High-temperature and low-energy-consumption running state estimation and optimization method for hot air furnace system

A technology of operation state and optimization method, which is applied in furnaces, blast furnaces, heating furnaces, etc., can solve the problems of blast furnace gas consumption, failure to obtain significant improvement, and lack of comprehensive research and optimization of hot blast stove systems, so as to reduce ironmaking costs , Realize the effect of circular economy and energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

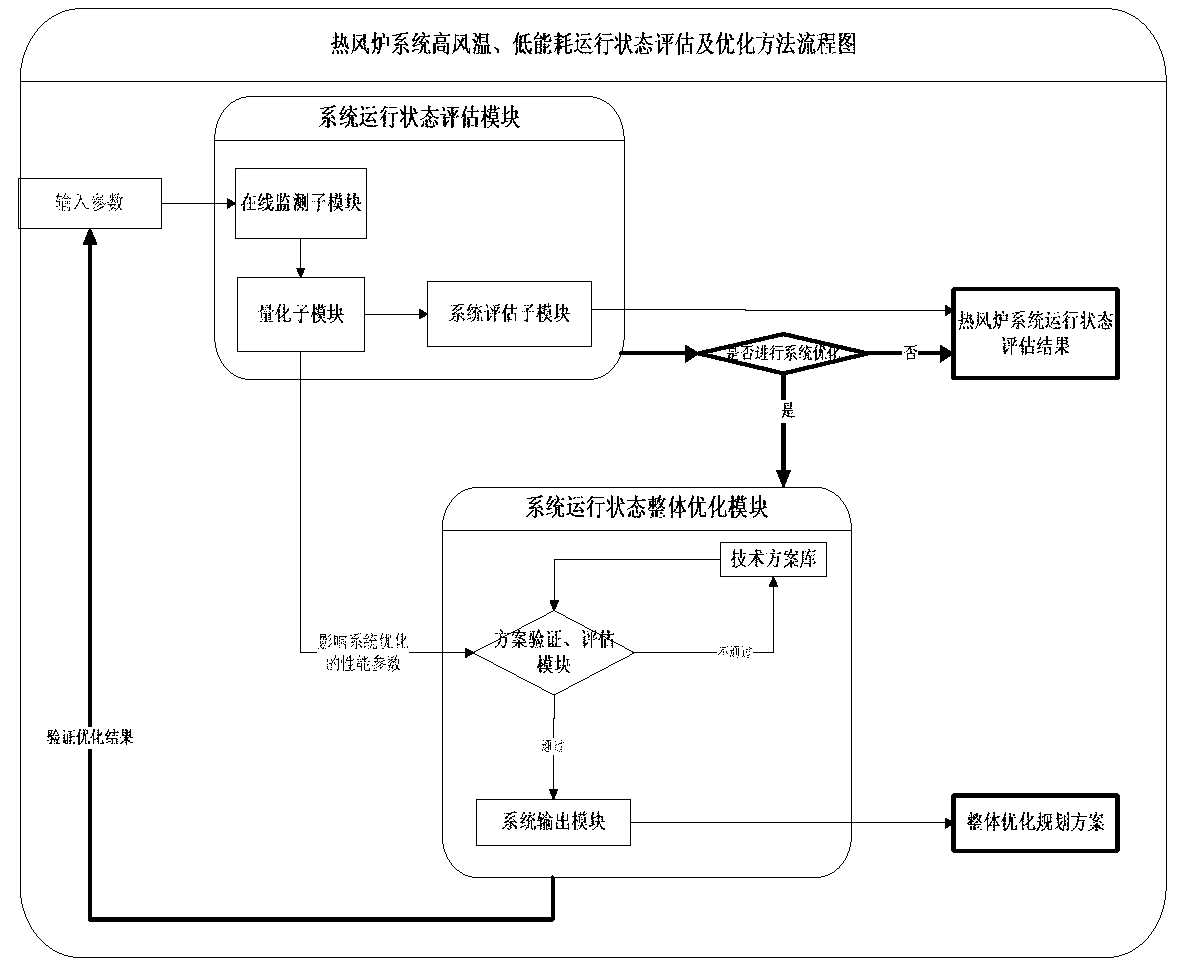

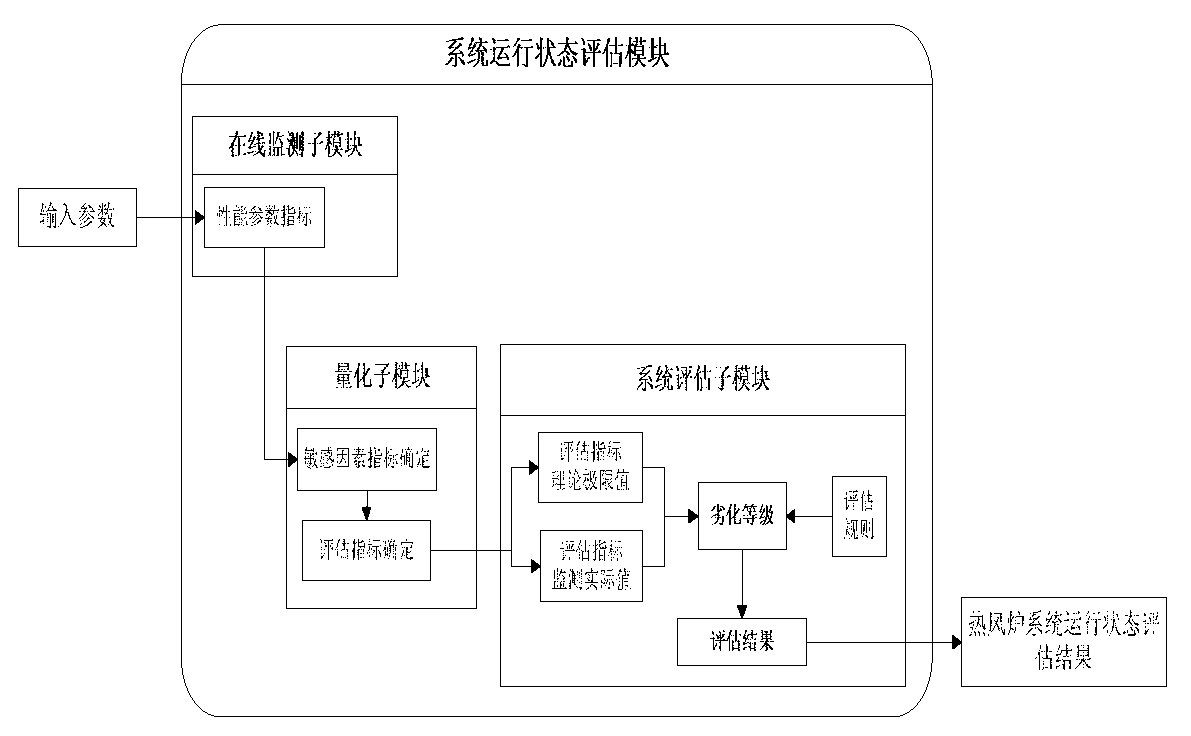

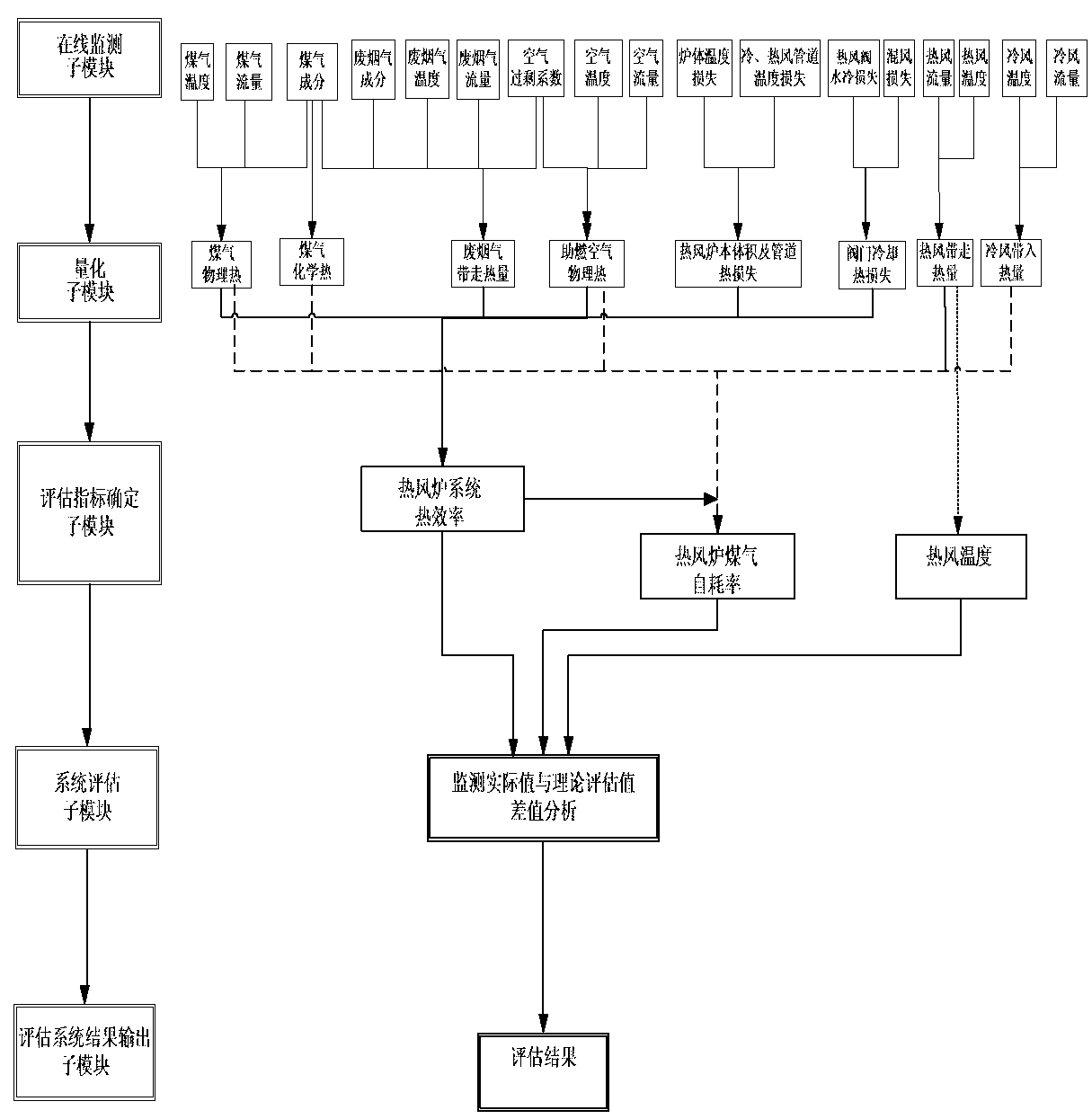

[0036] A method for realizing the overall optimization of the system's operating state by evaluating the operation of the hot blast stove is a method implemented by a computer system. There is a technical solution library, and the technical solution library includes: sensitive performance optimized for the thermal efficiency of the hot blast stove system A parameter table, a sensitive performance parameter table optimized for the gas self-consumption rate of the hot blast stove, a sensitive performance parameter table optimized for the hot blast temperature, and a technical measure plan table for the above-mentioned optimized sensitive performance parameter table; the method includes :

[0037] a. Set the predetermined evaluation indicators for the operation of the hot blast stove system, the indicators include the thermal efficiency of the hot blast stove system, the gas self-consumption rate of the hot blast stove, and the temperature of the hot blast;

[0038] b. Collect da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com