A kind of cutting fluid for precise manufacturing of automobile aluminum wheel hub and preparation method thereof

A precision manufacturing and cutting fluid technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as poor lubricity, short replacement cycle, carcinogenicity, etc., to improve lubricity and machining accuracy, reduce tool wear, and protect physical and mental health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

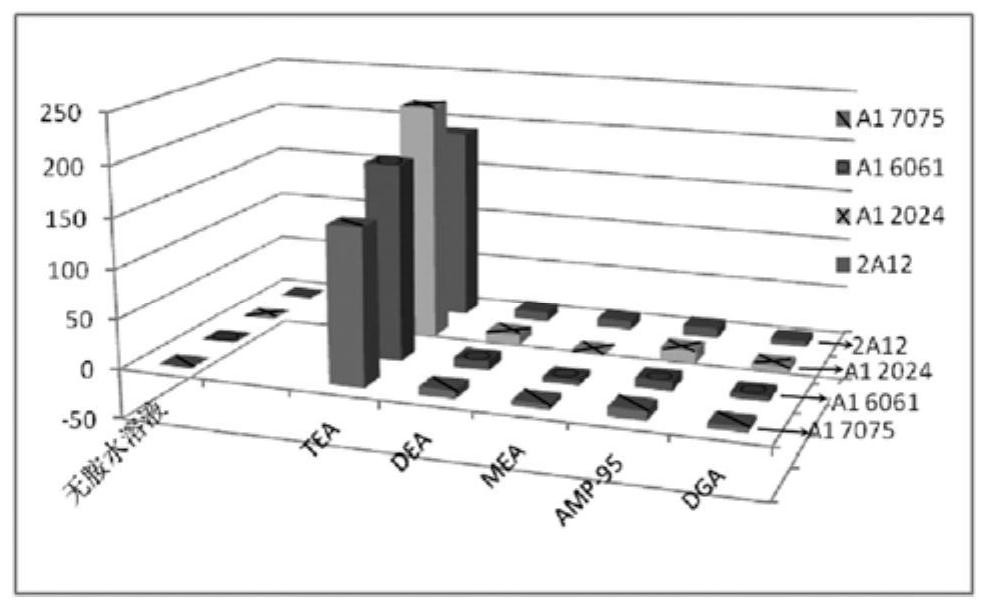

Image

Examples

Embodiment Construction

[0045] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples. Those skilled in the art should understand that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0046] In the examples, the experimental methods used are conventional methods unless otherwise specified, and the materials and reagents used are commercially available unless otherwise specified.

[0047] The composition of the cutting fluid used for the precise manufacture of automobile aluminum wheels of Examples 1-9 is shown in Table 2, wherein, the preparation method of the cutting fluid of Example 1-9 comprises the following steps:

[0048] (1) Add antirust agent A, antirust agent B and some deionized water in proportion, heat to 70-90°C, stir and react at a speed of 300-500rpm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com