Conductive adhesive for circuit board, single/double-sided multi-layer printed circuit board, and production method

A kind of conductive adhesive and circuit board technology, applied in the field of conductive adhesive, can solve the problems of surface layer copper foil damage, circuit short circuit, affecting resistance value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

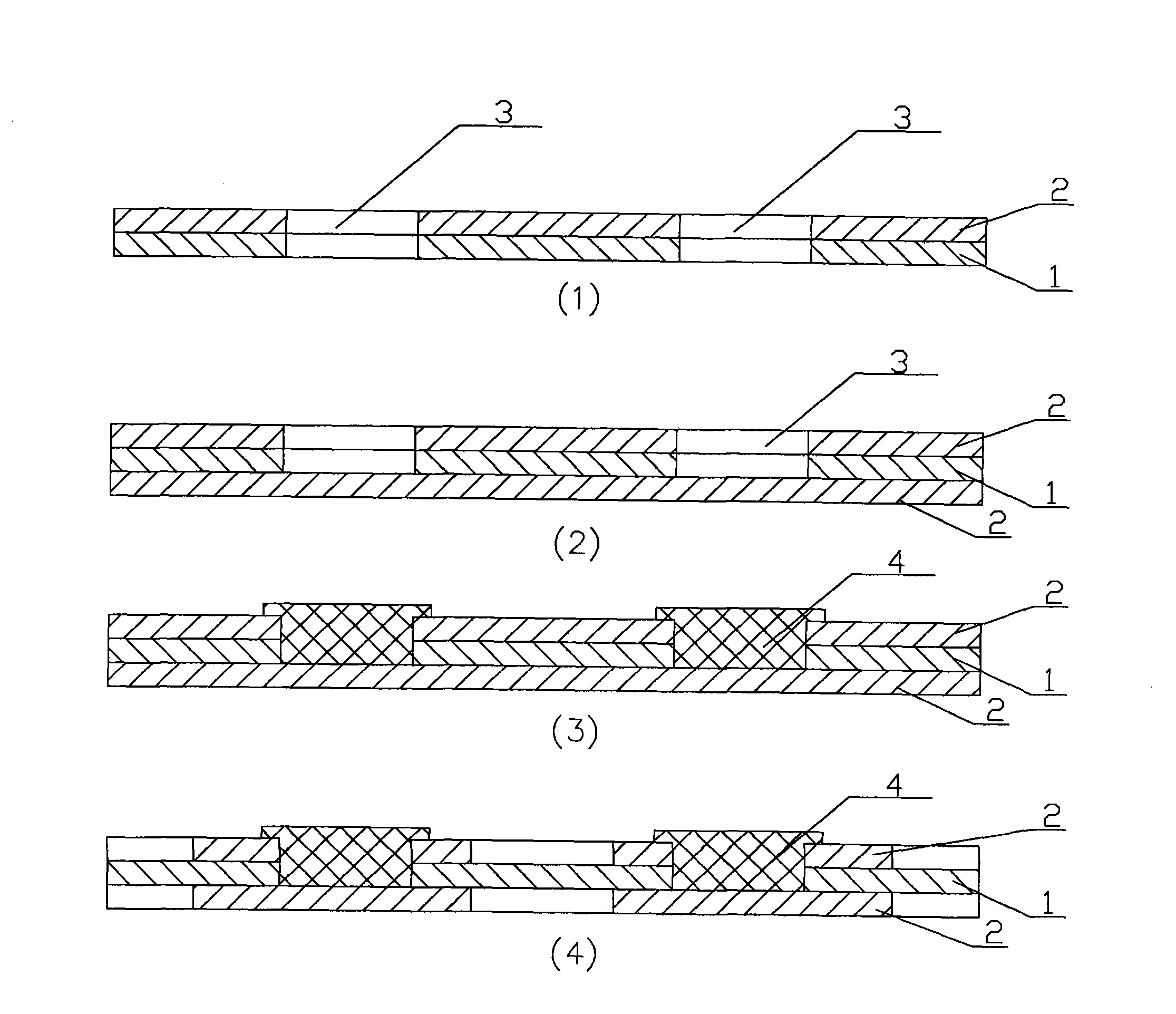

[0071] Implementation plan 1 (production of single-sided panel)

[0072] Substrate: 0.1MM polyimide without hot melt adhesive;

[0073] Printing tool: 77T (ie 200 mesh) screen;

[0074] Operation method:

[0075] 1. After cutting the substrate, remove the dust and oil stains on the surface of the substrate;

[0076] 2. Use 77T screen to print the circuit directly on the surface of the substrate;

[0077] 3. After printing, dry at 130°C-150°C for 30 minutes to obtain the circuit layer;

[0078] 4. Apply the methods known in the industry to make the protective layer and the character layer, and then a complete circuit board can be obtained.

Embodiment approach 2

[0079] Implementation plan 2 (one of the production of double-sided panels)

[0080] Substrate: 1. Polyimide substrate coated with semi-cured hot melt adhesive on one side with a thickness of 0.1mm (the thickness of the hot melt adhesive is 30um);

[0081] 2. 18UM copper foil

[0082] Aperture diameter of via hole: 0.5MM

[0083] Printing tool: 77T (ie 200 mesh) screen

[0084] Operation method 1. Firstly, the polyimide base material coated with semi-cured hot-melt resin with a thickness of 30um is first processed by mechanical stamping, mechanical drilling or laser drilling according to the engineering data to process conduction holes and positioning holes, etc.;

[0085] 2. Press the base material with the processed via hole and the copper foil together, the pressing conditions are temperature 180 ℃, pressure 100 kg, time 60 seconds;

[0086] 3. Curing the laminated substrate at 150°C for 60 minutes;

[0087] 4. Use the well-known corrosion method in the industry to make...

Embodiment approach 3

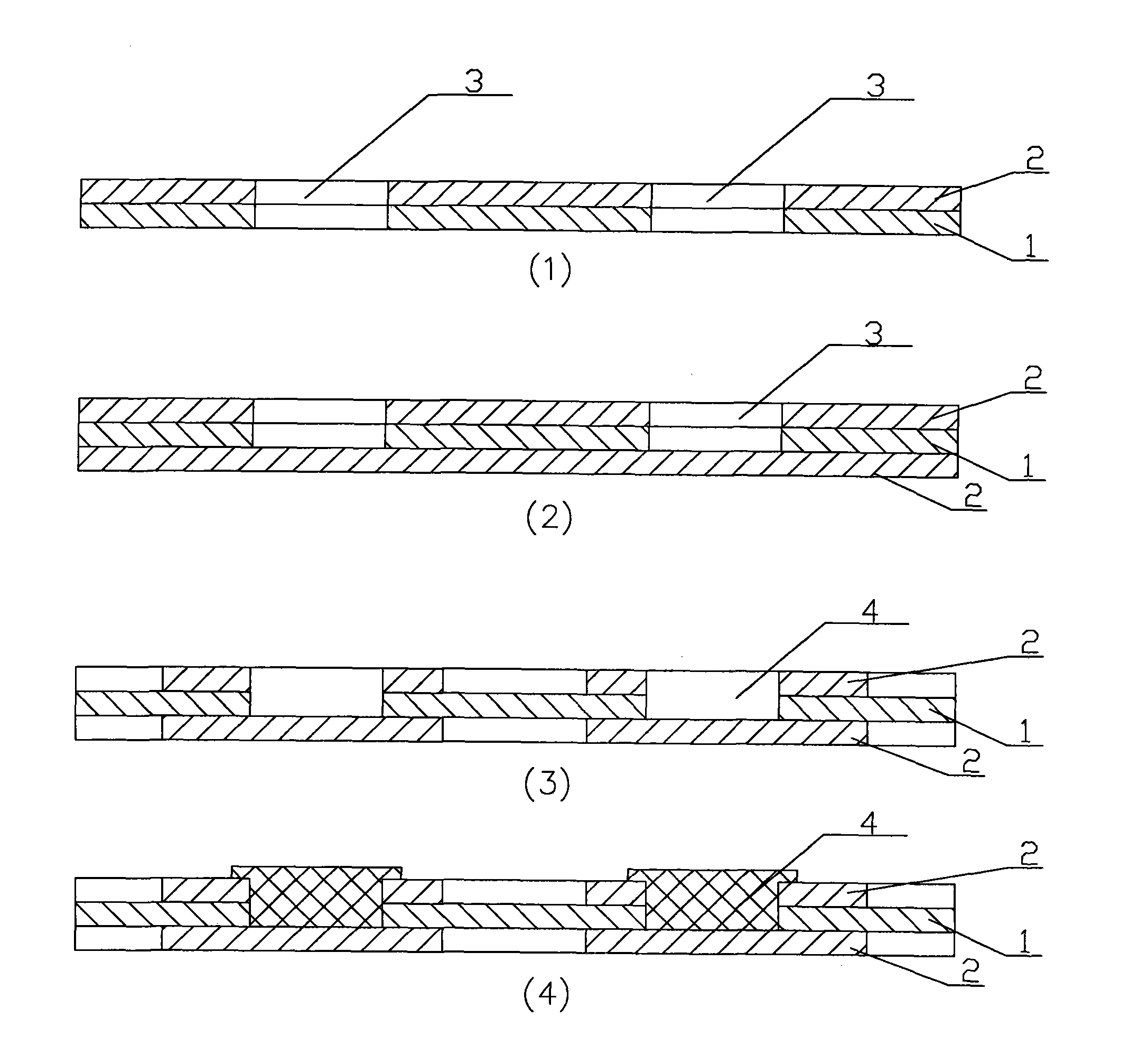

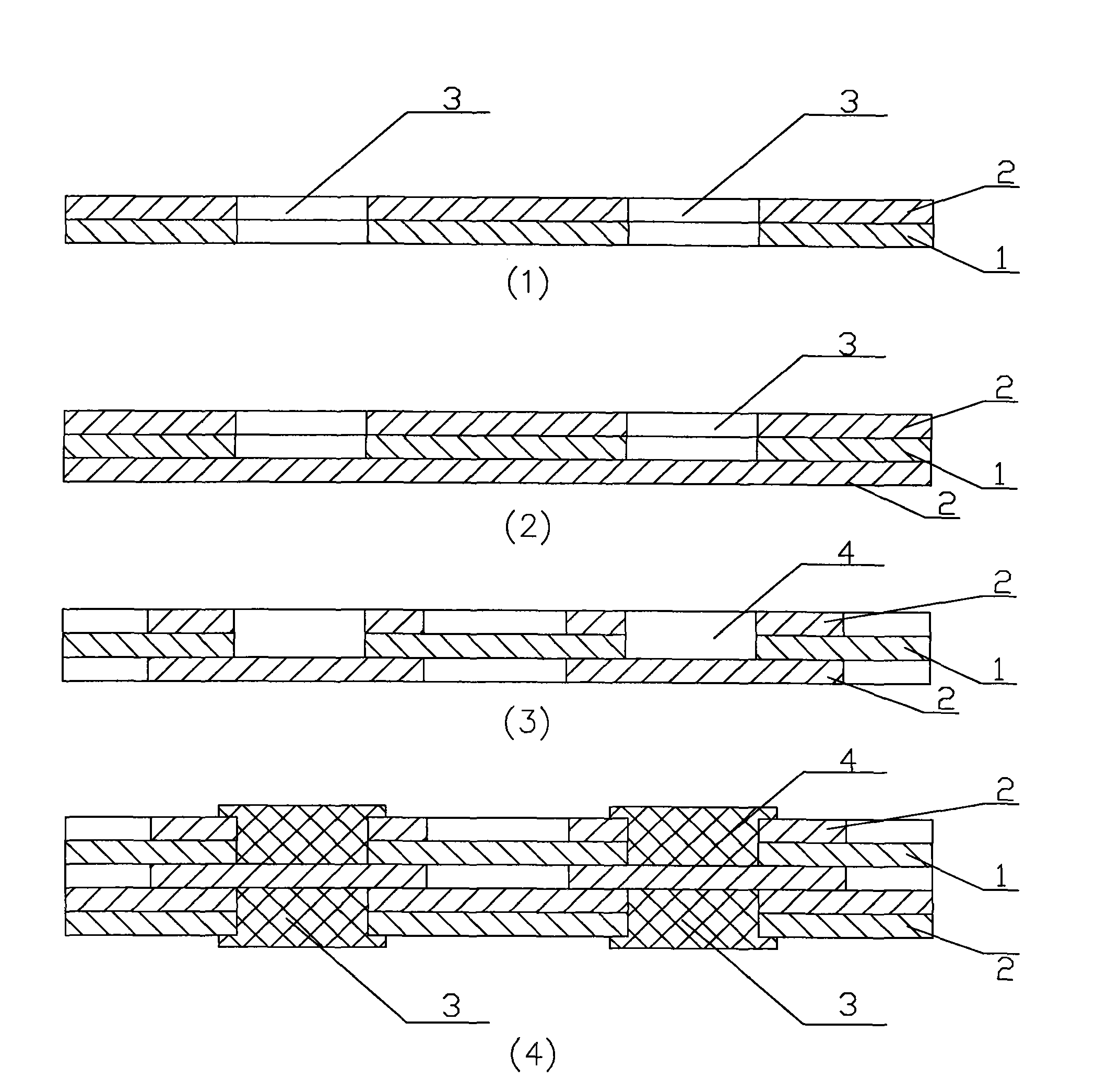

[0091] Implementation plan three (two-sided panel production)

[0092] Substrate: 1. Polyimide substrate coated with semi-cured hot-melt adhesive on both sides with a thickness of 10.1mm (the thickness of the hot-melt adhesive is 30um)

[0093] 2. 18UM copper foil;

[0094] Aperture diameter of via hole: 0.5MM.

[0095] Printing tool: 77T (ie 200 mesh) screen.

[0096] Operation method: 1. Pre-press one side of copper foil on one side of the double-sided glue-coated substrate, the conditions are: temperature 80-100 ℃, pressure 60-80 kg, time 15-25 seconds.

[0097] 2. Then process the through holes and positioning holes according to the engineering data.

[0098] 3. Cover the other side (the side without copper foil) with copper foil, and press it into shape by pressing machine. The pressing conditions are: temperature 180°C, pressure 100-120 kg, time 80 seconds.

[0099] 4. Then, the laminated double-sided copper foil substrate is cured at 150°C for 60 minutes to produce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com