Molten blast furnace slag sensible heat recovery method and device

A technology of sensible heat recovery and blast furnace slag, applied in recycling technology, furnace, waste heat treatment and other directions, can solve problems such as environmental pollution and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

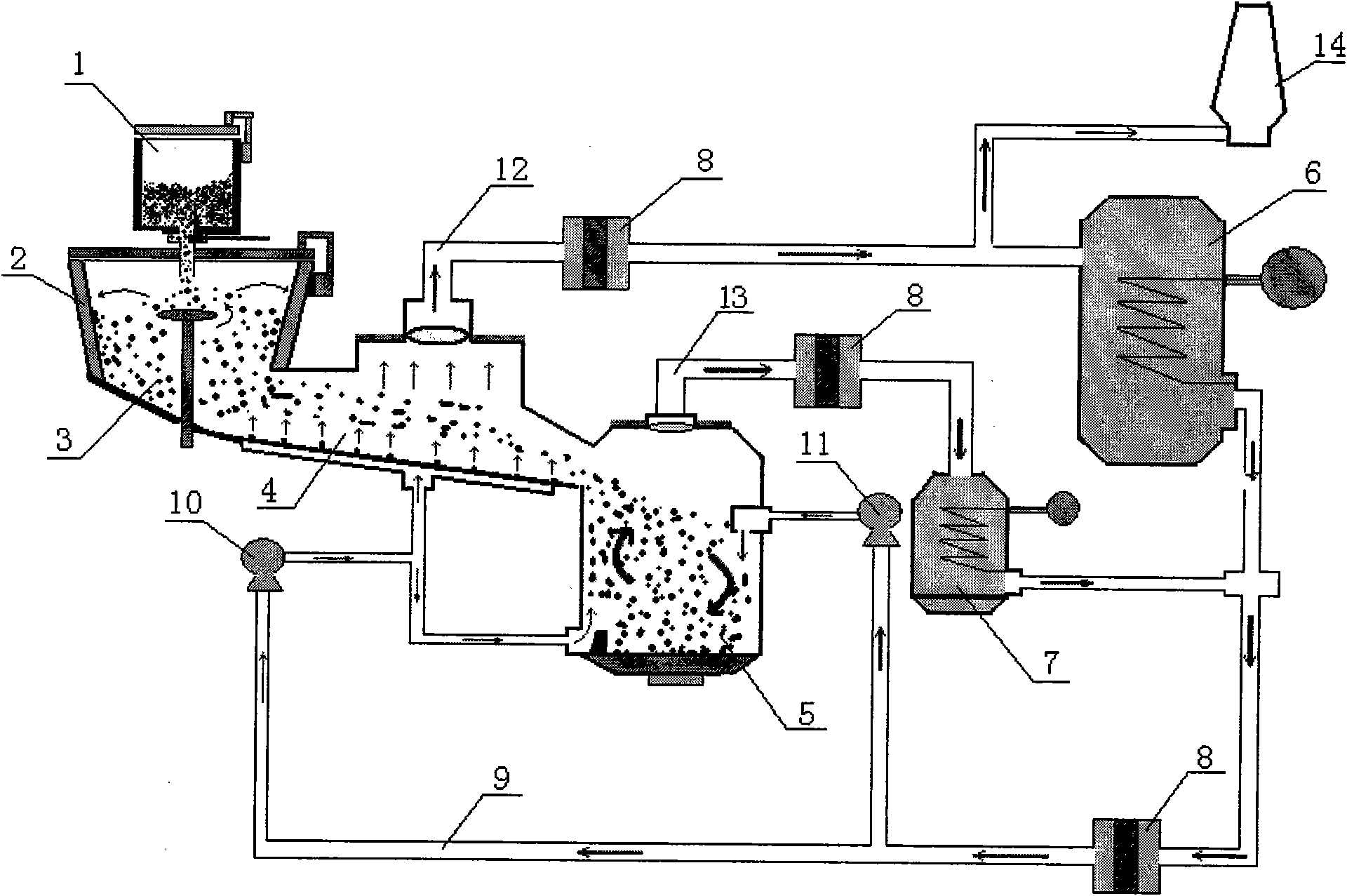

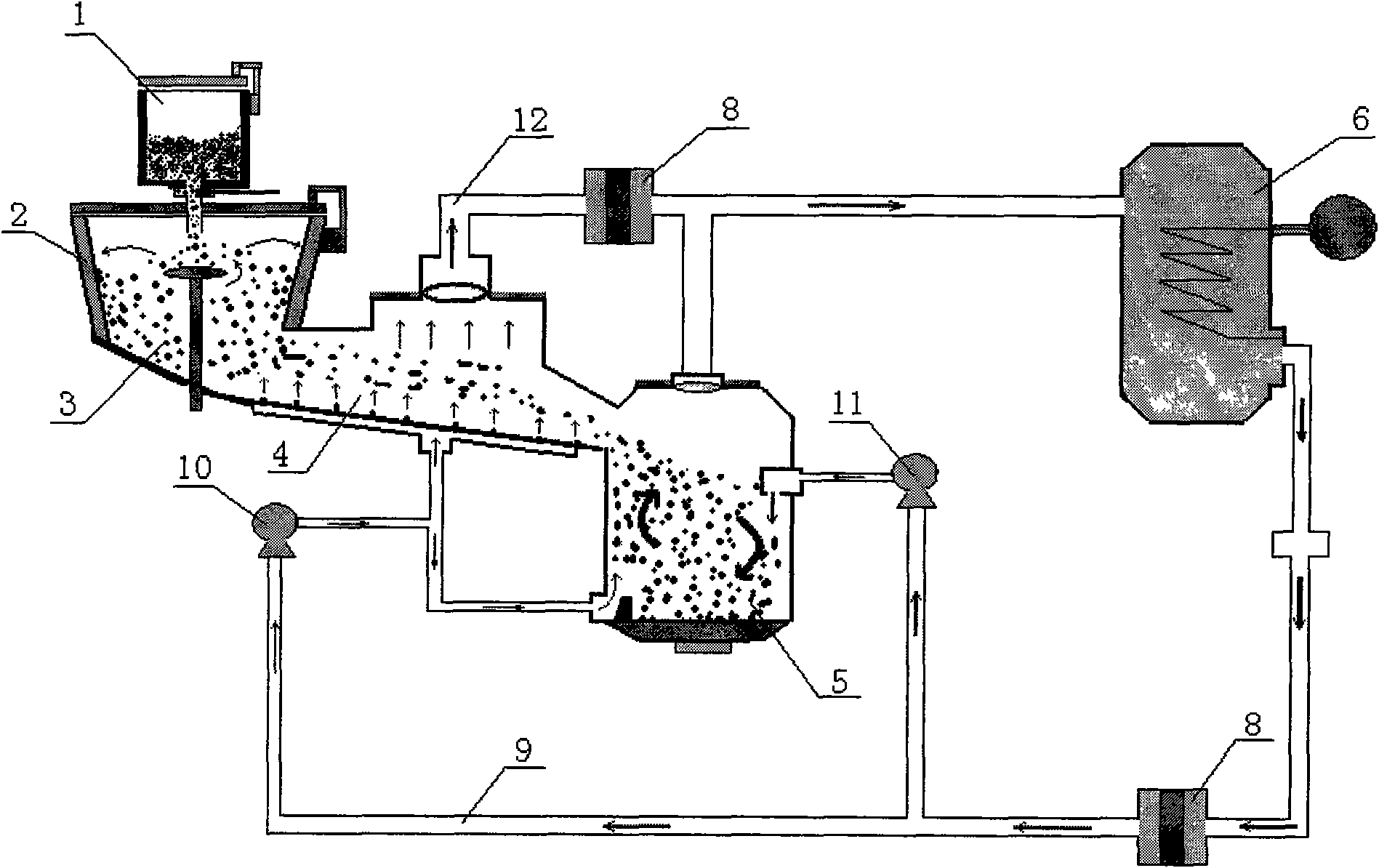

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] Sensible heat recovery method of molten blast furnace slag, the molten blast furnace slag first recovers the heat in the granulator for the first time, then recovers the heat for the second time through the vibrating bed, and finally recovers the heat for the third time in the fluidized bed. The thermal energy is reused or converted into energy in the form of hot wind or power generation, and the steps to realize it are as follows:

[0018] 1) The molten blast furnace slag with a temperature of 1400-1500°C flows into the granulator through the slag tank, and is broken into particles with a diameter of 1-5mm under the centrifugal action of 1800-2000 rpm and hits the water wall of the granulator Cooling and solidification on top to complete the first heat exchange;

[0019] 2) The above-mentioned high-temperature blast furnace slag particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com