Method for determining ore batches and furnace top pressure according to blast furnace bosh gas volume indexes

A technology of furnace top pressure and blast furnace bosh, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems that cannot directly reflect the blast furnace smelting process, and achieve the goal of promoting technical and economic indicators, promoting smooth production, and promoting improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

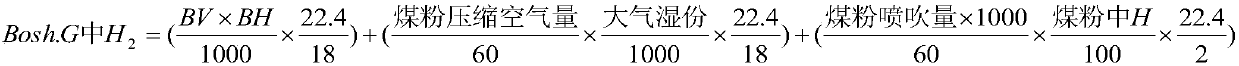

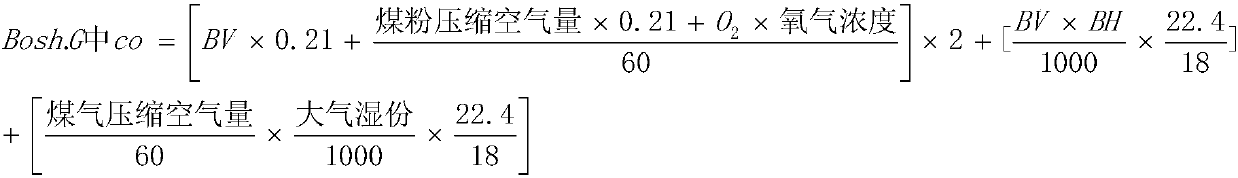

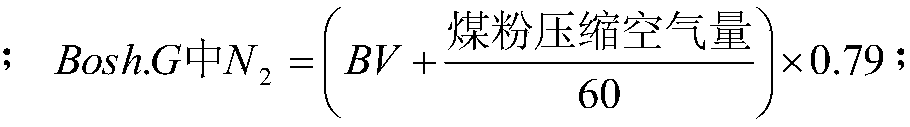

Method used

Image

Examples

Embodiment Construction

[0022] According to the statistics of production practice data, a blast furnace is 8300~10500m 3 / min bosh gas volume, see the table below for different ore batches and furnace top pressures.

[0023]

[0024] In a blast furnace bosh gas volume index by 52m 3 / (min.m 2 ) continuously to 67m 3 / (min.m 2 ), the ore batch and furnace top pressure are positively correlated with the bosh gas volume index. According to the difference of the bosh gas volume index, the ore batch is gradually increased from 120t to 136t, and the furnace top pressure is also gradually increased from 220Kpa to 260KPa. And the regression obtains the following 2 formulas:

[0025] Mine batch=-46.71+2.65*bosh gas volume index+5~15, the unit is t;

[0026] Furnace top pressure = 12.73+3.69*bosh gas volume index+15~30, the unit is KPa;

[0027] 3500~5000m 3 The upper limit value for large-scale blast furnace is 1500~3500m 3 Level small blast furnace removes the limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com