Method for calculating thermal efficiency of coal dust and blast furnace gas co-combustion boiler

A technology of blast furnace gas and calculation method, which is applied in calculation, combustion using gaseous fuel and powder fuel, and special data processing applications, etc., can solve the problems of difficulty in measuring and calculating the thermal efficiency of boilers, and it is difficult to accurately obtain the amount of coal fed into the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

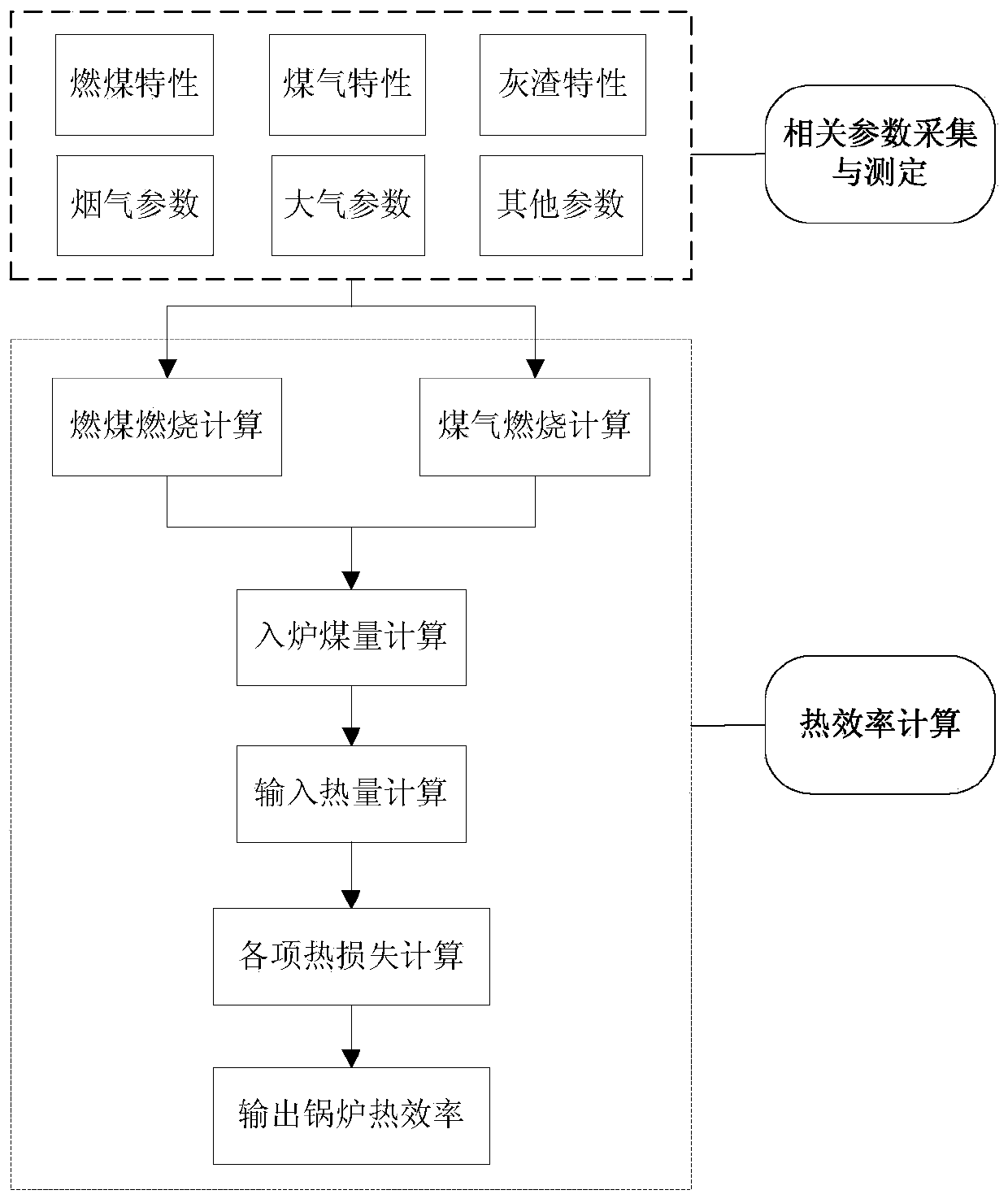

[0102] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

[0103] Such as figure 1 Shown is the thermal efficiency calculation method of the boiler with pulverized coal and blast furnace gas firing. The calculation is as follows:

[0104] First, collect and measure related parameters, and obtain various input parameters of the boiler through instrument measurement and sampling analysis, including:

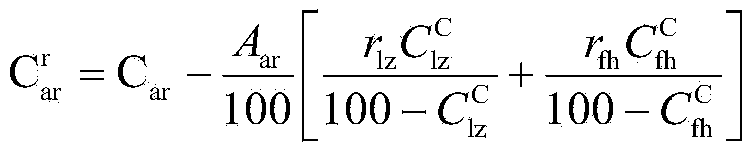

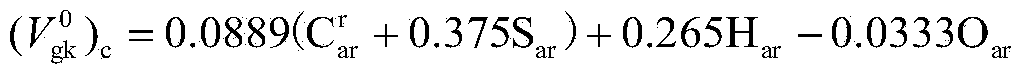

[0105] Sampling and analysis of raw coal and pulverized coal: take raw coal sampling and pulverized coal sampling on the coal feeder and pulverized coal pipe respectively, and then conduct laboratory analysis and calculation processing to obtain the base low calorific value (Q ar,net ) c , Industrial analysis data (including the base ash A ar , Moisture M ar The mass content percentage of the coal), element analysis data (including the mass content percentage of the basic carbon element, hydrogen element, oxygen elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com