Boron carbide composite material and preparation method thereof

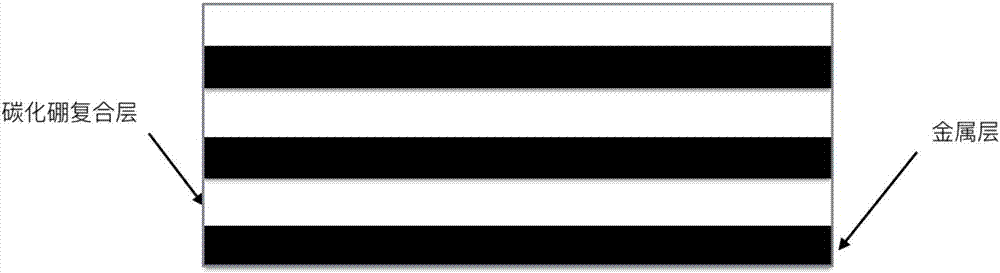

A technology of composite materials and boron carbide, which is applied in the field of layered boron carbide metal composite materials and its preparation, can solve the problems of high sintering temperature, large performance dispersion, and difficulty in preparing complex shapes, so as to improve interface bonding strength and good Toughness, effect of reducing defect sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

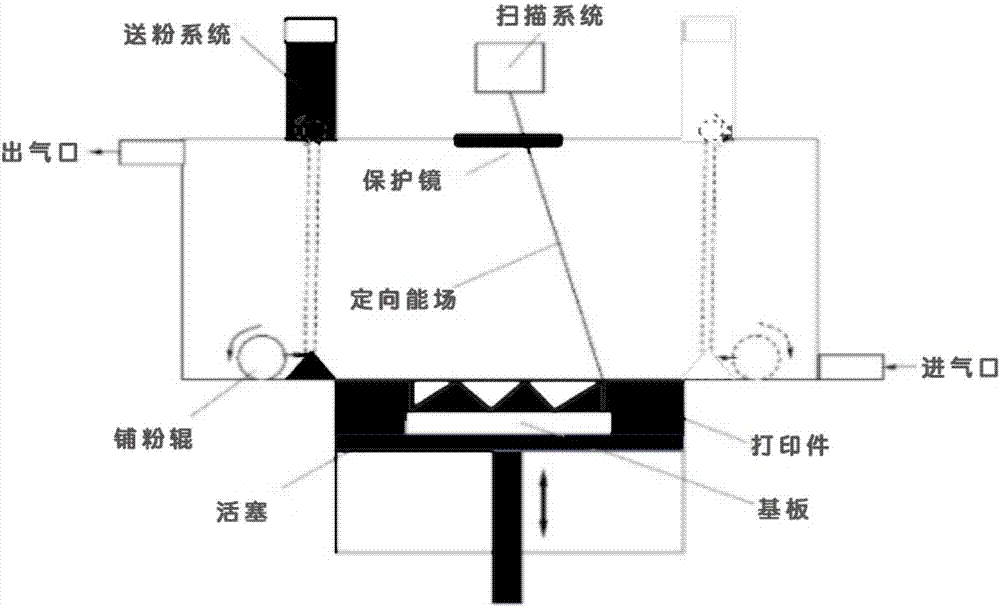

Method used

Image

Examples

Embodiment 1

[0027] A boron carbide composite material is characterized in that the raw materials include the following components by weight percentage: 30% of 0.2 μm boron carbide powder, 25% of 0.2 μm silicon powder and 25% of 0.2 μm carbon powder and 20% of 2μm aluminum powder.

[0028] The boron carbide powder has a cubic boron carbide content >98%.

[0029] The silicon powder is spherical silicon powder, and the content of impurity elements should be less than 1wt%.

[0030] The carbon powder is spherical graphite powder.

[0031] The aluminum powder is spherical aluminum powder.

[0032] The preparation method of the present embodiment is characterized in that it comprises the following steps:

[0033] Step 1, weighing 30% of 0.2 μm boron carbide powder, 25% of 0.2 μm silicon powder, 25% of 0.2 μm carbon powder and 20% of 2 μm aluminum powder;

[0034] Step 2, take out 70% of the total amount of aluminum powder for use, and prepare the mixed powder A by wet ball milling the remai...

Embodiment 2

[0038] A boron carbide composite material is characterized in that the raw materials include the following components by weight percentage: 40% of 2 μm boron carbide powder, 10% of 4 μm silicon powder and 5% of 2 μm carbon powder and 10% of 3 μm aluminum powder and 35% of 10μm lead powder.

[0039] The boron carbide powder has a cubic boron carbide content >98%.

[0040] The silicon powder is spherical silicon powder, and the content of impurity elements should be less than 1wt%.

[0041] The carbon powder is spherical amorphous carbon powder.

[0042] Both the aluminum powder and the lead powder are spherical powders.

[0043] The preparation method of the present embodiment is characterized in that it comprises the following steps:

[0044] Step 1, weighing 40% of 2 μm boron carbide powder, 10% of 4 μm silicon powder, 5% of 2 μm carbon powder, 10% of 3 μm aluminum powder and 35% of 10 μm lead powder;

[0045] Step 2, take out 70% of the total amount of aluminum powder an...

Embodiment 3

[0049] A boron carbide composite material is characterized in that the raw materials include the following components by weight percentage: 40% 200 μm boron carbide powder, 10% 200 μm silicon powder, 10% 200 μm carbon powder and 40% 200 μm lead powder .

[0050] The boron carbide powder has a cubic boron carbide content >98%.

[0051] The silicon powder is spherical silicon powder, and the content of impurity elements should be less than 1wt%.

[0052] The carbon powder is spherical graphite powder.

[0053] The lead powder is spherical lead powder.

[0054] The preparation method of the present embodiment is characterized in that it comprises the following steps:

[0055] Step 1, weighing 40% of 200 μm boron carbide powder, 10% of 200 μm silicon powder, 10% of 200 μm carbon powder and 40% of 200 μm lead powder;

[0056] Step 2, take out 50% of the total amount of the lead powder for use, and prepare the mixed powder A with the remaining lead powder and the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com