Preparation method of double-rare-earth-ion tantalite high-temperature ceramic

A high-temperature ceramic and tantalate technology, which is applied in the field of preparation of double rare earth ion tantalate high-temperature ceramics, can solve problems such as cracks in high-temperature ceramic materials, loss of thermal barrier coating ceramic materials, and mismatching thermal expansion coefficients. The effect of good high temperature thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

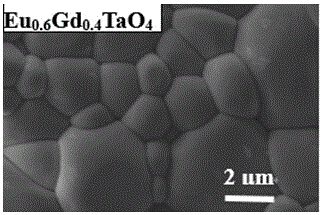

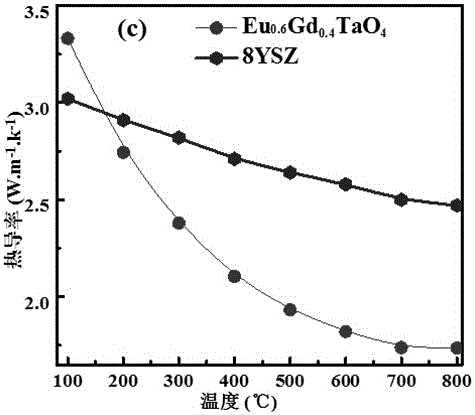

[0024] A high-temperature-resistant, anti-oxidation, anti-wear double rare earth ion tantalate high-temperature ceramic material (Eu 0.6 Gd 0.4 TaO 4 ) and a preparation method thereof, specifically comprising the following steps:

[0025] Weigh 5.2788g of europium oxide, 3.6249g of gadolinium oxide, and 11.0473g of tantalum oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 400r / min, and the ball milling time is 120min), and the balls are ground The mixture was dried at 74°C for 16 hours and passed through a 300-mesh sieve, and then pre-fired at 1650°C for 5 hours.

[0026] After calcining the raw materials for the first time, grind the mixture to fine particles (10-30 μm), dissolve it in absolute ethanol again, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 400r / min, and the ball milling time is 120min) , the ball-milled mixture was dried at 74°C for 16 hours and p...

Embodiment 2

[0029] A kind of novel high temperature resistance described in this embodiment, anti-oxidation, anti-abrasion double rare earth ion tantalate high temperature ceramic material (La 0.75 SM 0.25 TaO 4 ) and a preparation method thereof, specifically comprising the following steps:

[0030] Weigh 4.8871g of lanthanum oxide, 1.7435g of samarium oxide, and 8.8378g of tantalum oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 350r / min, and the ball milling time is 140min), and the balls are ground The mixture was dried at 65°C for 20 hours and passed through a 300-mesh sieve, and then pre-fired at 1550°C for 8 hours.

[0031] After calcining the raw materials for the first time, grind the mixture to fine particles (10-30 μm), dissolve it in absolute ethanol again, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 350r / min, and the ball milling time is 140min) , the ball-mil...

Embodiment 3

[0033] A new type of high temperature resistance described in this embodiment, anti-oxidation, anti-wear double rare earth ion tantalate high temperature ceramic material (Y0.5 Dy 0.5 TaO 4 ) and a preparation method thereof, specifically comprising the following steps:

[0034] Weigh 5.6452g of yttrium oxide, 9.3249g of dysprosium oxide, and 22.0946g of tantalum oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 300r / min, and the ball milling time is 180min), and the balls are ground The mixture was dried at 60°C for 24 hours and passed through a 300-mesh sieve, and then pre-fired at 1650°C for 10 hours.

[0035] After calcining the raw materials for the first time, grind the mixture to fine particles (10-30 μm), dissolve it in absolute ethanol again, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 300r / min, and the ball milling time is 180min) , the ball-milled mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com