No-lead RE doped sealing glass powder with low smelting point and its production process

A rare earth element and sealing glass technology, applied in the field of P2O5-SnO-ZnO lead-free low-melting glass powder, can solve the problems of difficult preparation, high sealing temperature of sealing glass powder, poor chemical stability, etc., and reduce expansion Coefficient, increase production efficiency, improve the effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

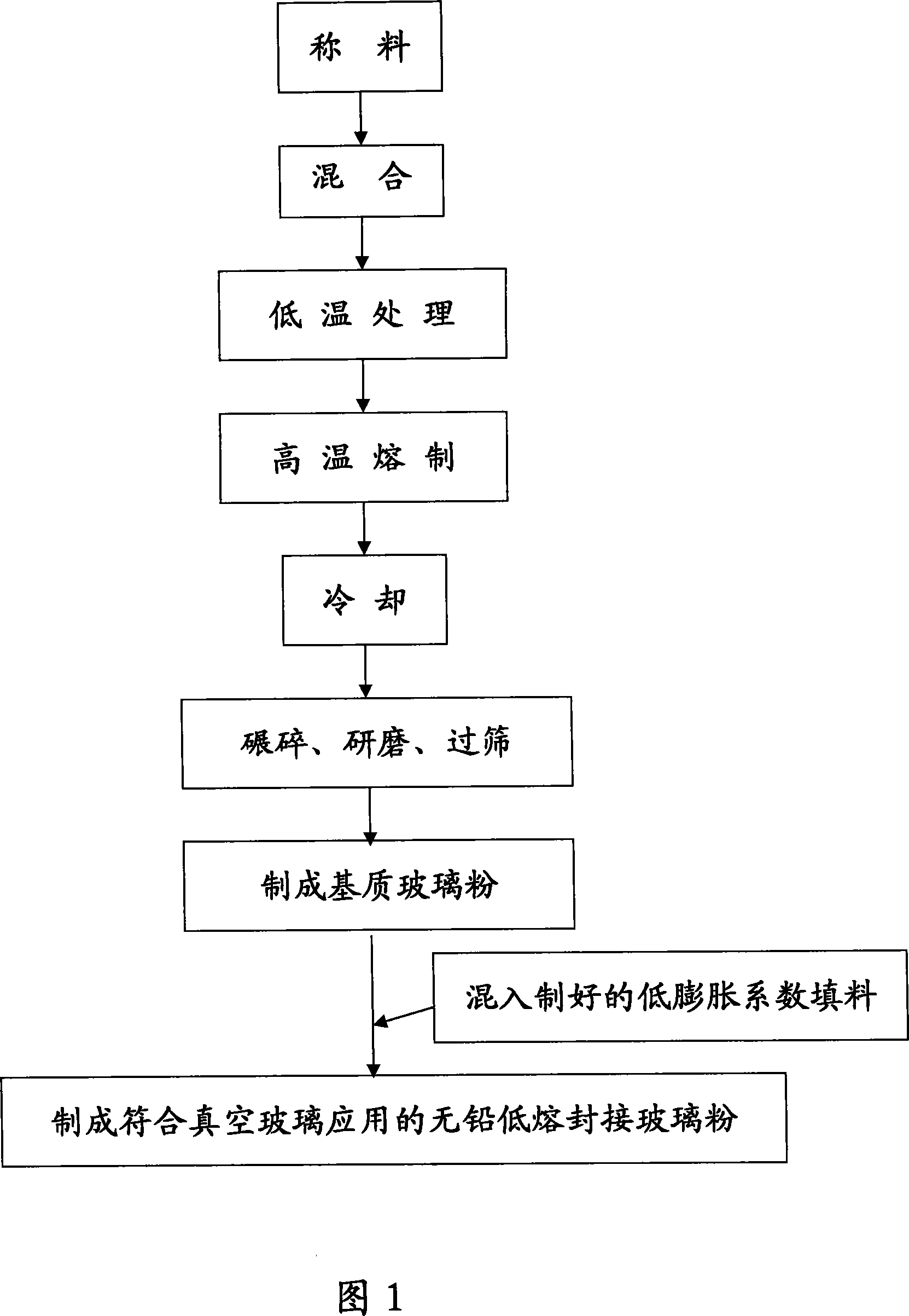

Method used

Image

Examples

Embodiment 1

[0034] Step 1: calculate according to the composition of example 1 in table 1 and take by weighing raw material compound (gram), P 2 o 5 38.5, SnO 70.0, ZnO 8.5, MgO 10.0, B 2 o 3 25.0, Al 2 o 3 5.0, Sb 2 o 3 20.0, Li 2 O 12.0, Na 2 O 15.0, K 2 O 10.0, CaO 8.0, SrO 6.0, BaO 16.0, Fe 2 o 3 8.0, WO 3 5.0, La 2 o 3 1.0, Y 2 o 3 , 8.0, Nd 2 o 3 6.0.

[0035] Step 2: Mix the above-mentioned weighed raw materials evenly, dry them at 280°C, grind and pulverize (about 200 mesh) after treatment, and mix 0.3 g of carbon powder as a reducing agent (0.1 g of the total amount of raw materials in step 1 can be selected. ~0.3wt%), melted at 1100°C for 2 hours, cooled on an iron plate, then crushed, ground, and sieved (200 mesh to 220 mesh) to form glass powder.

[0036] Step 3: using three types or four types of quartz glass prefabricated rods to prepare quartz glass powder fillers, grinding, pulverizing, and sieving (200 mesh to 220 mesh) to obtain fillers.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com