Technology for recovering iron ore concentrate and coke powder from blast furnace gas dust or gas sludge

A technology for blast furnace gas ash and gas mud is applied in the field of comprehensive utilization of mineral resources and solid waste, and achieves the effects of simple and continuous process, strong industrial promotion prospects and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

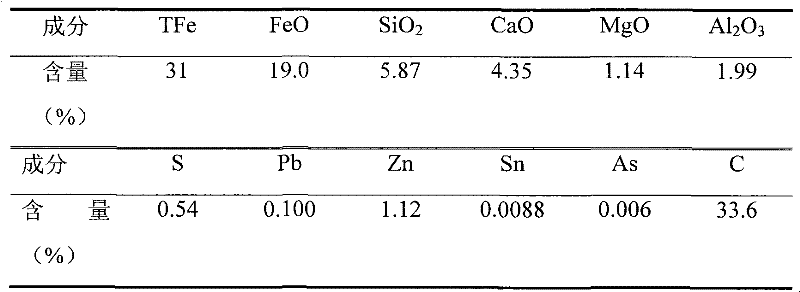

[0015] Table 1-1 lists the main chemical components of gas ash from blast furnace solid waste from a steel company. TFe is 31%, carbon content is 33.6%, and SiO 2 It is 5.87%, CaO is 4.35%, and the content of S, Zn, and Pb is also relatively high.

[0016] Table 1-1 The main chemical composition of gas ash in a steel company / %

[0017]

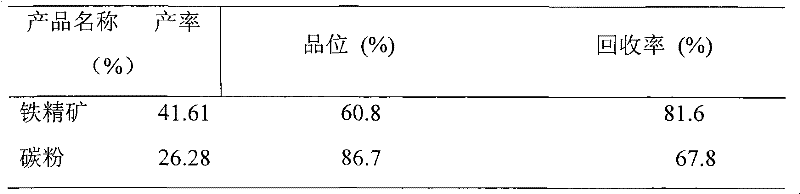

[0018] According to the above analysis, the particle size of gas ash -0.074mm accounts for about 40%. It is sent to the rotary kiln for drying, preheating, magnetization roasting, roasting temperature is about 800℃, roasting time 45min, roasted mineral water quenched and sent to wet type The grinding particle size of the ball mill is -0.074mm, which accounts for about 65%; the fine-grained mineral material is mixed with tap water to form a slurry with a slurry concentration of 25%. The slurry is sent to a wet drum weak magnetic separator, and iron concentrate is obtained by weak magnetic separation (0.12T) Mine and primary tailings to obtain iron c...

Embodiment 2

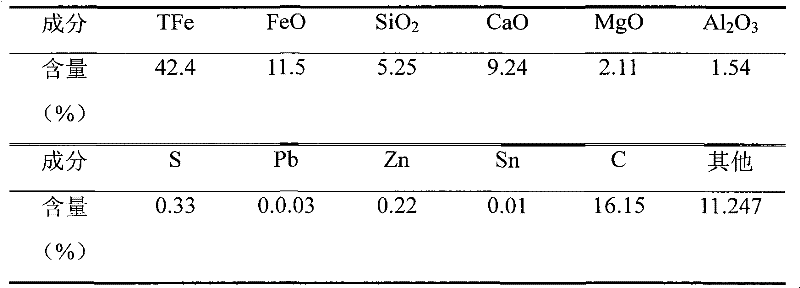

[0023] Table 2-1 shows the main chemical composition of gas mud from blast furnace solid waste of a steel company. The main minerals of gas mud are hematite and magnetite, and the minor minerals are olivine, feldspar silicate minerals, coke powder and a small amount. quartz. The content of hematite is 45%-50%, the maximum particle size is 0.07mm, mostly 0.03-0.05mm, mostly hematite single crystal, and a small amount of hematite is distributed in the silicate cement phase.

[0024] Table 1-2 The main chemical components of blast furnace gas mud in a steel company

[0025]

[0026] The process of recovering iron ore and carbon powder is as follows: the gas mud is directly sent to the boiling furnace for drying, preheating, magnetized roasting, the roasting temperature is about 750℃, and the roasting time is 15-30 minutes, and the roasted mineral water is quenched and sent directly to the wet ball mill Grinding particle size -0.074mm accounts for 70%; obtain fine-grained mineral mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com