A calculation method of gas-fired internal combustion engine power generation and smoke exhaust parameters based on complex working conditions

A technology of gas internal combustion engine and power generation, which is applied in the field of rotating machinery and can solve the problems of gas internal combustion engine power generation, exhaust temperature and exhaust flow difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0221] The present invention will be further described below in conjunction with the accompanying drawings.

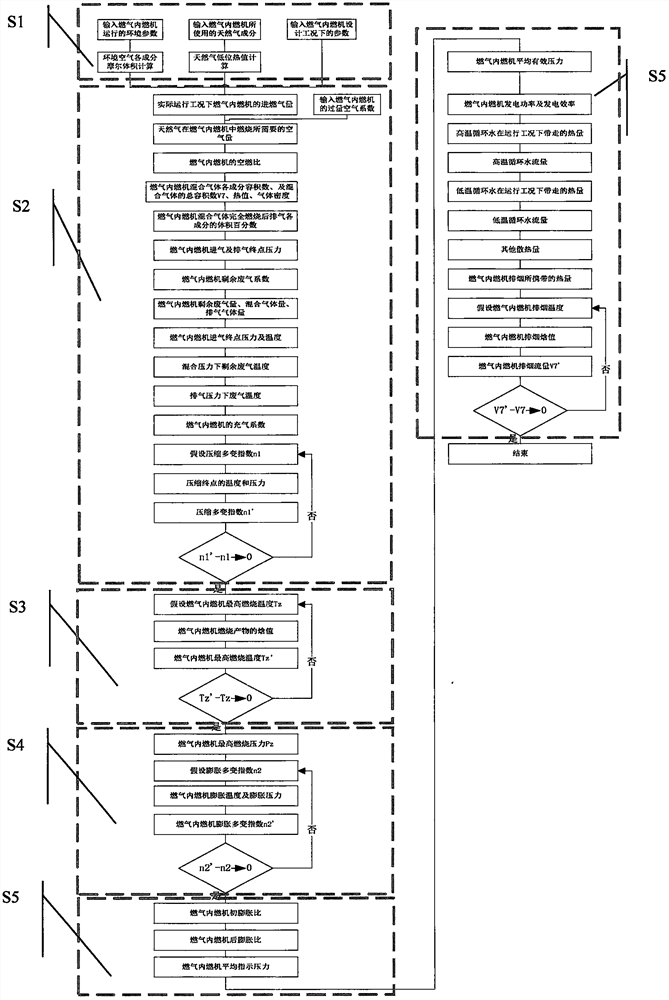

[0222] Such as figure 1 Shown is a calculation method suitable for gas internal combustion engine power generation and smoke exhaust parameters under complex operating conditions. The process includes the collection and measurement of relevant parameters in S1, thermal calculation in S2 compression process, S3 combustion thermal calculation, S4 Thermal calculation of expansion process, calculation of power generation and smoke exhaust parameters of S5 gas internal combustion engine. The calculation is as follows:

[0223] Firstly, the relevant parameters are collected and measured, and various input parameters of the gas turbine are obtained through instrument measurement and sampling analysis, including:

[0224] According to the location of the gas internal combustion engine project, collect the atmospheric pressure, temperature, humidity, altitude and other parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com