Lead-free bismuthate glass powder used for bonding electronic ceramics

A technology of lead-free bismuth salt and electronic ceramics, which is applied in the chemical industry, can solve the problems of unsuitable sealing, unfavorable industrial application, and failure to meet the requirements of lead-free, and achieves good air tightness, wide application range, Effect of low sealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

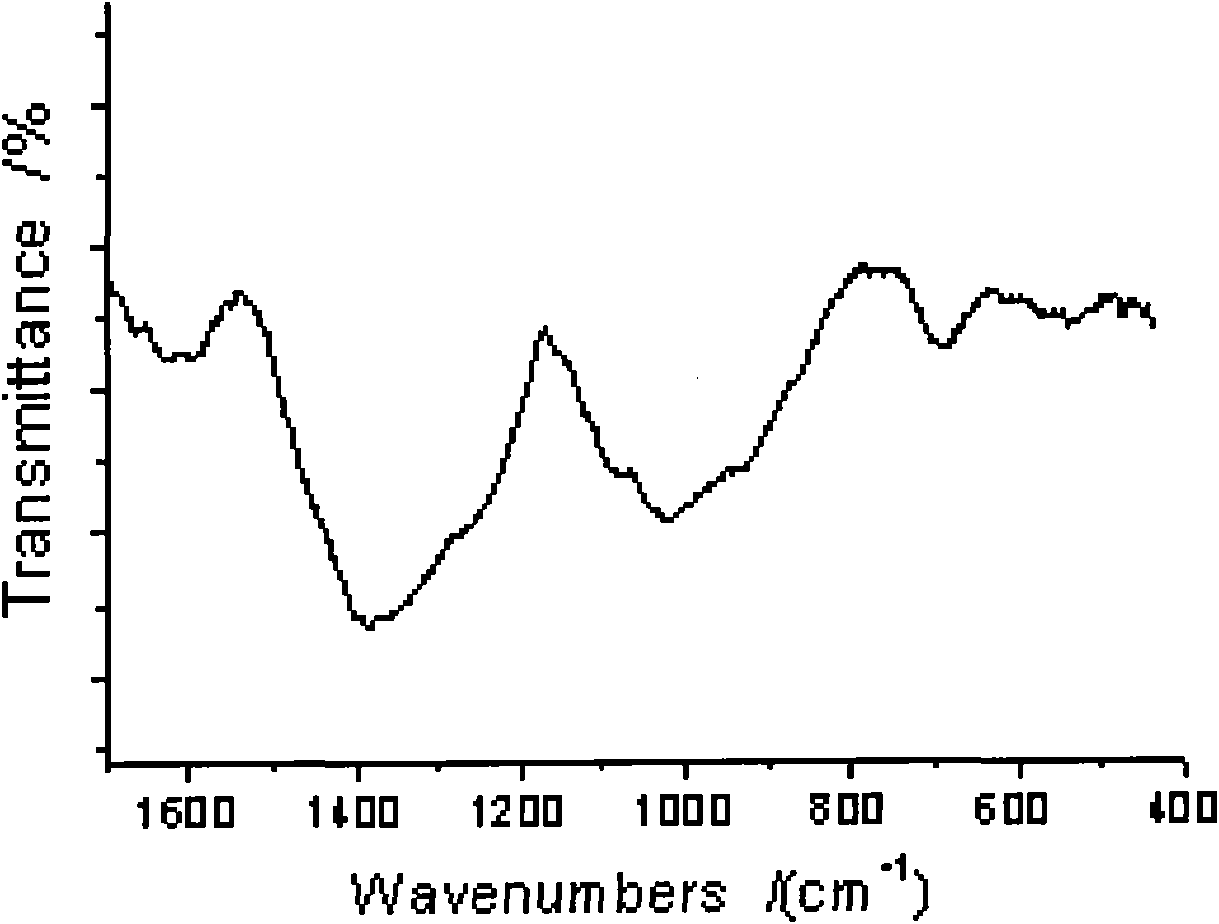

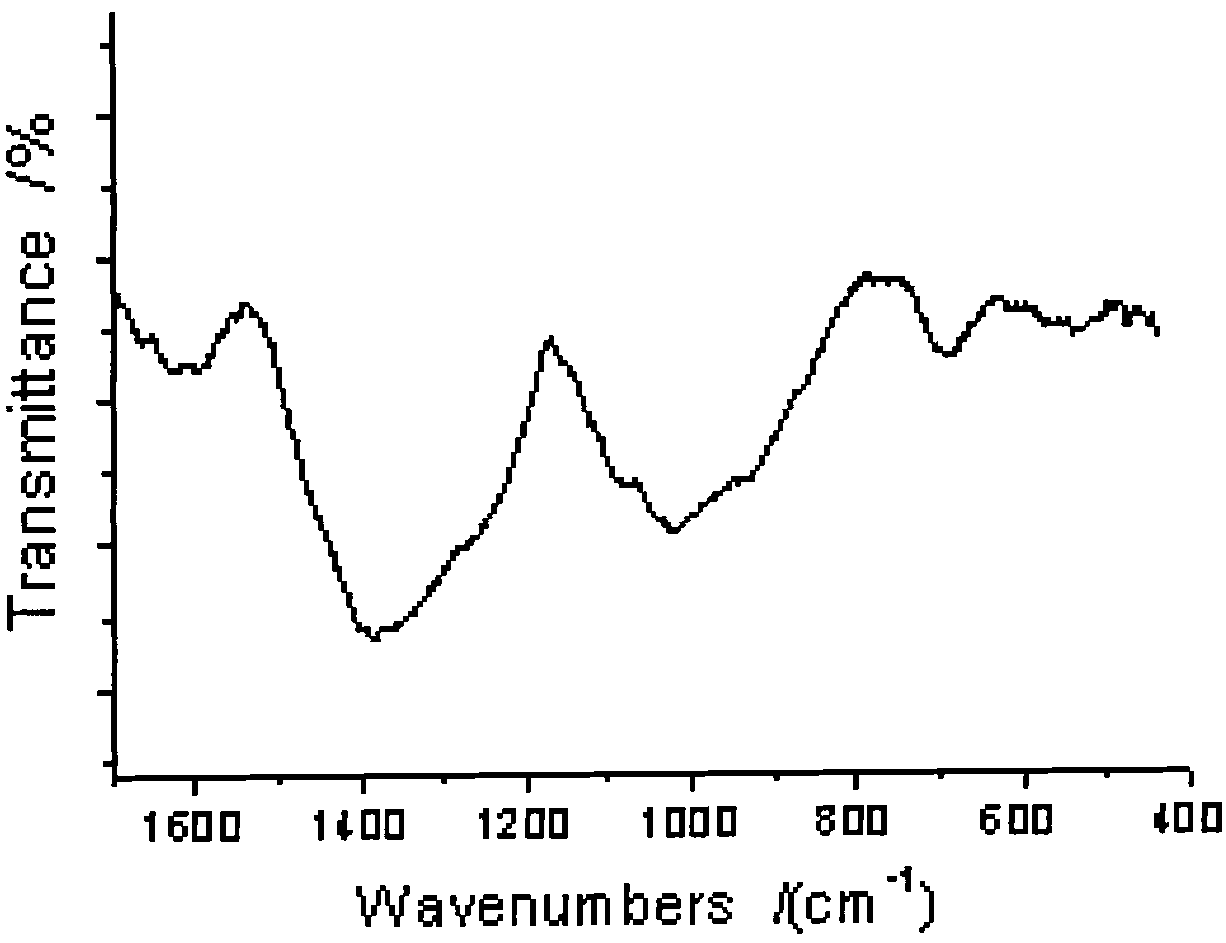

Image

Examples

Embodiment 1

[0058] 1. The composition of raw materials in molar percentage is:

[0059] Bi 2 o 3 74%, B 2 o 3 6%, ZnO 5%, Al 2 o 3 3%, MgO 3%, V 2 o 5 2%, Li 2 O is 3%, WO 3 2%, P 2 o 5 is 1%, and SrO is 1%.

[0060] 2. Preparation method:

[0061] (1) take each raw material according to the weight percentage of each component;

[0062] (2) Fully mix the raw materials taken;

[0063] (3) Put the mixed mixture into a crucible, then put it into an electric furnace with a furnace temperature of 1150° C., and keep it warm for 70 minutes;

[0064] (4) Pour the melted glass liquid into cold water for water quenching;

[0065] (5) The glass after water quenching is dried, and put into ball mill ball mill;

[0066] (6) Sieve, test and pack the ball-milled glass powder.

[0067] 3. Test results:

[0068] Expansion coefficient: 82×10 -7 / °C (300°C) Sintering temperature: 500°C

[0069] Volume resistivity: >10 12 Ω·cm Sintering time: 40min

[0070] Particle size range: 1~10μm W...

Embodiment 2

[0073] 1. The composition of raw materials in molar percentage is:

[0074] Bi 2 o 3 66%, B 2 o 3 11%, ZnO 7%, Al 2 o 3 3%, MgO 5%, V 2 o 5 1%, Li 2 O is 2%, WO 3 2%, P 2 o 5 2% for SrO and 1% for SrO.

[0075] Two, preparation method: with embodiment 1.

[0076] 3. Test results:

[0077] Expansion coefficient: 77×10 -7 / °C (300°C) Sintering temperature: 530°C

[0078] Volume resistivity: >10 12 Ω·cm Sintering time: 40min

[0079] Particle size range: 1~10μm Water resistance: good

[0080] Crystal type: non-crystalline Fluidity: good

Embodiment 3

[0082] 1. The composition of raw materials in molar percentage is:

[0083] Bi 2 o 3 70%, B 2 o 3 10%, ZnO 6%, Al 2 o 3 4%, MgO 3%, V 2 o 5 2%, Li 2 O is 1%, WO 3 1%, P 2 o 5 2% for SrO and 1% for SrO.

[0084] Two, preparation method: with embodiment 1.

[0085] 3. Test results:

[0086] Expansion coefficient: 75×10 -7 / °C (300°C) Sintering temperature: 520°C

[0087] Volume resistivity: >10 12 Ω·cm Sintering time: 40min

[0088] Particle size range: 1~10μm Water resistance: good

[0089] Crystal type: amorphous Fluidity: good

[0090] It is worth noting that the present invention can provide a matching lead-free bismuth salt glass frit used for bonding electronic ceramics to each other according to the characteristics of the specific sealing material and the specific requirements for temperature and expansion coefficient. The method is to select different components to form the glass so as to obtain a variety of lead-free bismuth salt glass powders with di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com