Preparation method of high-porosity alumina porous ceramics

A technology of porous ceramics and high porosity, used in ceramic products, other household appliances, household appliances, etc., can solve problems such as limitation of scope, and achieve the effect of improving material strength, high porosity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

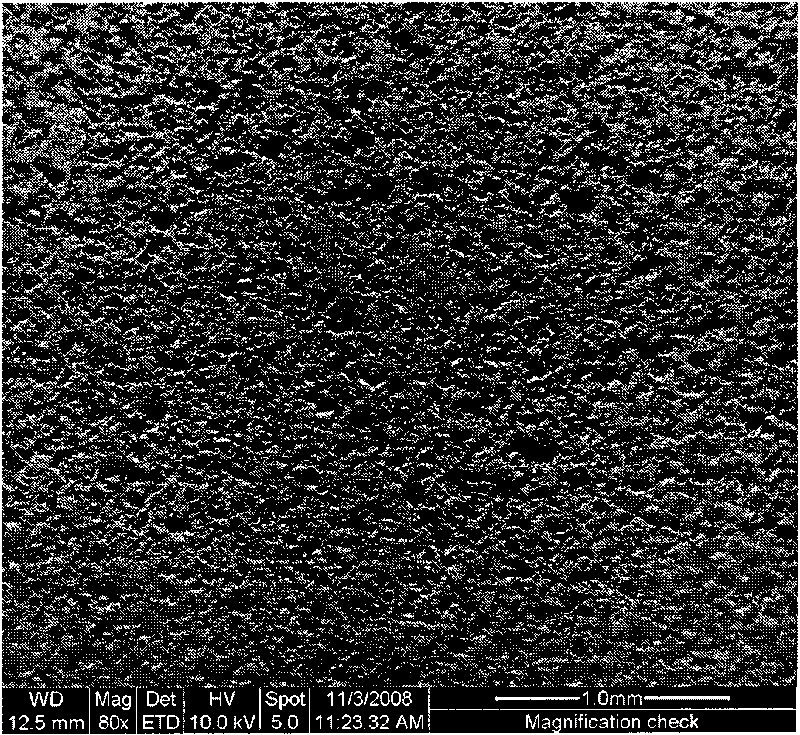

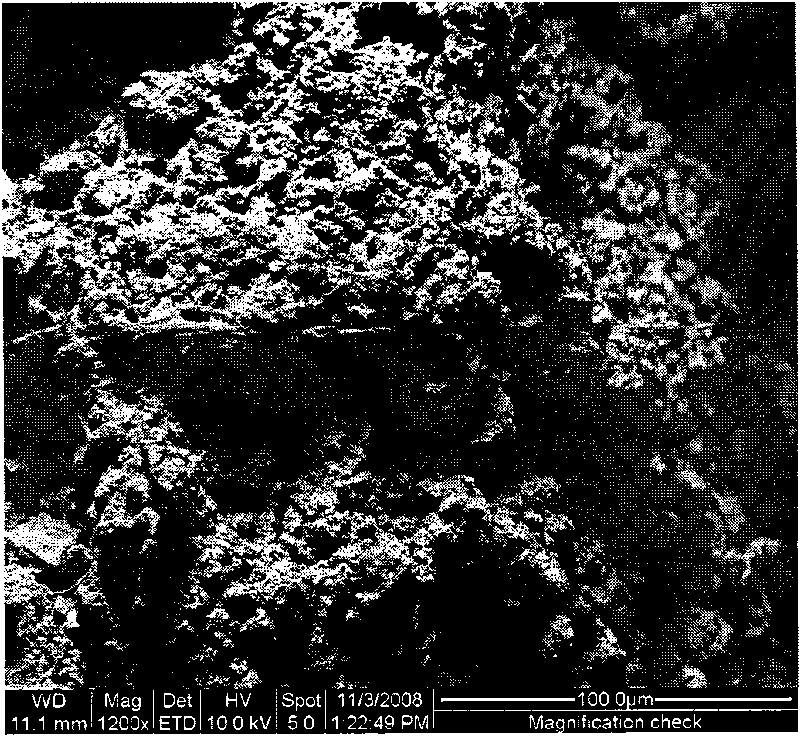

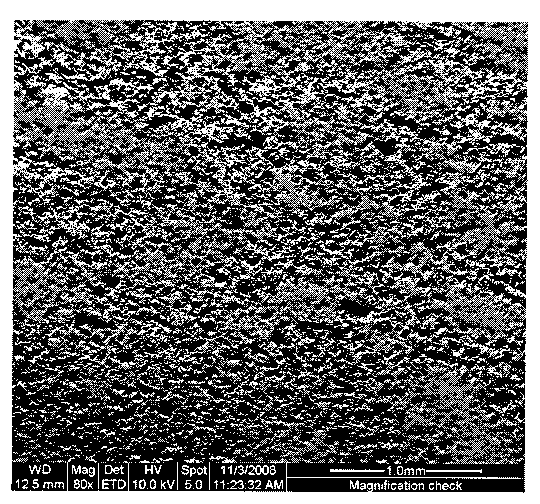

Image

Examples

Embodiment 1

[0024] A preparation method of high-porosity alumina porous ceramics, the method steps are as follows,

[0025] (1) with MgCl 2 ·6H 2 O and stearic acid were used as raw materials, heated in a 78°C water bath with magnetic stirring for 20min to fully react to obtain a light yellow transparent sol. Stop heating and stirring, and naturally cool to room temperature to obtain a gel. The gel was heated at 70°C Dried for 24 hours to obtain magnesium stearate gel, i.e. magnesium xerogel;

[0026] (2) Weighing raw materials, the raw materials for preparing high-porosity alumina porous ceramics are by weight percentage, alumina powder: 74%, carbon powder: 15%, ethyl cellulose: 10%, magnesium xerogel: 1% .

[0027] (3) Mix the carbon powder and ethyl cellulose fully in advance for 20 minutes, grind the magnesium xerogel for 20 minutes before use, put the alumina powder, mixed carbon powder, ethyl cellulose, and ground magnesium xerogel into the ball mill After 2 hours of ball millin...

Embodiment 2

[0030] A preparation method of high-porosity alumina porous ceramics, the method steps are as follows,

[0031] (1) with MgCl 2 ·6H 2 O and stearic acid were used as raw materials, heated in a 90°C water bath with magnetic stirring for 40min to make it fully react, and a light yellow transparent sol was obtained. Stop heating and stirring, and naturally cool to room temperature to obtain a gel. Dried for 48 hours to obtain magnesium stearate gel, i.e. magnesium xerogel;

[0032] (2) with ZrOCl·8H 2 O, Y (NO 3 ) 2 ·8H 2 O, oxalic acid as raw material, heated in a 70°C water bath with magnetic stirring for 15min, the solution turned from milky white to light blue, and continued to stir for 2h to obtain a transparent light blue gel, moved to an open petri dish, and aged in a 70°C water bath After washing for 2 hours, washing with water and alcohol twice, and drying at 60°C for 14 hours, zirconium oxalate gel, namely zirconium xerogel, was obtained;

[0033] (3) Weighing ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com