Process for preparing methanol by making steel enterprises coke oven gas and converter gas as raw material

A technology for coke oven gas and converter gas, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, and organic chemistry, etc., can solve the problems of waste of chemical raw material resources, high content of inert components, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

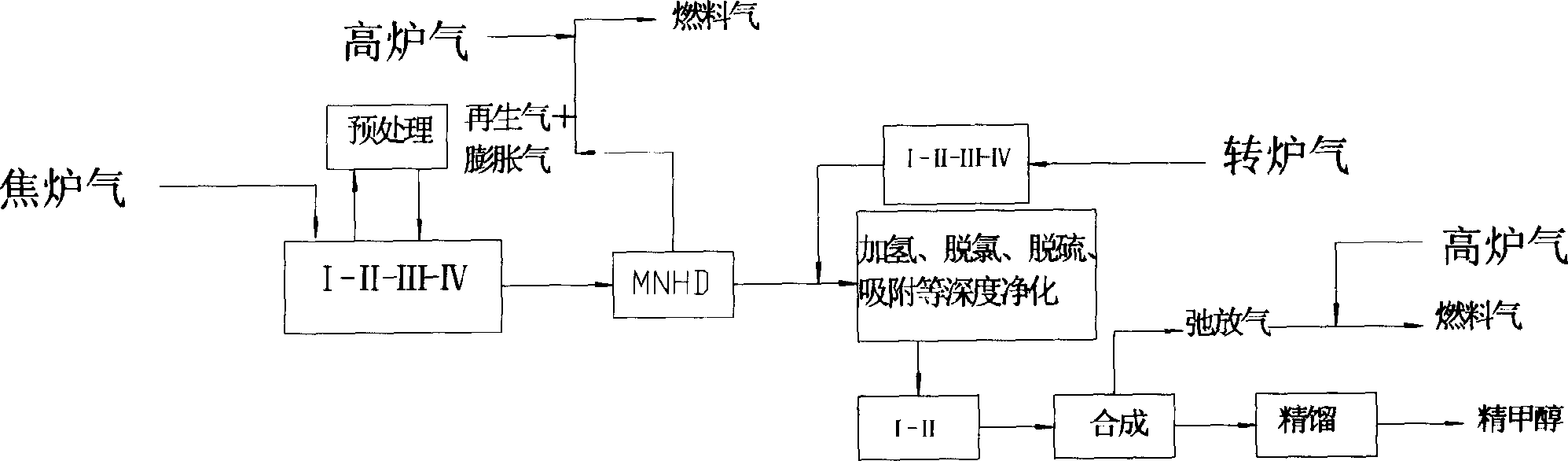

[0014] Coke oven gas contains 45%~60% hydrogen, 5%~7% CO, 2.0%~3.5% CO 2 , 22%~28%CH 4 , if a large amount of H in the coke oven gas 2 Reasonably mixed with converter gas containing 50% to 55% CO, it can be made into raw material gas that meets the requirements of methanol synthesis, so that coke oven gas and converter gas can be used reasonably and effectively.

[0015] The present invention utilizes the active ingredient H in the coke oven gas 2 and CO in converter gas and CO 2 To adjust the carbon-hydrogen ratio to meet (H 2 -CO 2 ) / (CO+CO 2 )=2.05~2.10 gas as raw material gas for methanol synthesis.

[0016] Utilization of active ingredient H in the coke oven gas said by the present invention 2 CO in converter gas can be directly blended with coke oven gas and converter gas, or H can be separated from the two gases 2 and CO and then re-deploy or separate H from coke oven gas 2 Mix with converter gas or separate CO from converter gas and mix with coke oven gas, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com