Soil improvement agent taking sugar refinery sugarcane boiler carbon dust as raw material as well as preparation method and application of soil improvement agent

A soil improver, sugarcane technology, applied in the direction of application, organic fertilizer, fertilizer mixture, etc., to achieve the effect of coordinating soil micro-ecological environment, increasing activity and quantity, and improving soil aggregate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

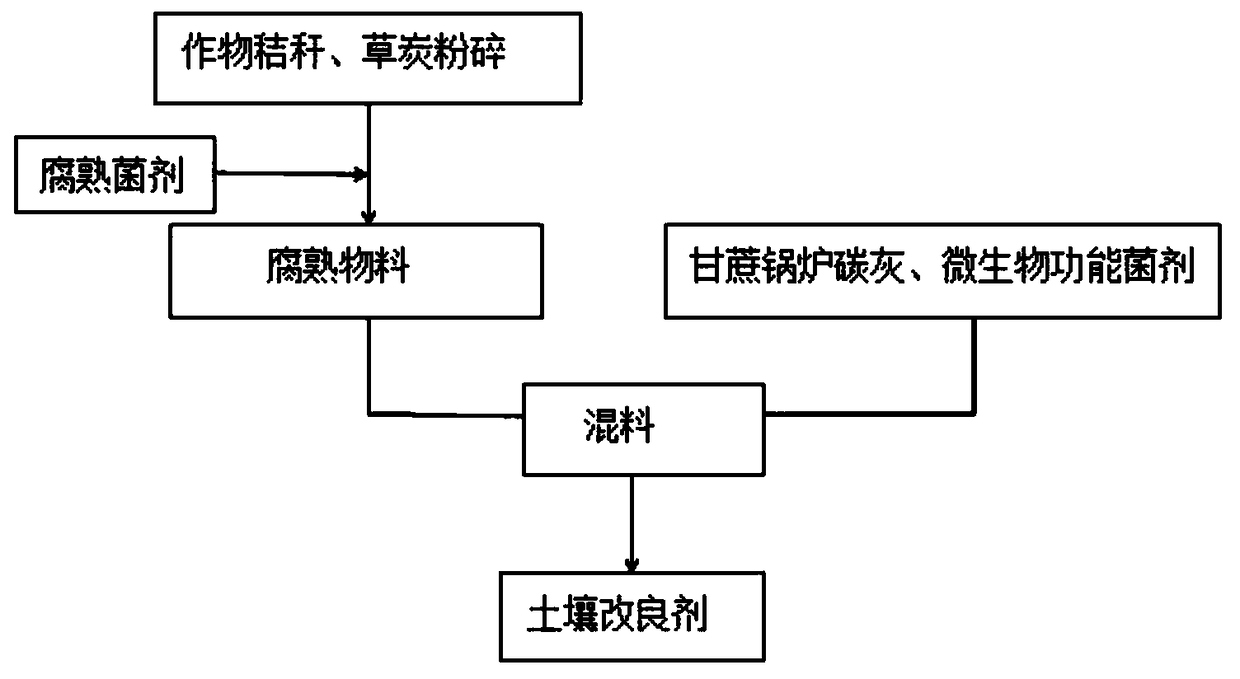

[0031] The preparation method comprises the following steps:

[0032] 1. After crushing crop straw and peat, pass through a 60-80 mesh sieve, add decomposing bacteria agent for fermentation, and ferment at a high temperature of 65 degrees for 20 days. The fermented materials should be turned every 1-3 days to fully decompose Finally, the material produces a large amount of mycelium without pungent smell, and the fermentation ends when the temperature in the pile drops to room temperature, and the decomposed material is obtained, dried, and the water content (quality) reaches about 30%, and it is ready for use.

[0033] 2. Add the decomposed material to the carbon ash of the sugarcane boiler, then add the beneficial functional microbial agent, stir and mix evenly, spray and granulate at a low temperature of 60-80°C, the particle size is 3mm-5mm, and dry at a temperature below 80°C , that is, a soil conditioner with living beneficial microorganisms.

[0034] Crop stalks are one...

Embodiment 1

[0038] The invention discloses a method for preparing a soil conditioner using sugar cane boiler carbon ash as a raw material, comprising the following raw materials in parts by weight: 600 parts of sugar cane boiler carbon ash, 300 parts of crop straw, 5 parts of biological bacteria agent and 20 parts of peat.

[0039] After the crop straw and peat are crushed, a decomposing bacterial agent is added to ferment, and the fermentation is carried out at a high temperature of 65 degrees for 20 days.

[0040] The decomposed material is added to the carbon ash of the sugarcane boiler, and then the beneficial functional microbial bacterial agent is added, after being stirred and mixed, sprayed, dried and granulated to obtain a soil conditioner with living beneficial microorganisms.

[0041] The crop stalks are corn stalks, rape stalks, and rice stalks; the fermented materials are turned every 1-3 days. The decomposing bacteria agent and beneficial functional microbial agent are provi...

Embodiment 2

[0043] The invention discloses a preparation method of a soil conditioner using sugar cane boiler carbon ash as raw material, comprising the following raw materials in parts by weight: 700 parts of sugar cane boiler carbon ash, 400 parts of crop straw, 6 parts of biological bacteria agent and 35 parts of peat.

[0044] After the crop straw and peat are crushed, a decomposing bacterial agent is added to ferment, and the fermentation is carried out at a high temperature of 65 degrees for 20 days.

[0045] The decomposed material is added to the carbon ash of the sugarcane boiler, and then the beneficial functional microbial bacterial agent is added, after being stirred and mixed, sprayed, dried and granulated to obtain a soil conditioner with living beneficial microorganisms.

[0046] The crop stalks are corn stalks, rape stalks, and rice stalks; the fermented materials are turned every 1-3 days. The decomposing bacteria agent and beneficial functional microbial agent are provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com