Offshore natural gas hydrate row-type horizontal well mining method

A technology for horizontal wells and hydrates, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problems of unsafe heating, stagnation, and danger, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

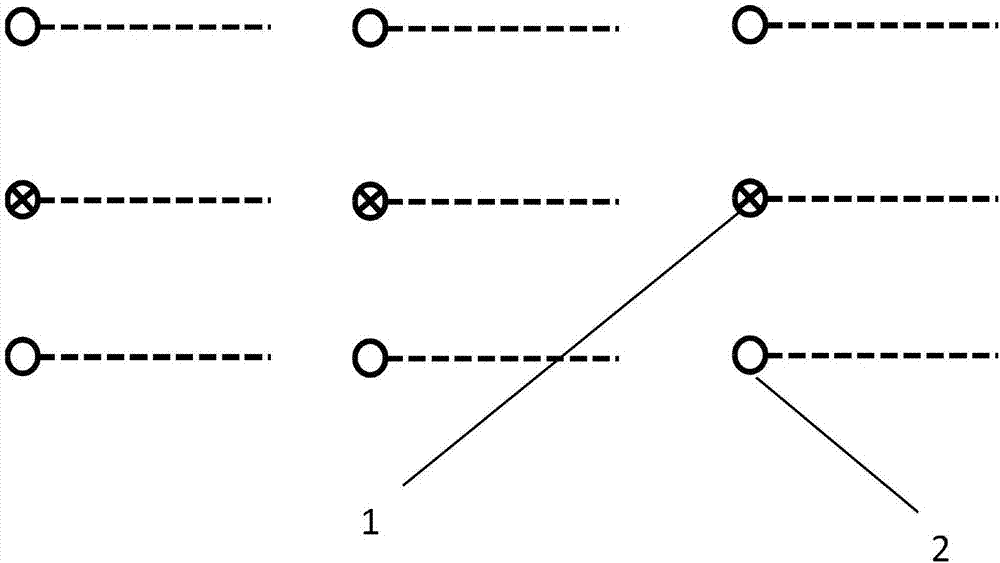

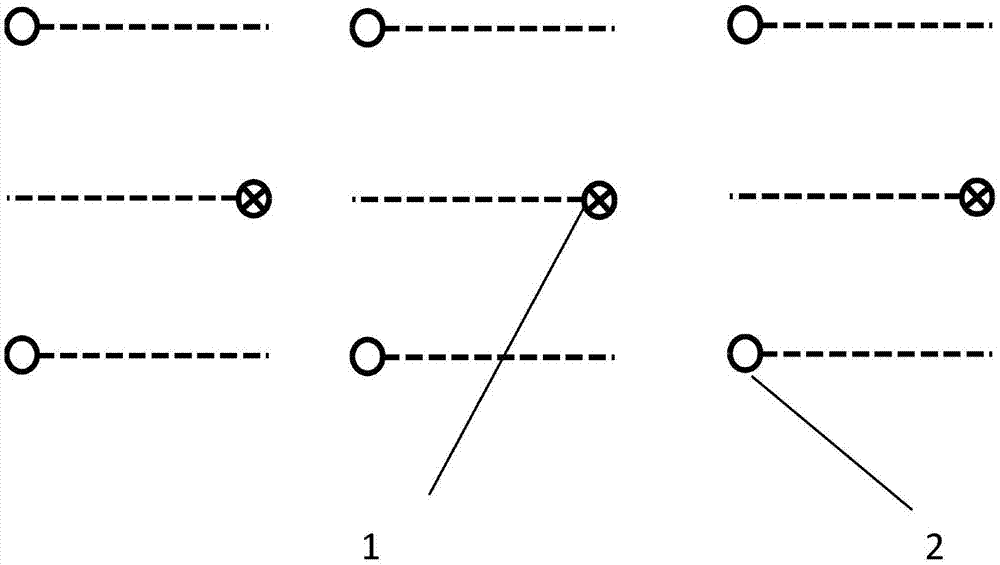

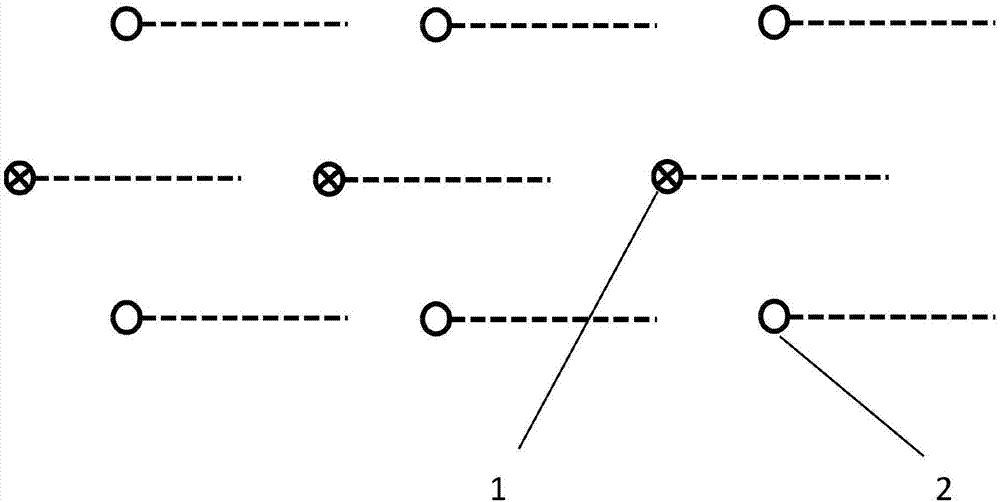

[0057] An embodiment of the present invention provides a method for exploiting offshore natural gas hydrate row-type horizontal wells. The method includes: combining geological data, arranging a row-type horizontal well pattern and supporting well completion operations for the target storage, and implementing horizontal wells after completion. Depressurize production until there is no economic benefit. After depressurization production, perform fracturing operations on horizontal wells, and then arrange surface supply systems and downhole water injection systems in water injection wells, inject displacement water into natural gas hydrate reserves through water injection wells, and Collect natural gas and formation water.

[0058] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com