Method for directly preparing titanium alloy by titanium concentrate powder

A titanium concentrate and titanium-based technology, applied in the field of metal titanium alloy preparation technology, can solve the problems of failure to effectively solve pollution, high cost, and harsh raw material requirements, so as to achieve easy control of experimental parameters, improve electrolysis efficiency, and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 1.5g of ball-milled ore powder, and press the ore powder into discs under a pressure of 3-6 MPa ( 1.5g),

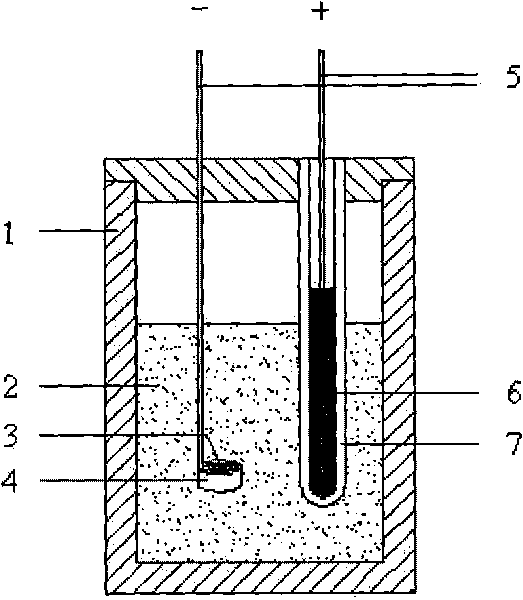

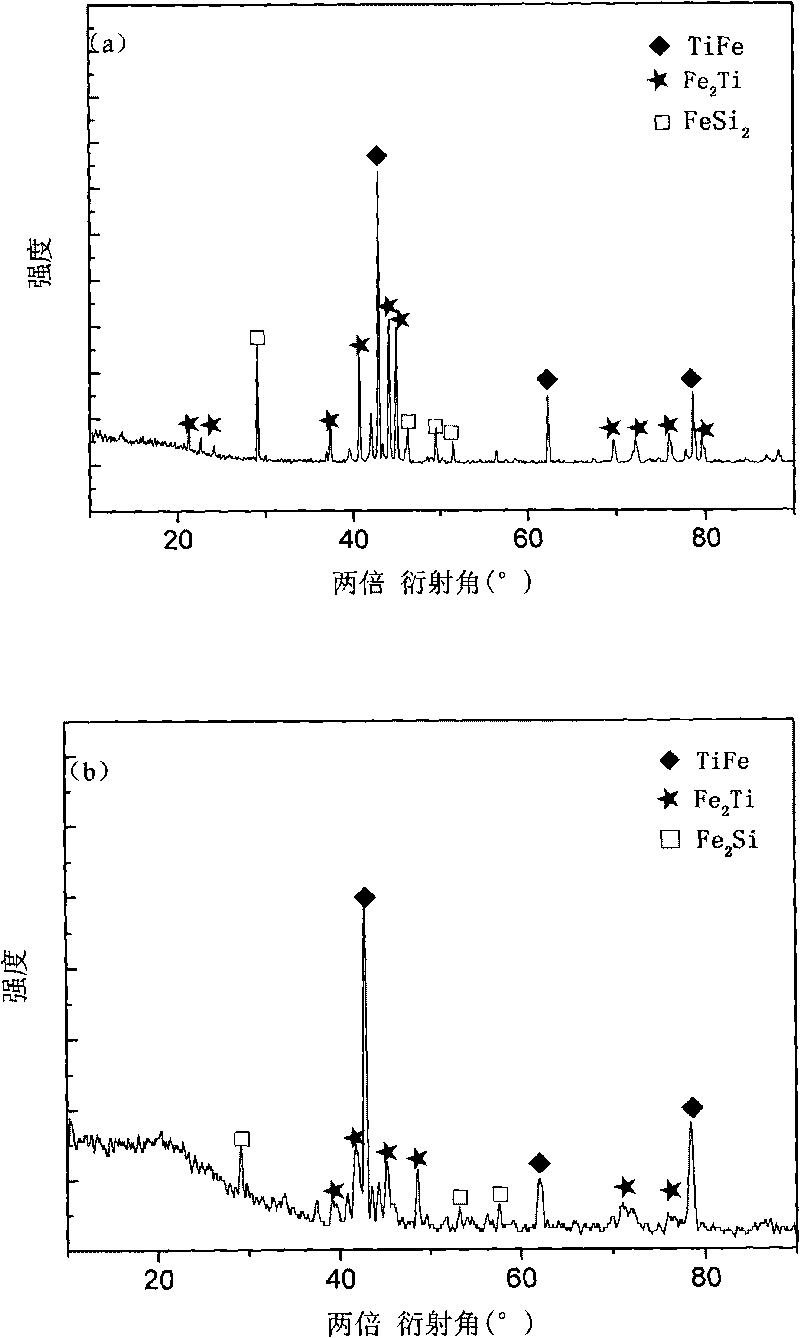

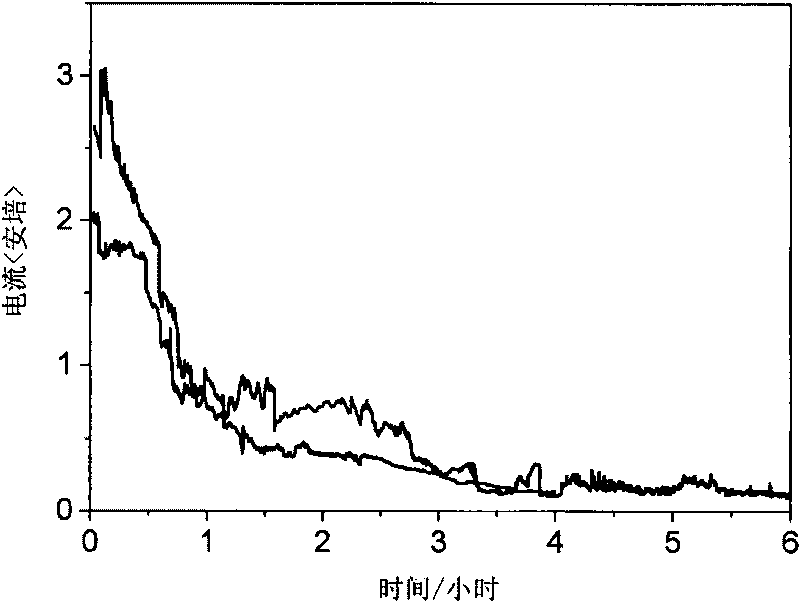

[0032] Then sinter in an oxidizing atmosphere at 1150°C for 2h. Use a molybdenum wire with a diameter of 0.2mm to wind the disc on a molybdenum rod with a diameter of 1.5mm to make the cathode, and the anode is the copper liquid saturated with carbon powder in the YSZ tube (solid oxygen-permeable film), and the CaCl 2 It is a molten salt electrolyte, and the corundum crucible is the reaction vessel. It is electrolyzed in a sealed resistance furnace. The electrolysis temperature is 1100 ° C. The whole electrolysis process is fed with high-purity argon as a protective gas. The electrolysis voltage is 3.5V. After 4 hours of electrolysis, the current drops to A very low value maintains the level, and the electrolysis is completed. After cooling down, take out the cathode and wash it with water to remove CaCl 2 Molten salt, low temperature drying to obtain rel...

Embodiment 2

[0034] Weigh 1.5g of ball-milled ore powder, and press the ore powder into discs under a pressure of 3-6 MPa ( 1.5g), and then sintered in an oxidizing atmosphere at 1150°C for 2h. see figure 1 , put the mineral powder sintered sheet directly in a small stainless steel crucible, the whole small stainless steel crucible is submerged in the molten salt of the electrolytic cell, and the small stainless steel crucible is drawn out by a molybdenum wire as the cathode, and the anode is saturated with carbon powder in the YSZ tube (solid oxygen permeable membrane) copper liquid to CaCl 2 It is a molten salt electrolyte, and the corundum crucible is the reaction vessel. It is electrolyzed in a sealed resistance furnace. The electrolysis temperature is 1100 ° C. The whole electrolysis process is fed with high-purity argon as a protective gas. The electrolysis voltage is 3.5V. After 6 hours of electrolysis, the current drops to A very low value maintains the level, and the electrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com