Slag washing water steam recycling and white fog removing system and recycling method

A recovery method and water vapor technology, which are applied in the improvement of process efficiency, details of furnaces and blast furnaces, etc., can solve the problem of increasing the investment and operation cost of environmental protection facilities of enterprises, not much research on white smoke elimination methods, consuming cold sources and adding heat exchange. Equipment and other problems, to achieve the effect of easy operation and maintenance, simple equipment, and prevention of white smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

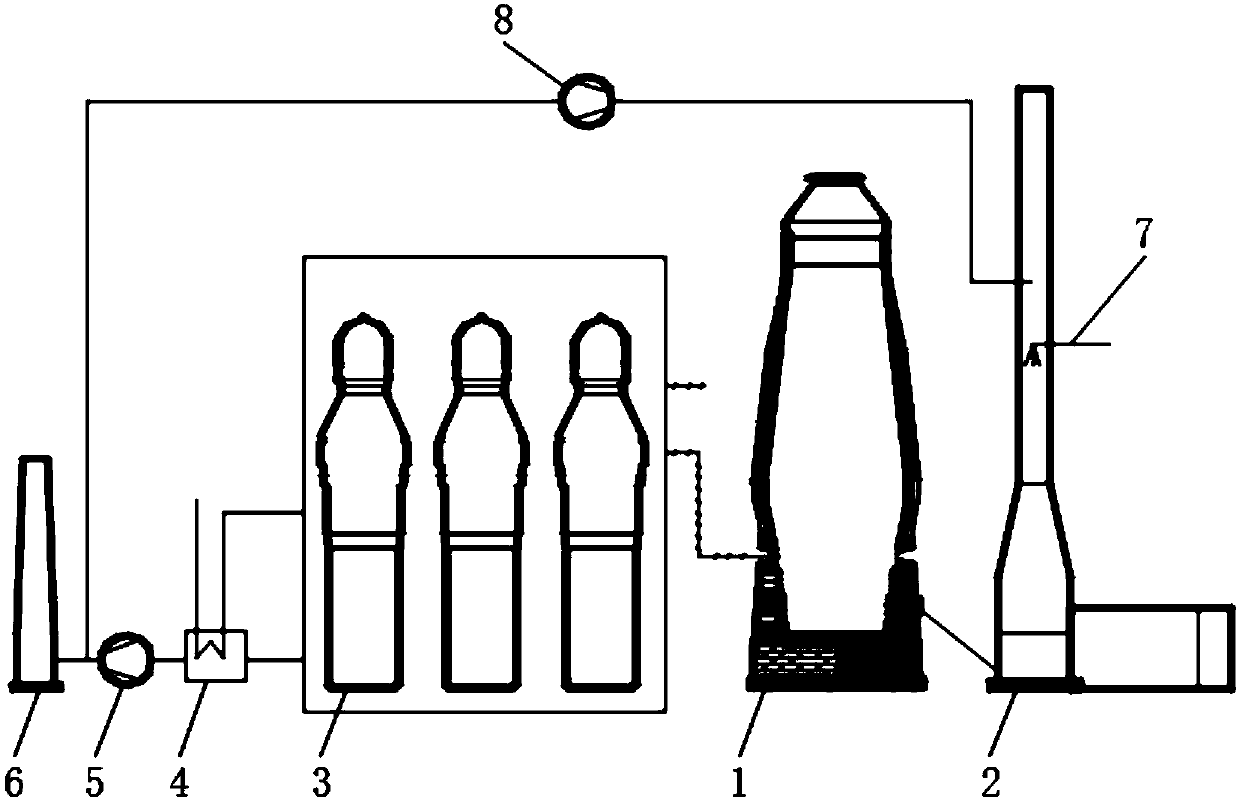

Image

Examples

Embodiment 1

[0038] Embodiment 1: The 80°C water vapor entering the slag flushing steam chimney 2 from the slag flushing facility has a saturated steam pressure of 47.4kPa, and the middle part of the slag flushing steam chimney 2 is in direct contact with the water sprayed by the spray device 7 to cool down At 60°C, the saturated steam pressure drop is 19.9kPa, and the condensed amount of water vapor exceeds 55%. After the condensation and nucleation of atomized water droplets sprayed down, most of the water droplets flow back to the slag flushing facility through the chimney wall without being condensed. Part of the liquid droplets entrained by the water vapor continue to go upward, and mix with the exhaust gas of the hot blast stove at 150 ° C to raise the temperature. By adjusting the amount of exhaust gas introduced, the mixed temperature is raised to 95 ° C. Considering factors such as temperature and the amount of flue gas introduced, this When the water vapor saturation is much lower...

Embodiment 2

[0039] Embodiment 2: The water vapor at 75°C entering the slag flushing water steam chimney 2 from the slag flushing facility has a saturated steam pressure of 38.6kPa, and directly contacts with the water sprayed from the spray device 7 to cool down to 50°C, and the saturated steam The pressure drop is 12.3kPa, and the condensed amount of water vapor exceeds 65%. After the condensation and nucleation of atomized water droplets sprayed down, most of the water droplets flow back to the slag washing facility through the chimney wall, and part of the liquid is entrained by the uncondensed water vapor. The drop continues to rise, mixes with the exhaust gas of the hot blast stove at 150°C to raise the temperature, and adjusts the amount of exhaust gas introduced to raise the mixed temperature to 80°C. Considering factors such as temperature and the amount of introduced flue gas, the water vapor saturation at this time is much higher. Below 30%, the mixture of flue gas and water vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com