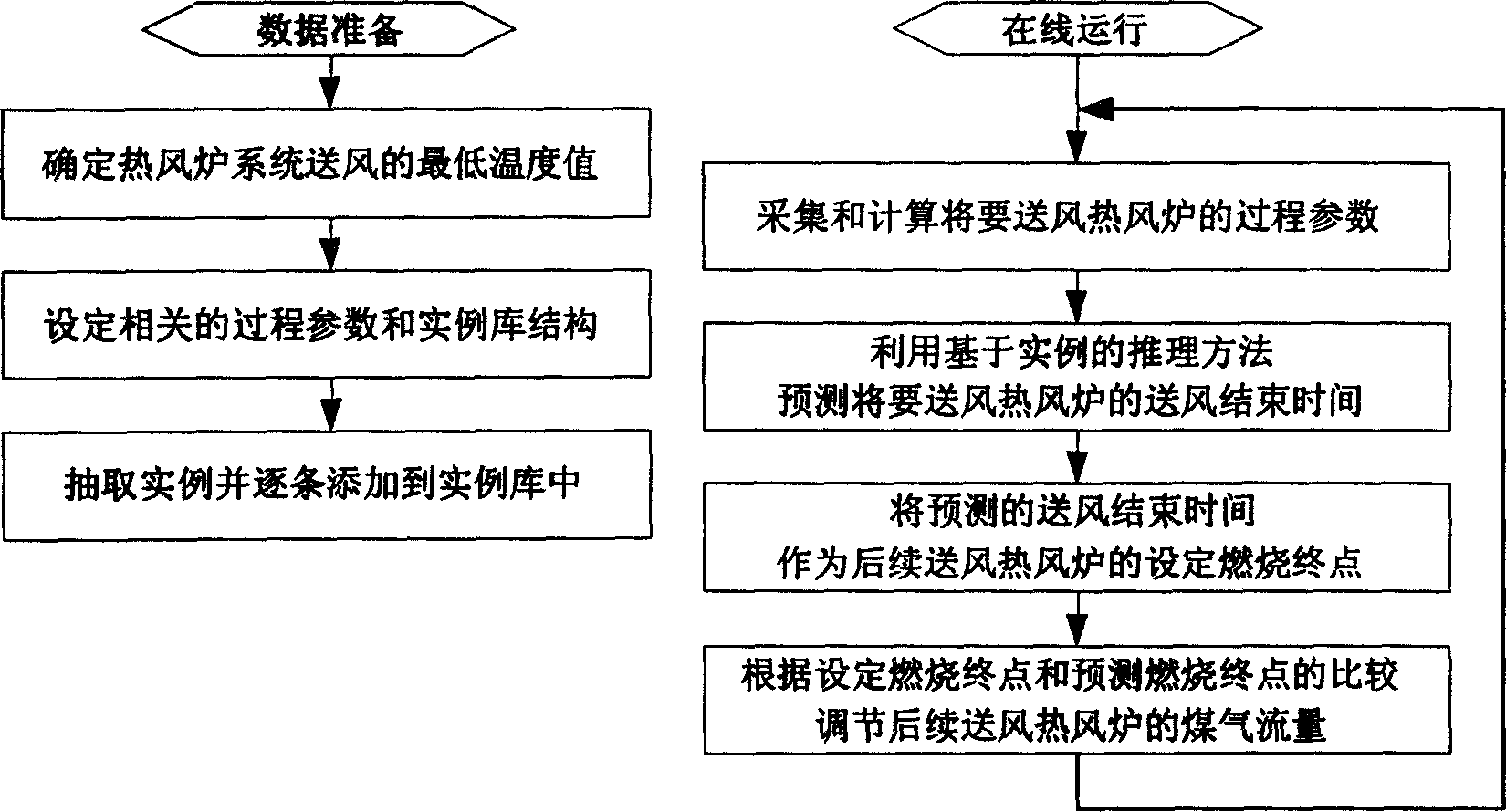

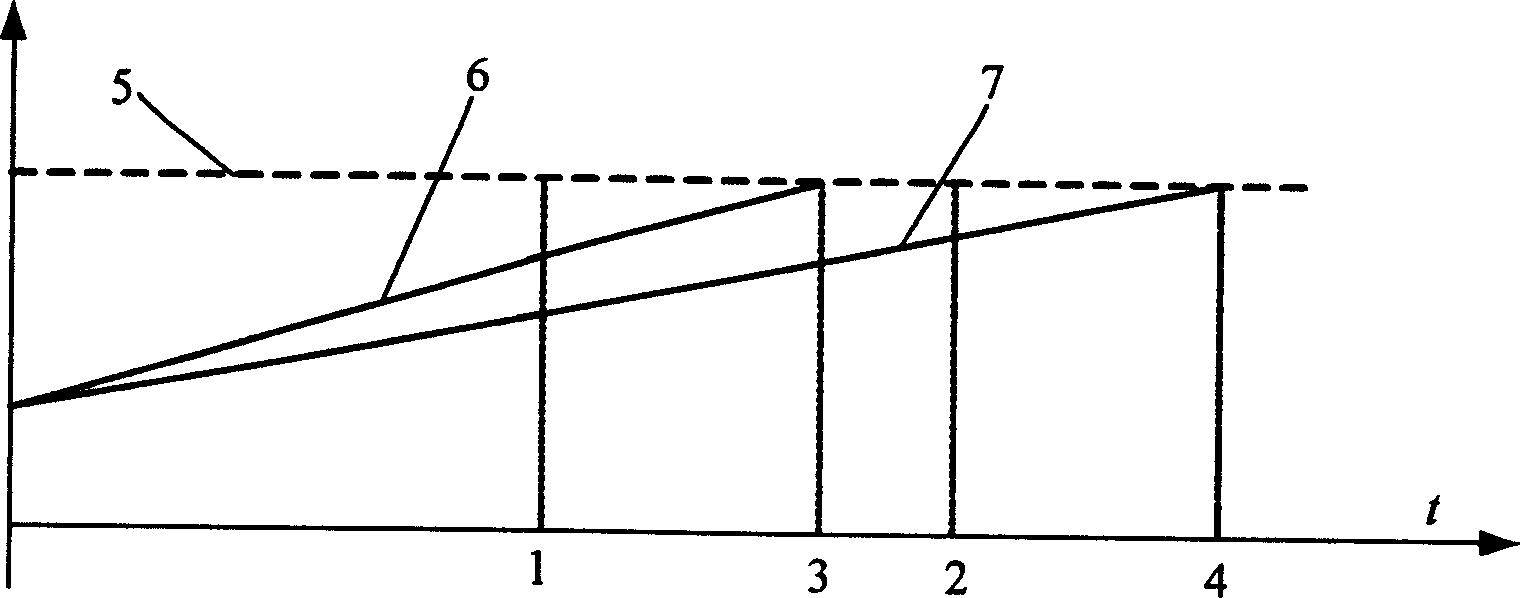

[0036] The coordinated control method of the blast furnace hot blast stove system proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and embodiments:

[0037] The blast furnace hot blast stove coordinated control control proposed by the present invention is based on the prediction of the blast furnace air supply time. The following takes a specific blast furnace hot blast stove system as an example to describe its working process in detail. The main blast furnace hot blast stove selected in this embodiment The parameters are: blast furnace volume 230M 3 , equipped with 3 hot blast stoves, adopting the combustion system of 2 combustion and 1 delivery; the hot blast stoves are top-fired, all the fuel used is blast furnace gas, and the upper limit of the exhaust gas temperature specified in the regulations is 450°C.

[0038] The flow of the coordinated control method for the blast furnace hot blast stove system in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com