Tail gas treatment system for through which

A technology of tail gas treatment and cracking furnace, which is applied in the direction of combustion technology mitigation, climate sustainability, and reduction of greenhouse gases. It can solve the problems of ineffective removal of carbon dust particles and reduce the high temperature of tail gas, so as to reduce carbon dioxide emissions and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

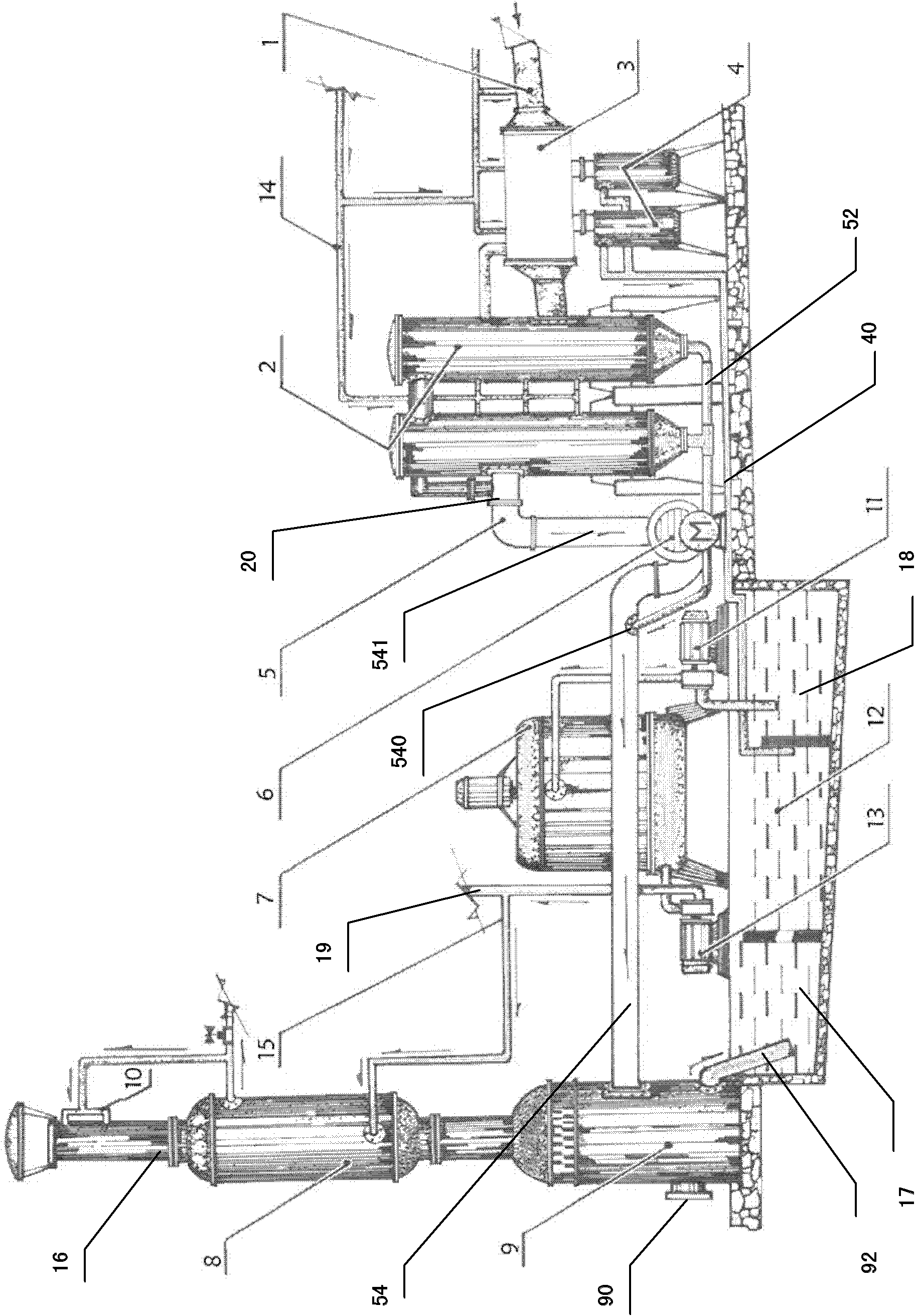

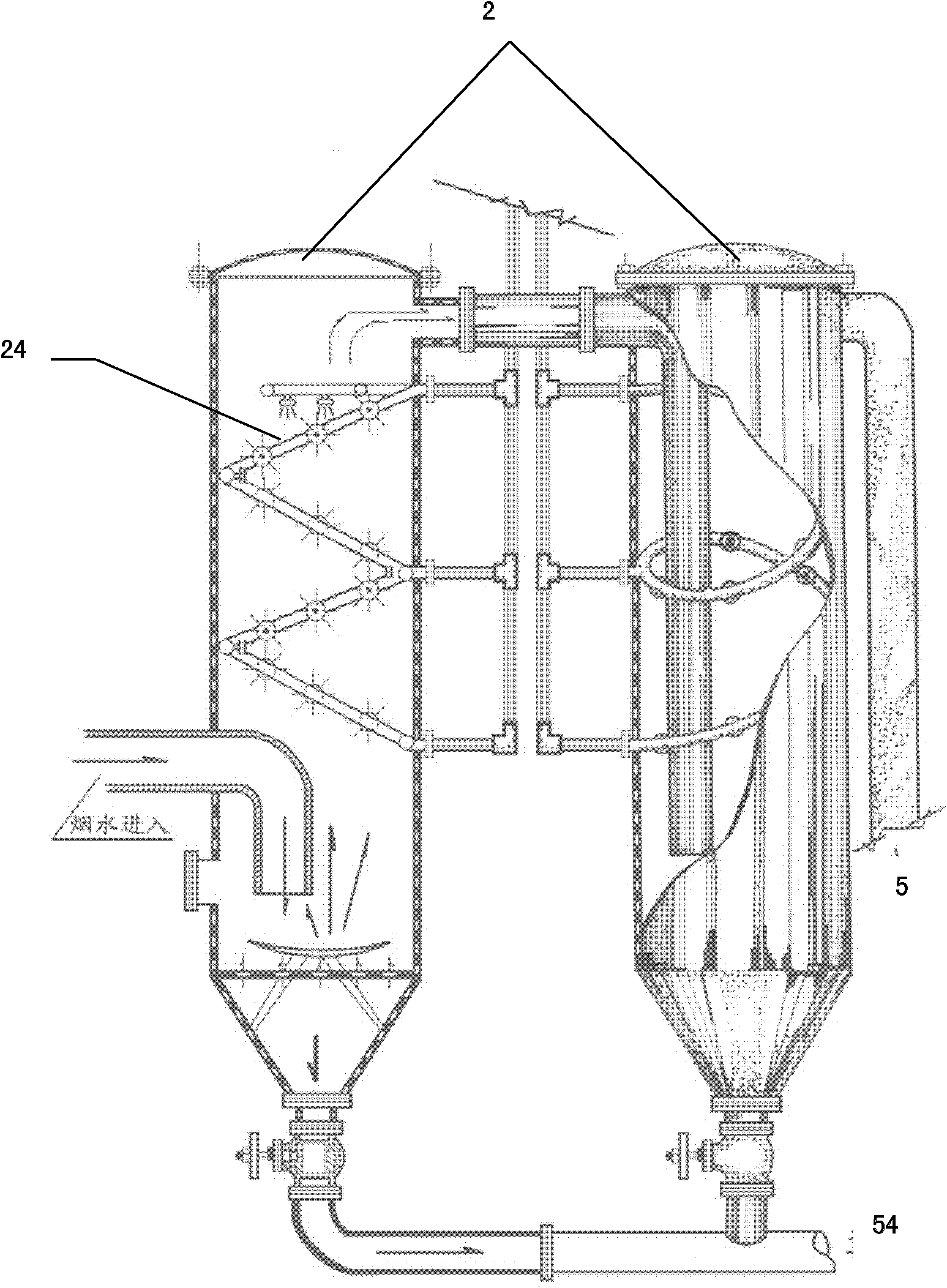

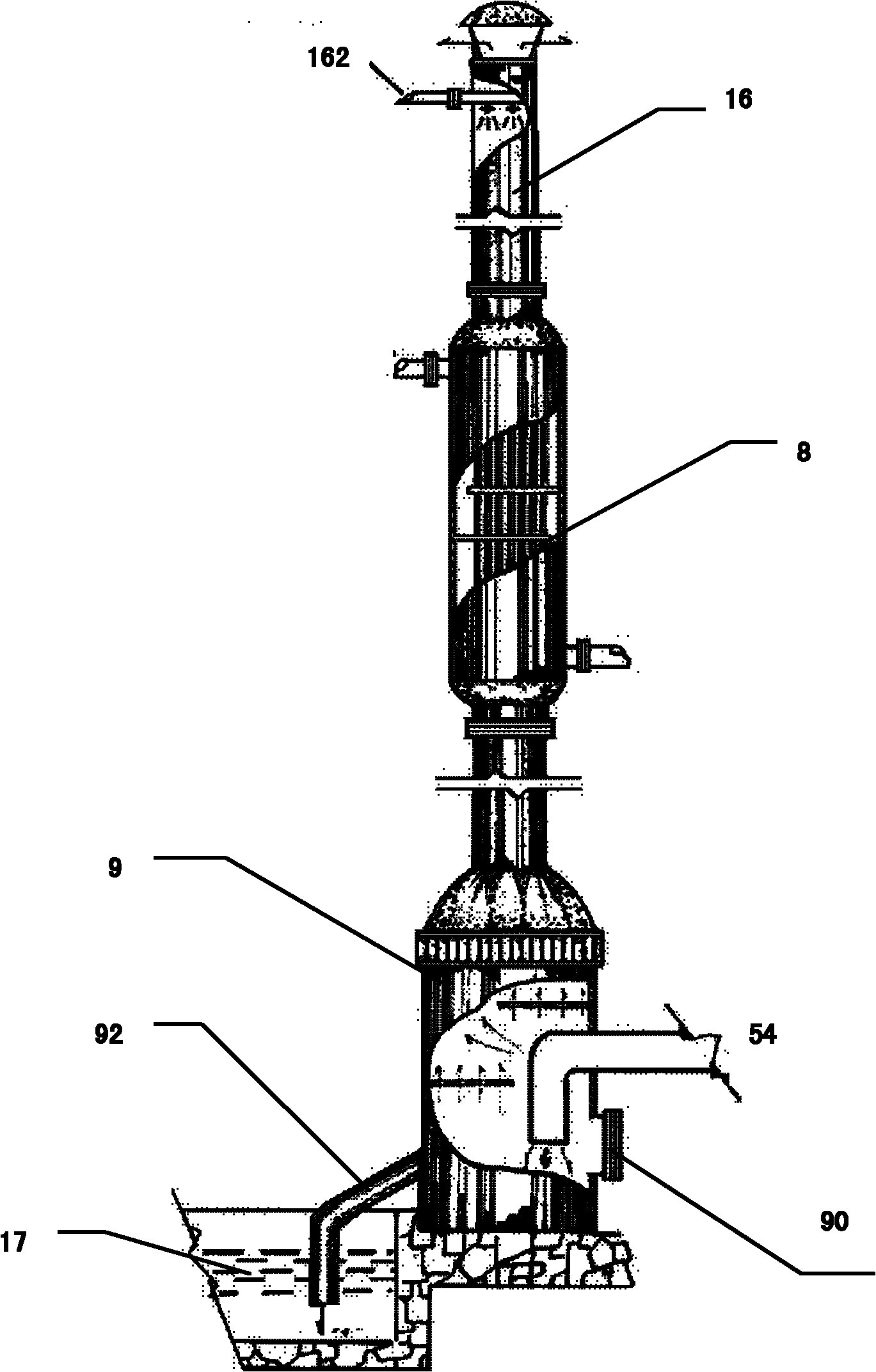

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] like Figure 1-3 As shown, this fuel cracking furnace tail gas treatment system includes a carbon dust filter system connected to the cracking furnace, and the carbon dust filter system includes a connecting pipe 1 communicating with the cracking furnace, and the connecting pipe 1 is a square pipe , the other end of which is connected to the hot air water buffer chamber 3, and two or more layers of multi-layer water curtain sprays are arranged in the connecting pipeline, and two layers of water curtain sprays are arranged in the buffer chamber 3, connected from a square The hot gas entering the pipeline weakens the destructive thermal impact force caused by the flue gas (water) driving the carbon particles in the flue gas under the action of multi-layer water curtain spraying and buffer chamber; at the same time, a carbon residue filter 4 is installed at the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com