Method for treating blast furnace dust

A blast furnace dust removal and treatment method technology, which is applied in the field of metallurgy, can solve the problems of large dosage of flotation reagents, large fluctuations, and low iron powder selection rate, so as to reduce the dosage of flotation reagents, make full use of energy, and improve the selection rate. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: A steel company produces 30,000 tons of blast furnace dust per year, and its main chemical composition is as follows.

[0020] Total iron (%)

Metal iron (%)

Fixed carbon (%)

SiO 2 (%)

CaO(%)

P(%)

S(%)

22-39

20-32

17-30

0.1-1.5

0.1-0.6

0.005-0.05

0.035-0.120

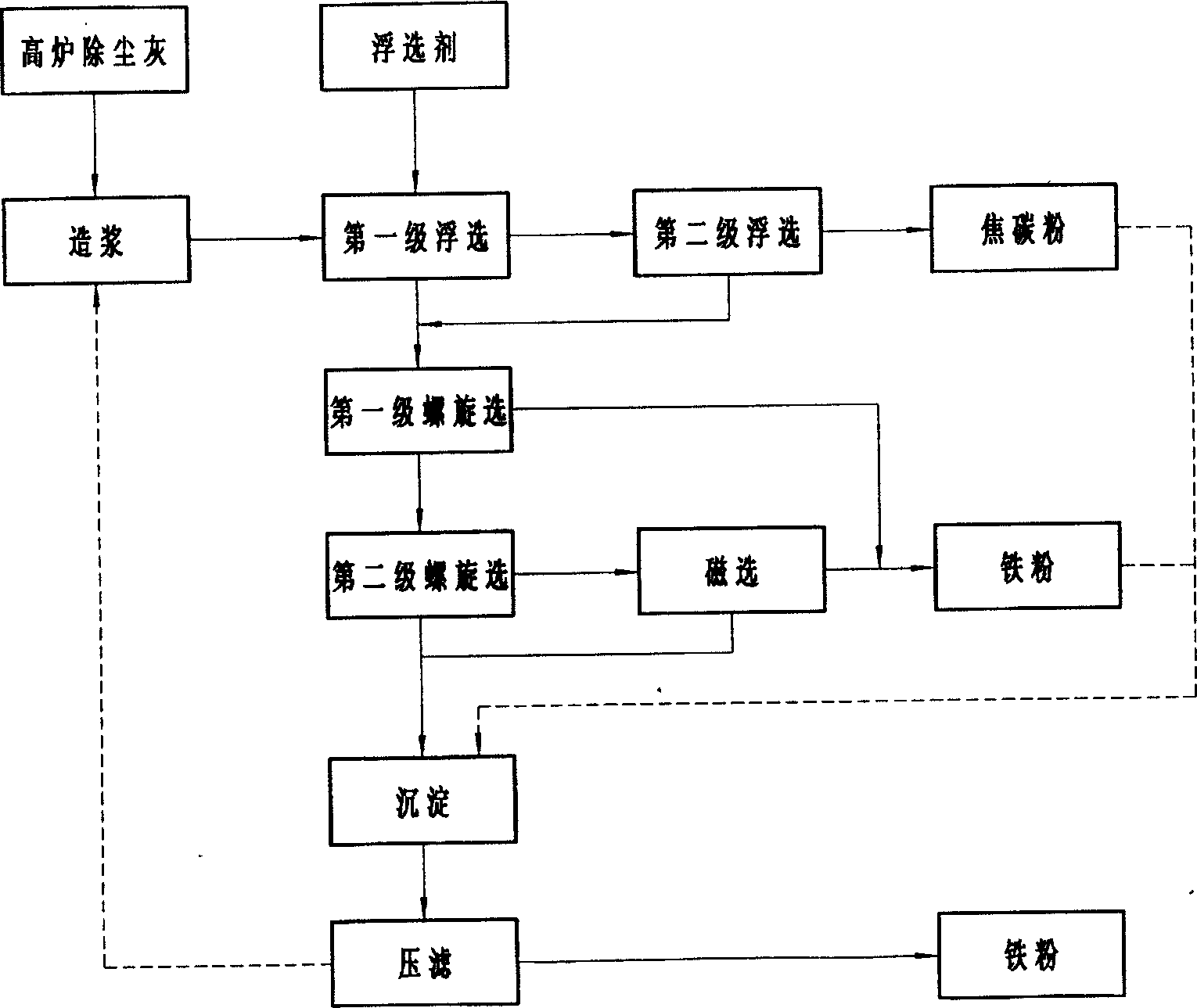

[0021] The processing method of this blast furnace dedusting ash is:

[0022] A. Add water to blast furnace dedusting ash to make slurry, let the slurry mix with flotation agent in the first stage flotation machine for flotation, and separate the slurry with more carbon content from the slurry with more iron powder;

[0023] B. The slurry with more carbon content separated from the first-stage flotation machine is further flotation in the second-stage flotation machine to continue to separate coke powder and further improve the grade of coke powder;

[0024] C. Pump the slurry with more iron powder separated from the first and sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com