Shading ring processing method and shading ring

A processing method and technology for shading circles, applied in the processing of shading circles and the field of shading circles, can solve problems such as glare, halo and ghosting, and achieve the effect of avoiding glare, improving quality and ensuring shooting effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

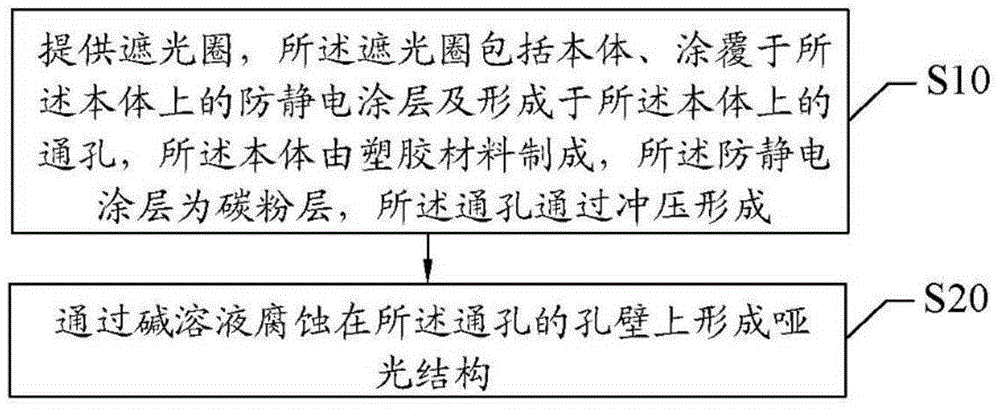

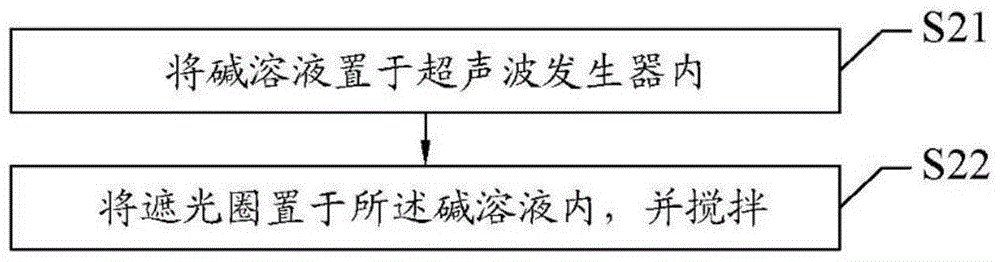

[0025] The invention provides a processing method of a shading ring, referring to figure 1 , in one embodiment, the processing method of the shading ring includes the following steps:

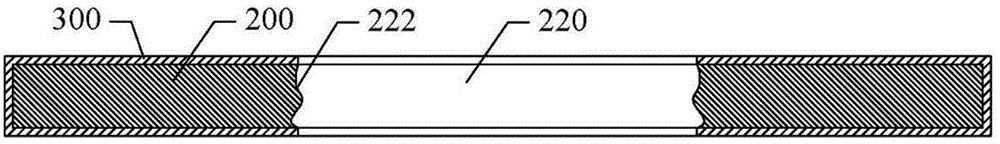

[0026] Step S10, providing a shading ring, the shading ring includes a main body, an antistatic coating coated on the main body, and a through hole formed on the main body, the main body is made of plastic material, and the antistatic The coating is a layer of carbon powder, and the through holes are formed by punching.

[0027] Specifically, in this embodiment, the thickness of the shading ring is 0.025 mm, the diameter of the through hole is 2.14 mm, and the body is made of polyethylene terephthalate.

[0028] Because the manufacturing method of the light-shielding ring is to form the main body first, then apply an antistatic coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com