Method for producing active pulverized lime by utilizing coal gas to calcine limestone through suspended state pre-heating decomposing furnace

A technology for calcining limestone and limestone powder, which is applied in lime production and other fields, and can solve problems such as high quality requirements for maintenance personnel and technicians, low thermal efficiency, and waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

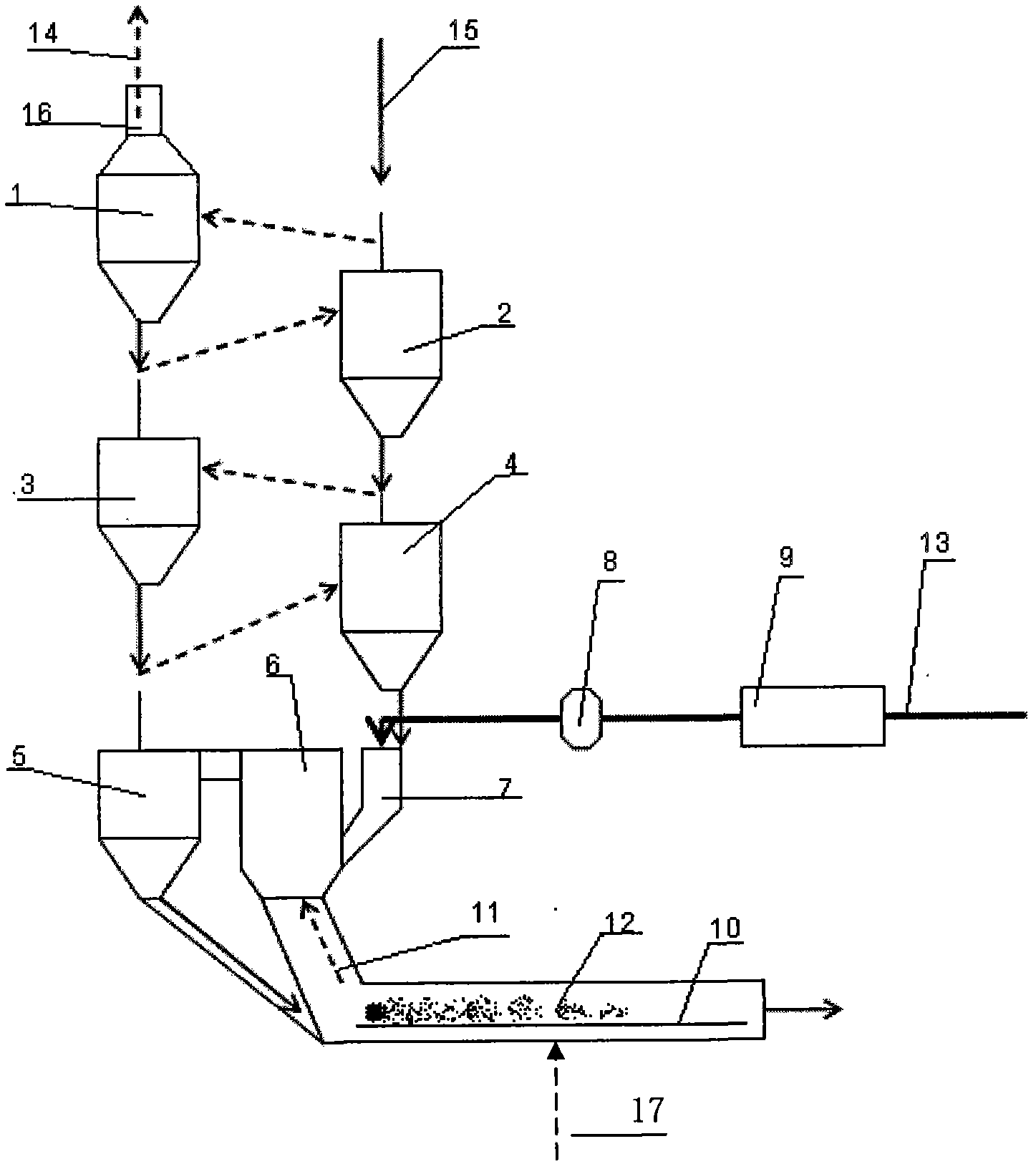

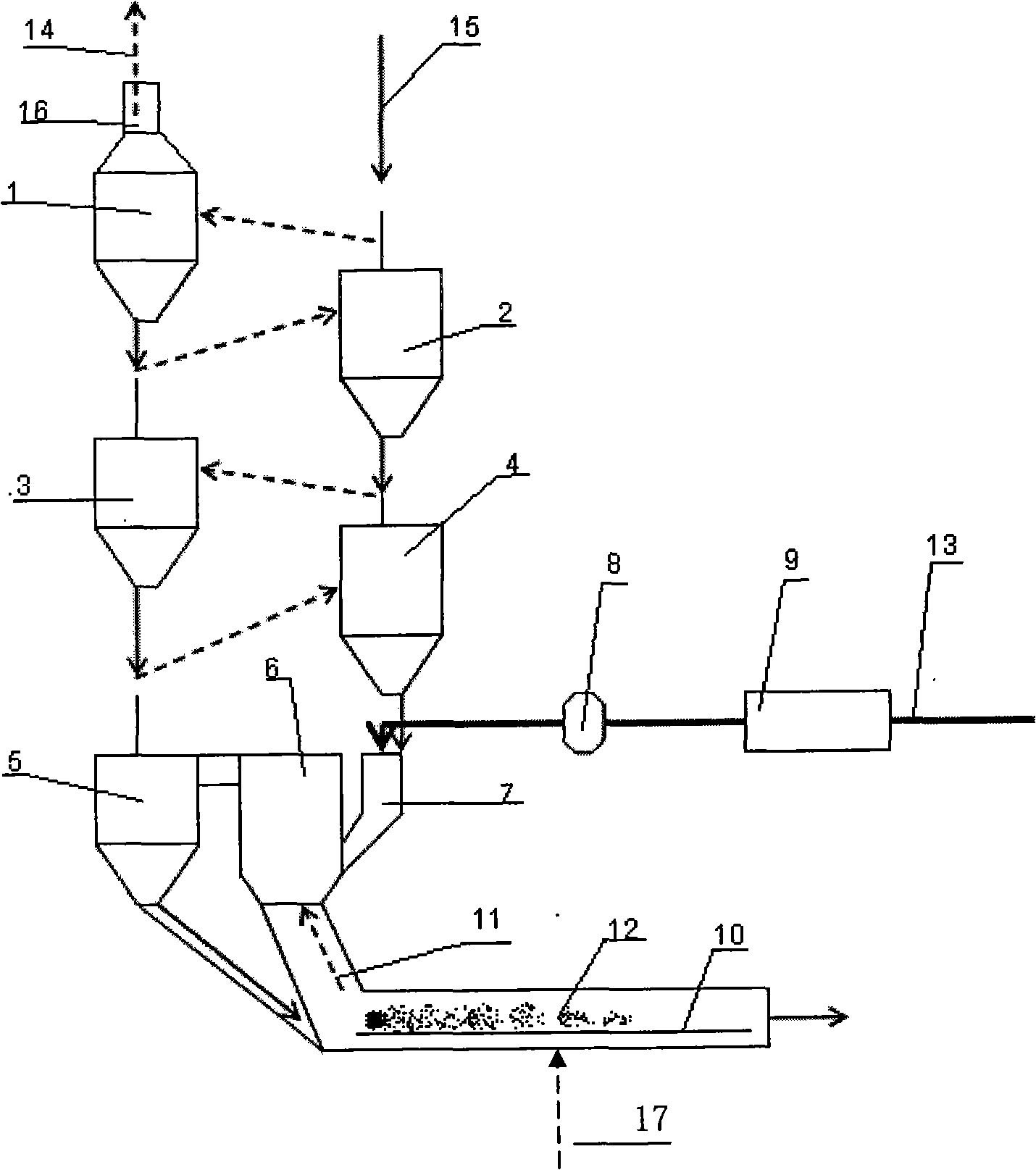

[0007] A method for producing active lime powder by calcining limestone with gas, the steps are as follows:

[0008] 1) limestone is ground into limestone powder;

[0009] 2) Start the high-pressure fan at the outlet of the first-stage cyclone as the suspension power source of limestone powder, and transport the gas with large pressure fluctuations in the steel production process to the gas stabilizing cabinet through the gas pipeline, and the gas is stabilized by the gas stabilizing cabinet , After the gas flow is adjusted by the control valve, it is sent to the combustion and decomposition chamber through the gas pipeline for combustion, and the combustion forms a high-temperature flame to calcine and decompose the limestone;

[0010] 3) Limestone powder is added from the feed port of the secondary cyclone, and the material flow formed by the limestone powder enters the primary cyclone along with the airflow of the secondary cyclone;

[0011] 4) The limestone powder is susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com