Multi-ring matrix burden distribution process for bell-less top of blast furnace

A cloth and blast furnace technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as difficulty in uniform and active hearth work, difficulty in adjusting gas flow, etc., and achieve the effect of reducing the adjustment effect and reducing the fuel ratio

Inactive Publication Date: 2010-09-29

SHOUGANG CORPORATION

View PDF0 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, the above charging system and the simple multi-ring distribution method have their limitations in the production process, for example, it is difficult to adjust the gas flow, and it is difficult to work evenly and actively in the hearth.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

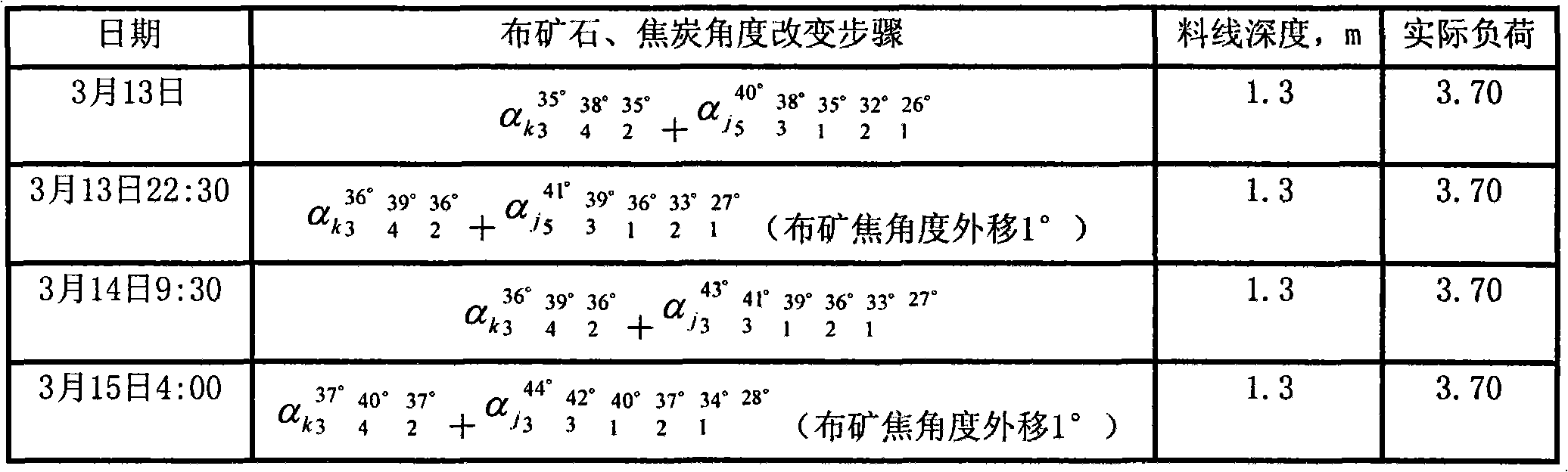

[0013] Specific implementation case (Shougang No. 2 blast furnace with a capacity of 1780 liters)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

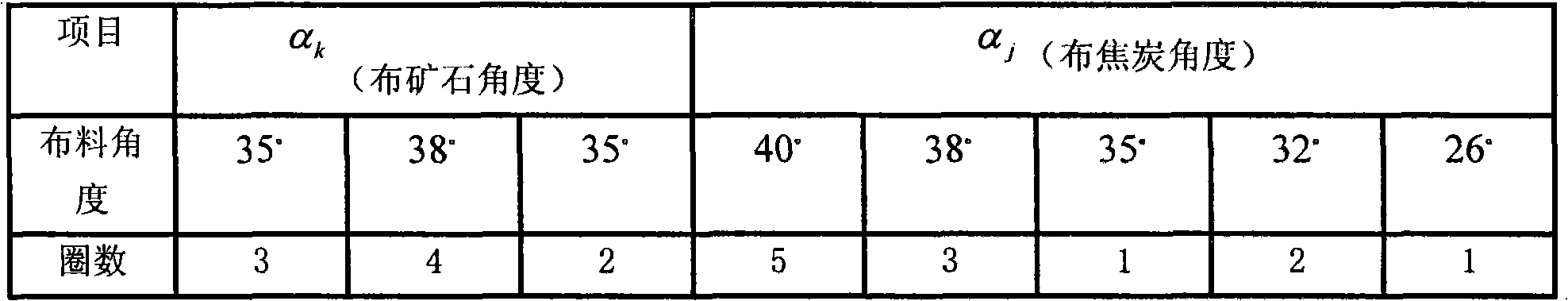

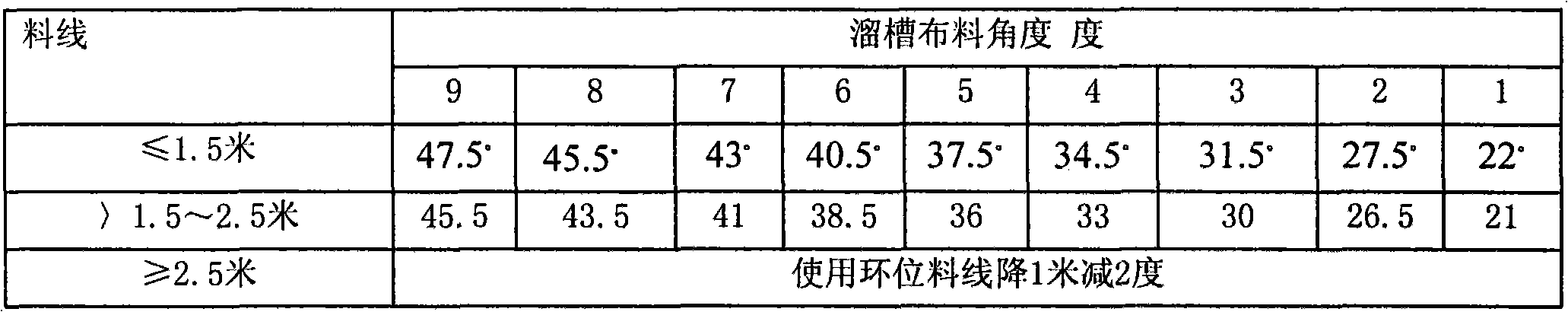

The invention relates to a multi-ring matrix burden distribution process for a bell-less top of a blast furnace, belonging to the technical field of burden distribution of blast furnaces. A multi-ring burden distribution process is combined with a burden distribution matrix, and the burden distribution matrix is set according to 9-11 ring sites; generally, 4-6 ring sites are selected for distributing coke, and 3-5 ring sites are selected for distributing ore; the number of turns on each ring site for distributing coke is selected preferably to enable the coke to be laid horizontally; the number of turns on each ring site for distributing ore is selected to control the ore coke ratio on the furnace throat radius, thereby controlling radial distribution of coal gas flow; and the number of turns for distributing coke and distributing ore is generally controlled to be 10-14 turns. The invention can obtain furnace throat coal gas distribution in which coal gas at edges has certain passages and coal gas in the center develops, and the burden distribution is flexible and adjustable, thereby keeping stable and smooth operation of the blast furnace, realizing the purposes of opening the center and stabilizing the edges, improving the utilization ratio of coal gas, reducing the fuel ratio of the blast furnace, and further reducing the production cost.

Description

technical field [0001] The invention belongs to the technical field of blast furnace material distribution, in particular to a multi-ring matrix material distribution method on a bellless top of a blast furnace. Background technique [0002] Blast furnace distribution method refers to the reasonable selection and distribution of the charging sequence, loading method, rotating chute α angle, material line and batch weight when the charging is loaded into the furnace. The principle of the blast furnace material distribution method is to ensure the reasonable distribution of gas, improve the utilization rate of gas, and ensure the smooth operation of the blast furnace. Blast furnace material plays a key role in the stable operation of the blast furnace and the utilization of gas, that is, it plays a decisive role in the technical and economic indicators of the blast furnace - output and coke ratio. [0003] Bellless stove top cloth has gained certain experience in many enterpr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21B7/00

Inventor 竺维春齐树森王冬青

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com