Anthraquinone lithium battery positive pole and preparation method thereof

A battery positive electrode and anthraquinone lithium technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of increased production costs and complicated operation steps, and achieve the effects of improved production efficiency, simple preparation steps, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

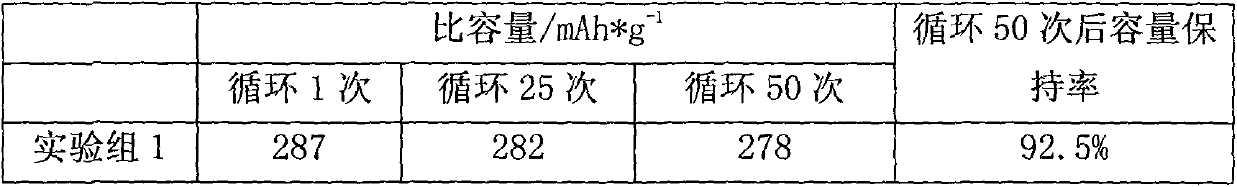

Embodiment 1

[0023] Experimental group 1: Weigh 5g of acetylene black powder and 10g of zinc oxide powder, put them into a small grinder, and grind for 1 hour at the speed of the crushing head at 10000r / min. Pass the ground acetylene black powder and zinc oxide powder through a 1000-mesh sieve.

[0024] Weigh 5g of 6-amino-1,3-dihydroxyanthraquinone, 1.67g of sieved acetylene black powder, zinc oxide powder, and 10g of DMF and stir at room temperature for 1h with a paint mixer at a speed of 600r / min. After mixing the above mixture with polyvinylidene fluoride at a mass ratio of 10:1, apply it on an aluminum foil with a doctor blade, and dry it to obtain a positive electrode sheet. In the glove box with lithium as the negative electrode, with 1mol / L LiPF 6 / Ethyl carbonate + diethyl carbonate as the electrolyte, Cellgard2000 polypropylene film as the diaphragm, assembled into a battery, and tested the charge and discharge performance.

[0025] Experimental group 2: Weigh 5g of 6-amino-1,...

Embodiment 2

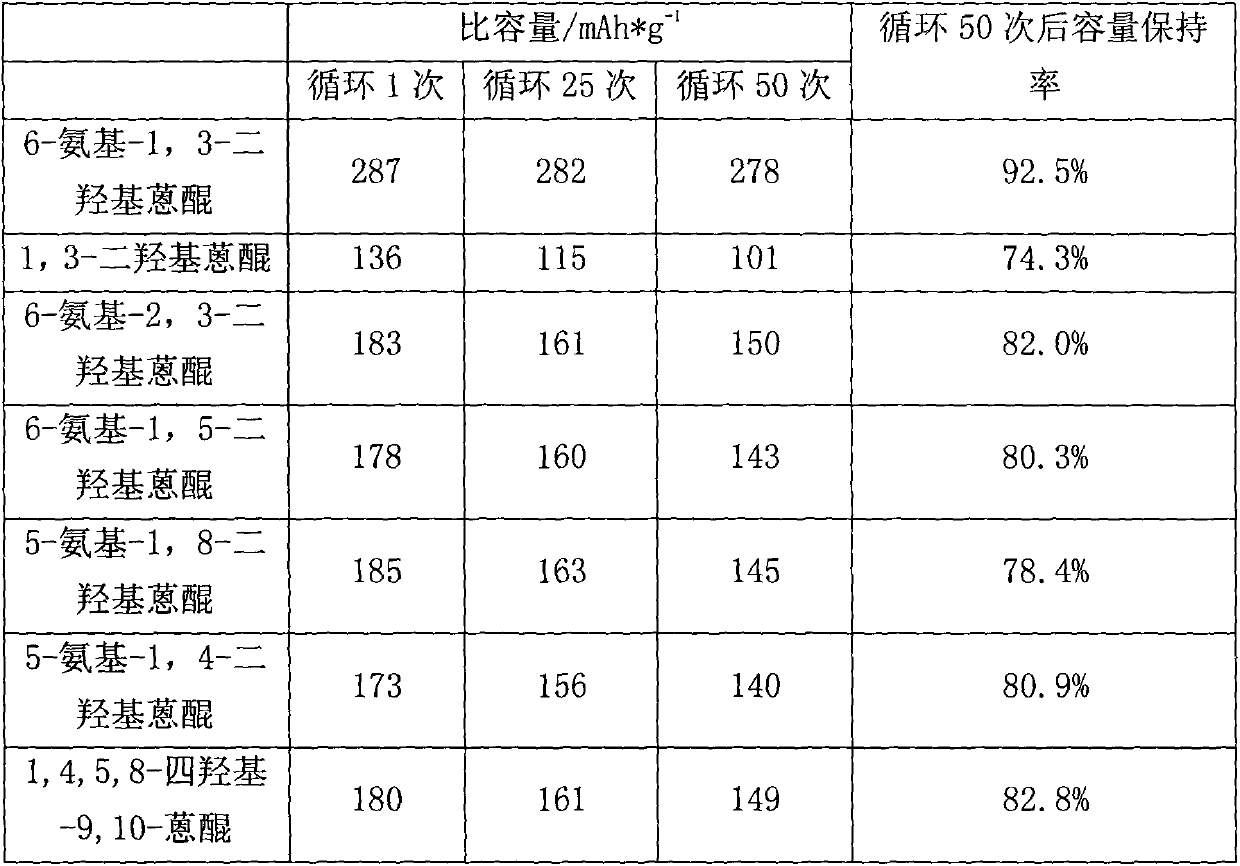

[0030] Example 2: Put acetylene black powder and zinc oxide powder into a small grinder, and grind for 2 hours at the speed of the crushing head at 10000 r / min. Pass the ground acetylene black powder and zinc oxide powder through a 1000-mesh sieve. Weigh 5 g of anthraquinone derivatives (specifically as shown in Table 2), 1.67 g of sieved acetylene black, and 10 g of DMF, and stir at room temperature for 1 h with a paint mixer at a speed of 600 r / min. The mixture was mixed with polyvinylidene fluoride at a mass ratio of 10:1, coated on aluminum foil with a doctor blade, and dried to obtain a positive electrode sheet. In the glove box with lithium as the negative electrode, with 1mol / L LiPF 6 / Ethyl carbonate + diethyl carbonate as the electrolyte, Cellgard2000 polypropylene film as the diaphragm, assembled into a battery, and tested the charge and discharge performance. The specific results are shown in Table 2 below:

[0031] Table 2: Specific capacity and capacity retenti...

Embodiment 3

[0034] Example 3: Put acetylene black powder and zinc oxide powder into a small grinder, and grind for 0.5 h at the speed of the crushing head at 10000 r / mmin. Pass the ground powder through a 1000 mesh sieve. Take four parts of 5g of 6-amino-1,3-dihydroxyanthraquinone respectively, each part is mixed with acetylene black, zinc oxide and DMF after sieving respectively in a certain proportion (concrete results are shown in Table 3), Stir with a paint mixer, stir at room temperature for 1 h, and rotate at 600 r / min to obtain a mixture. Weigh a certain amount of the mixture, mix it with polyvinylidene fluoride in a certain proportion at a mass ratio of 10:1, apply it on an aluminum foil with a spatula, and dry it to obtain a positive electrode sheet. Afterwards, battery assembly and charge and discharge performance tests were carried out, and the steps were the same as those in Example 1.

[0035] Table 3 Specific capacity and capacity retention of different ratios of 6-amino-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com