Preparation method of acrylic resin-based glass fiber reinforced plastic

A technology of acrylic resin and glass fiber, which is applied in the field of resin-based glass fiber reinforced plastics and its preparation, can solve problems such as potential safety hazards, and achieve the effect of high flame retardancy and high comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

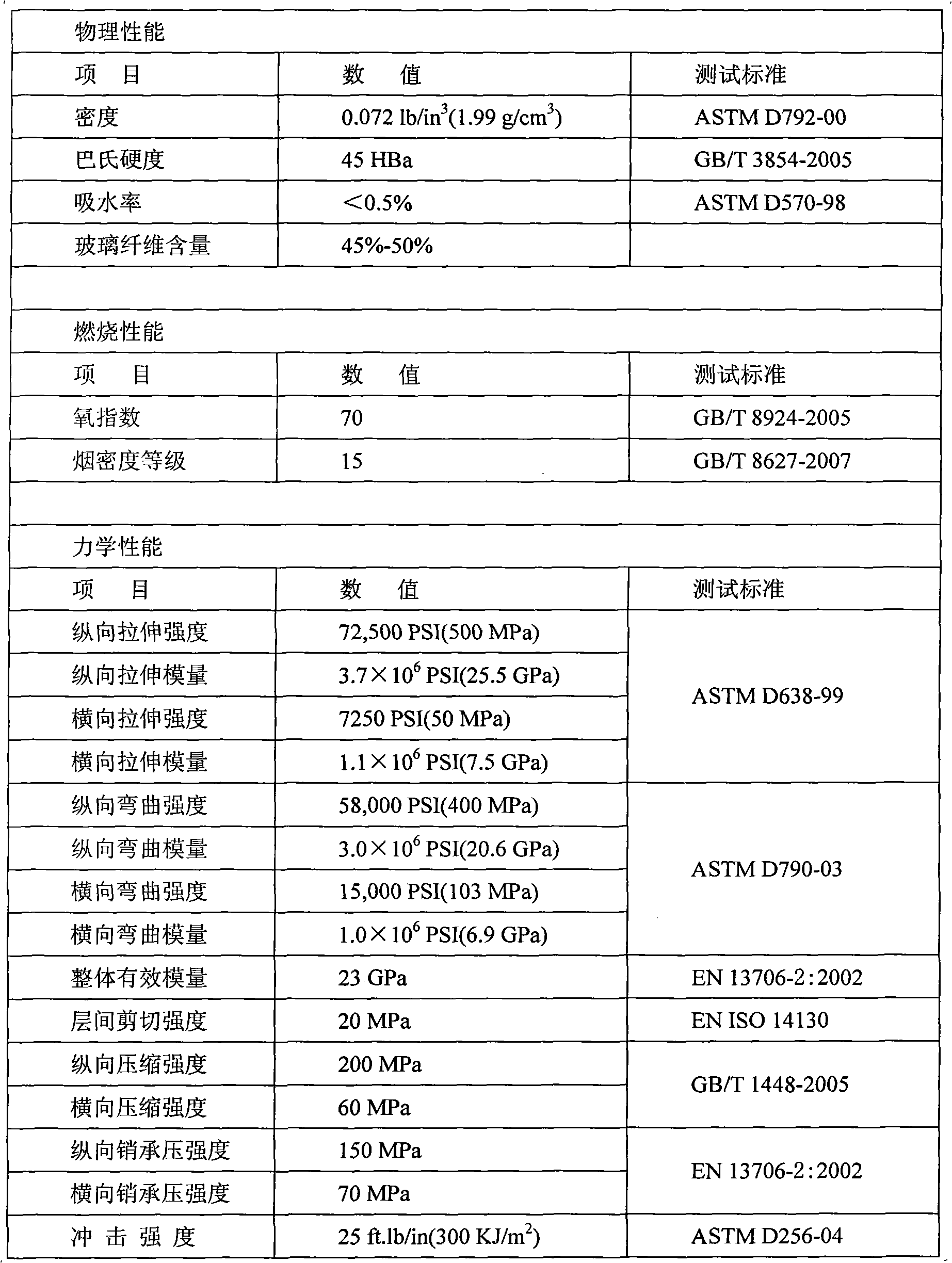

[0033] Polyurethane-modified acrylic resin-based glass fiber reinforced plastics are prepared into glass fiber reinforced plastics (GFRP) with high flame retardancy and high comprehensive mechanical properties. The raw material components, content (relative to the weight percentage of 1212 resin adopted) and the pultrusion process parameters of the GFRP are as follows:

[0034] Composition example

1

2

3

4

5

6

7

8

9

10

Acrylic

1

1

1

1

1

1

1

1

1

1

Powdered Aluminum Hydroxide

1.6

1.5

1.7

1.8

2

2

2

1.5

2

2

toner

0.1

0.2

0.3

0.2

0.3

0.05

0.05

0.05

0.1

0.2

0.01

0.01

0.001

0.01

0.005

0.01

0.01

0.01

0.01

0.02

0.01

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com