Thin film packaging method and structure

A technology for thin film encapsulation and encapsulation of devices, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc. The effect of improving the bending resistance and reducing the deviation of the thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In this application, the preparation methods of the inorganic layer and the organic material layer are all prepared by existing methods.

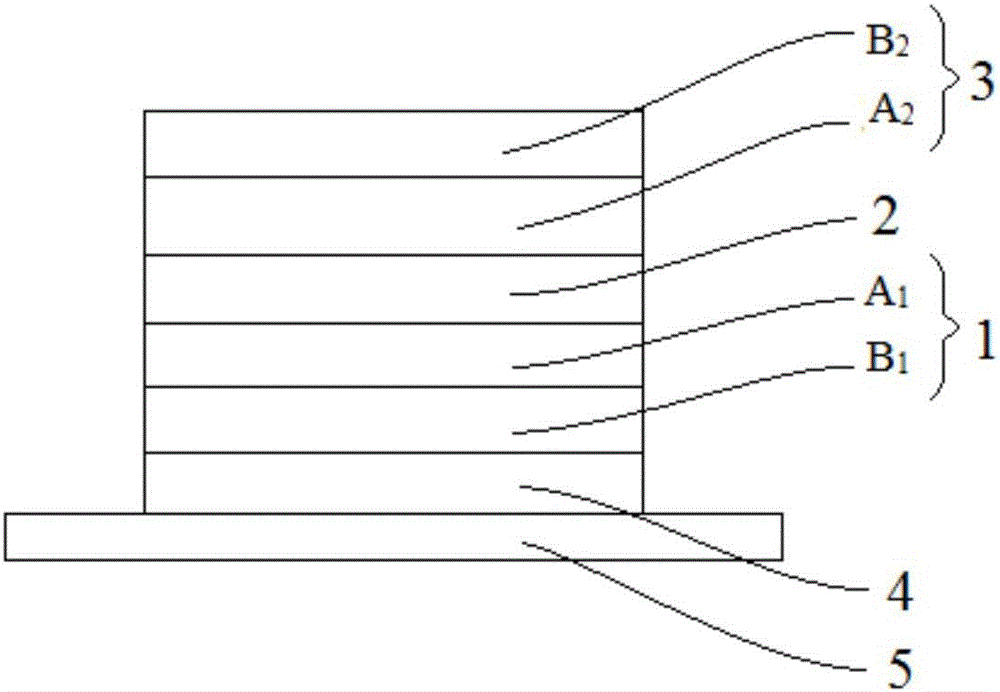

[0053] The present application also relates to a thin-film packaging structure. The thin-film packaging structure is arranged on the surface of the packaging device. The surface of the packaging device is sequentially provided with a first inorganic material layer, an organic material layer and a second inorganic material layer. The first inorganic material layer and the second The inorganic material layer includes an inorganic layer B prepared by atomic layer deposition, and at least one surface of the inorganic layer B is provided with an inorganic layer A prepared by physical vapor deposition or chemical vapor deposition.

[0054] As an improvement of the thin film packaging structure of the present application, the material of the inorganic layer B prepared by atomic deposition is the same as that of the inorganic layer A prepared...

Embodiment 1

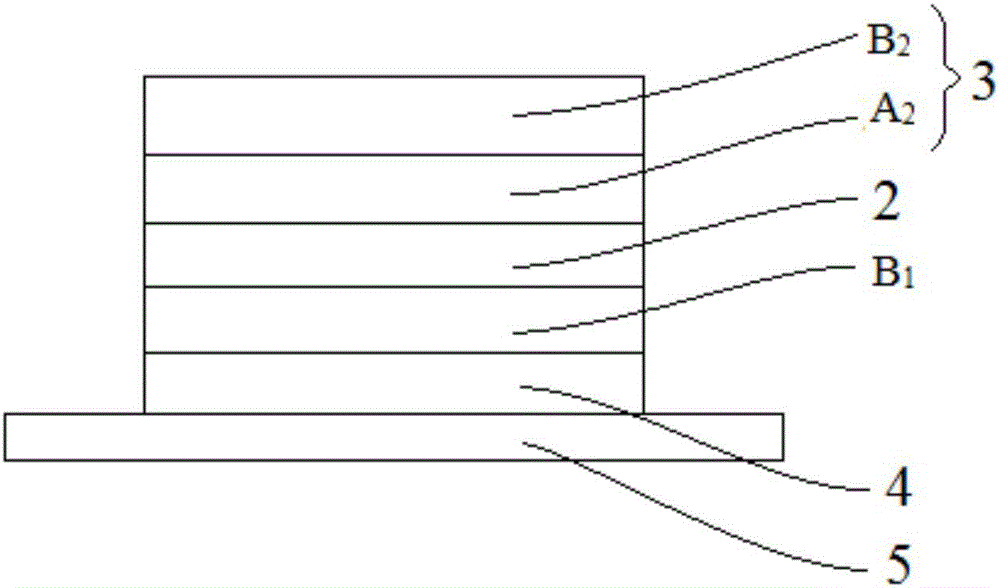

[0061] A thin-film encapsulation structure comprising a first inorganic material layer 1, an organic material layer 2 and a second inorganic material layer 3 from the OLED surface upwards, the specific structure, material and thickness of which are shown in Table 1;

[0062] Table 1:

[0063]

[0064] Among them, 0

[0065] Preparation Process:

[0066] First, the top-emitting OLED device and the driving backplane are prepared, and the device to be packaged is placed in a physical vapor deposition equipment, and an aluminum target is used to deposit the inorganic layer A by reactive sputtering 1 , the deposition thickness is 80nm; after the deposition is completed, it is sent to the atomic layer deposition equipment, and the precursors are trimethylaluminum TMA and H 2 O, the precursor reacts to form the inorganic layer B 1 , the deposition thickness is 50nm; repeat the physical vapor deposition process, and then deposit 80nm thick AlO x as an inorganic layer C ...

Embodiment 2

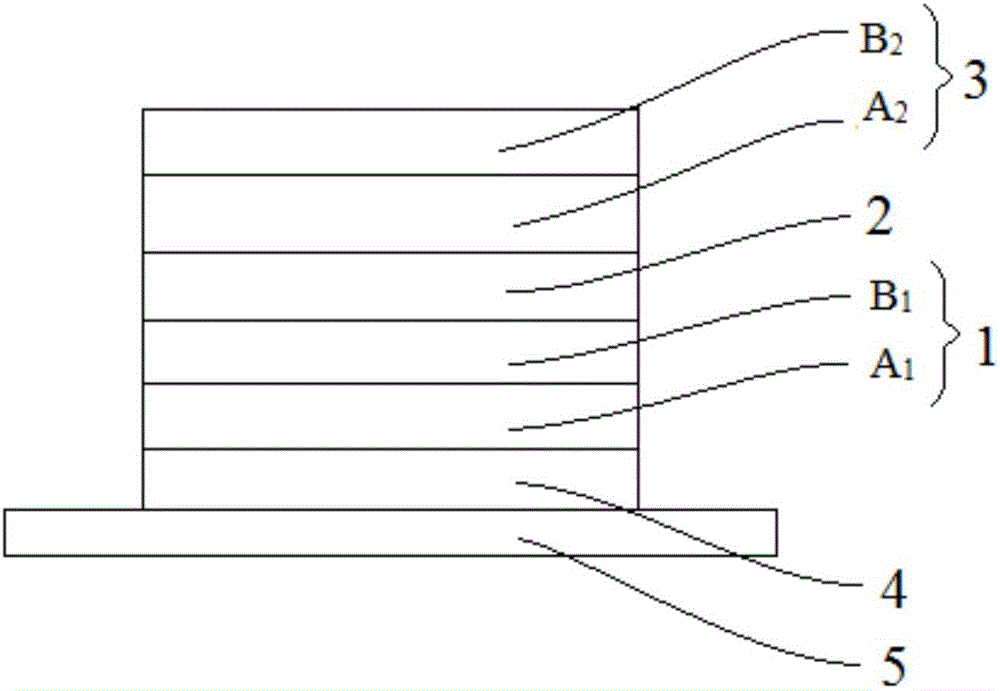

[0070] A thin-film encapsulation structure comprising a first inorganic material layer 1, an organic material layer 2 and a second inorganic material layer 3 sequentially from the surface of the OLED, and its specific structure, material and thickness are shown in Table 2;

[0071] Table 2:

[0072]

[0073]

[0074] Among them, 0

[0075] Preparation Process:

[0076] First, prepare the top-emitting OLED device and the driving backplane, place the device to be packaged in a chemical vapor deposition equipment, use silane and laughing gas as the reaction gas, and react to form an inorganic layer A 1 , the deposition thickness is 100nm; after the deposition is completed, it is sent to the atomic layer deposition equipment. The precursor is tetraethyl orthosilicate and oxygen, which react to form the inorganic layer B 1 , the deposition thickness is 50nm; repeat the chemical vapor deposition process, and then deposit 100nm thick SiO x as an inorganic layer C 1 , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com